Power module

A technology for power modules and power devices, which is applied to semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., and can solve problems such as overheating of power devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

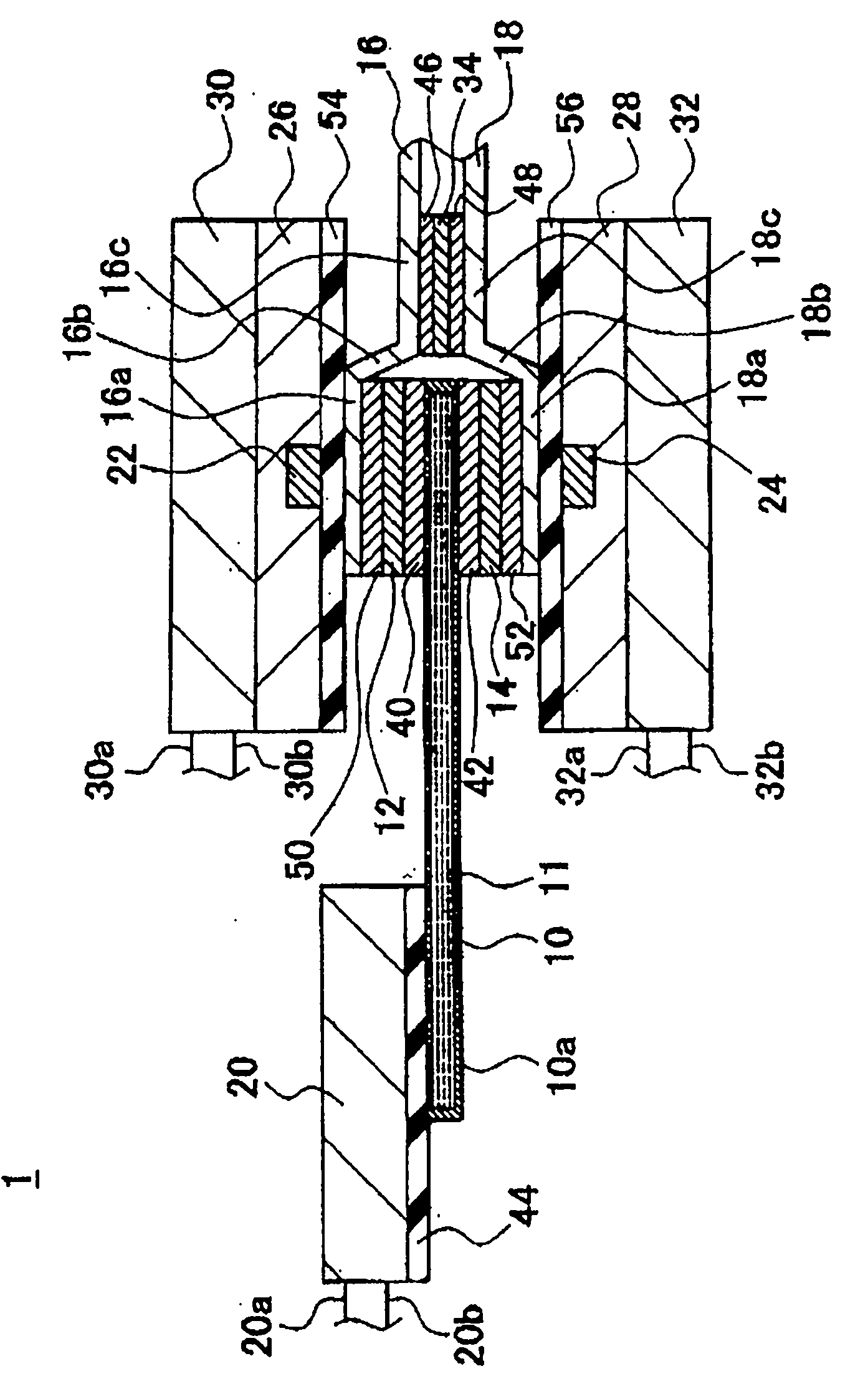

