Excimer lamp

An excimer lamp, a part of the technology, is applied in the field of excimer lamps for lighting openings, which can solve the problems of inability to correctly measure the amount of light, obstruction of creeping discharge 12, etc., and achieve the effect of easy formation and easy lighting openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

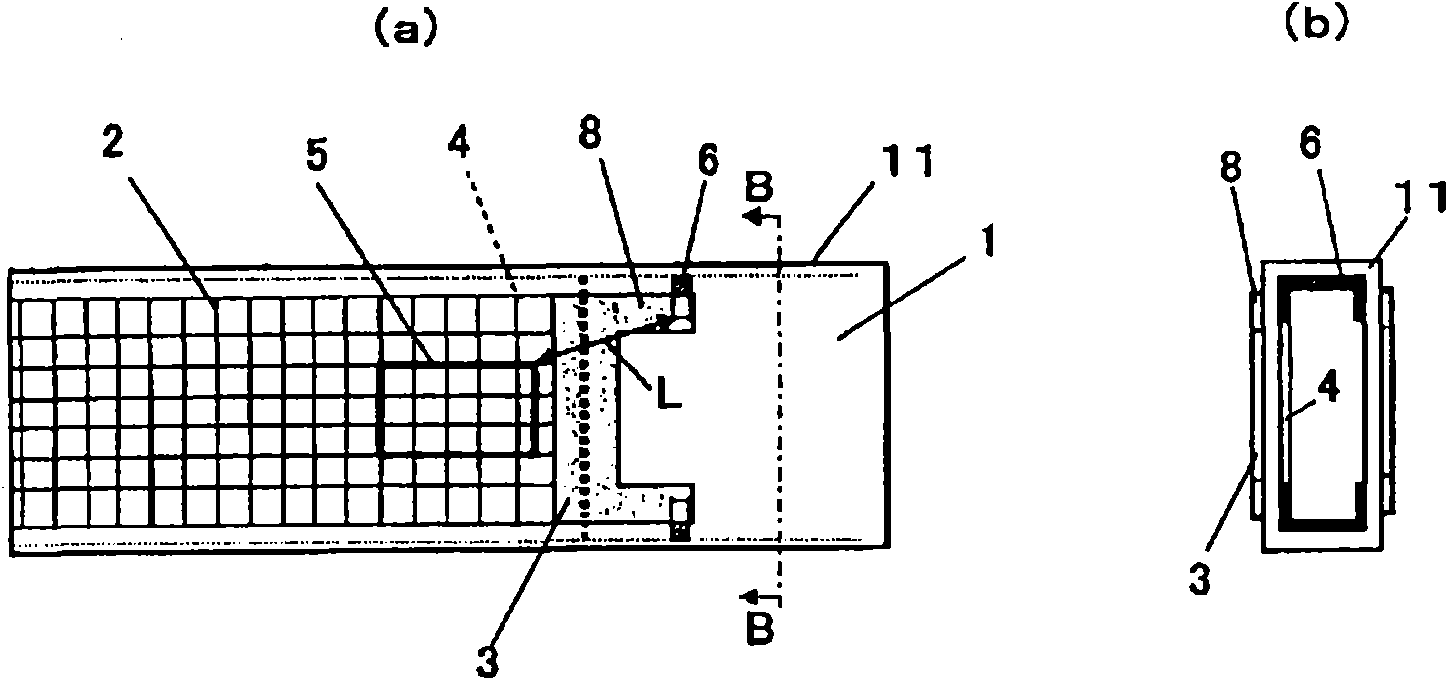

[0032] figure 1 It is a schematic diagram showing the first embodiment of the excimer lamp of the present invention, figure 1 (a) is a top view, and figure 1 (b) is its B-B section view.

[0033] In the figure, on the monolithic electrode (べタ-shaped electrode) 3 formed at the end of the light-transmitting electrode 2, there are integrally formed electrodes extending in the direction opposite to the direction of the light-transmitting electrode in the direction of the tube axis at its upper and lower ends. Dendritic electrodes 8,8.

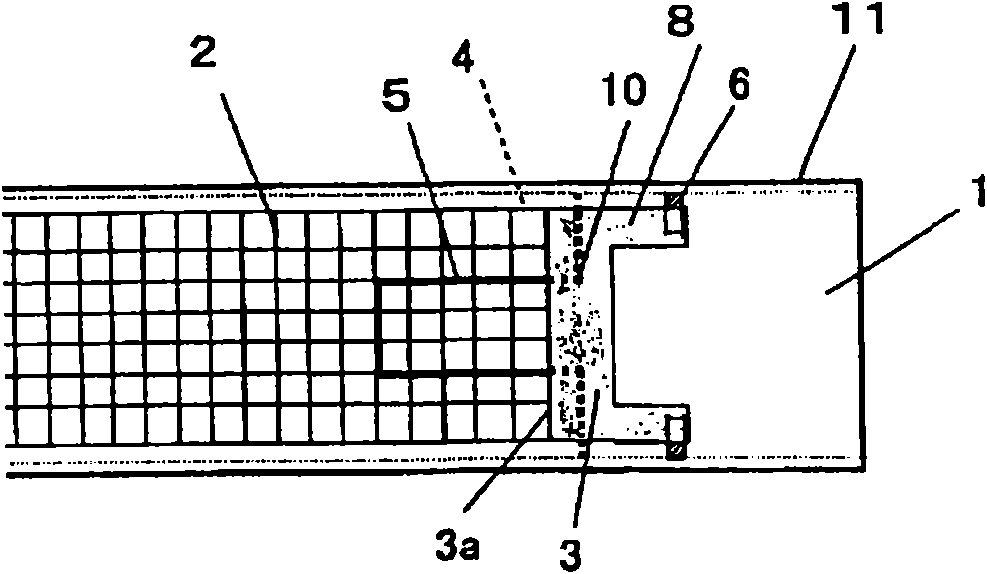

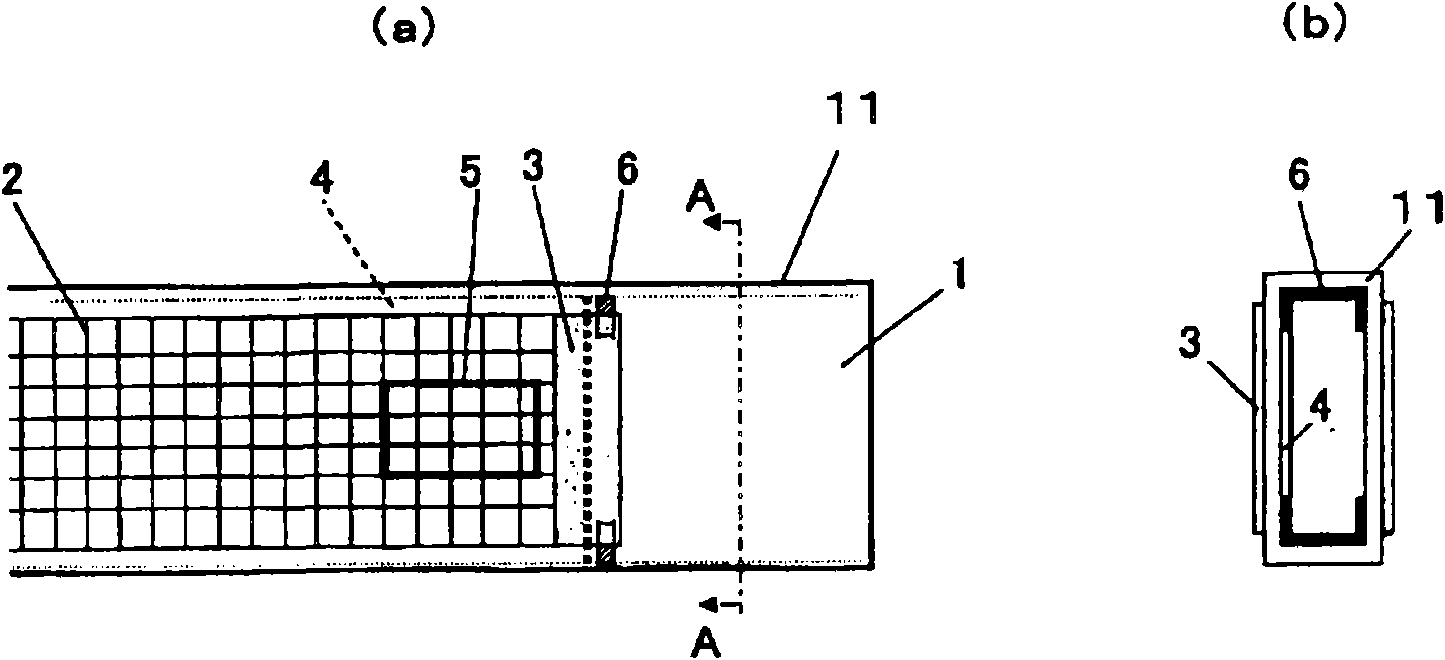

[0034] In addition, on the inner surface of the discharge vessel 11 corresponding to the portion where the dendritic electrode 8 is formed, the starting auxiliary electrode 6 is formed so as to overlap a part thereof. For other structures, with image 3 Same as shown.

[0035] The dendritic electrodes 8, 8 have the effect of increasing the distance L between the lighting opening 5 and the starting auxiliary electrode 6, so even if the lighti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com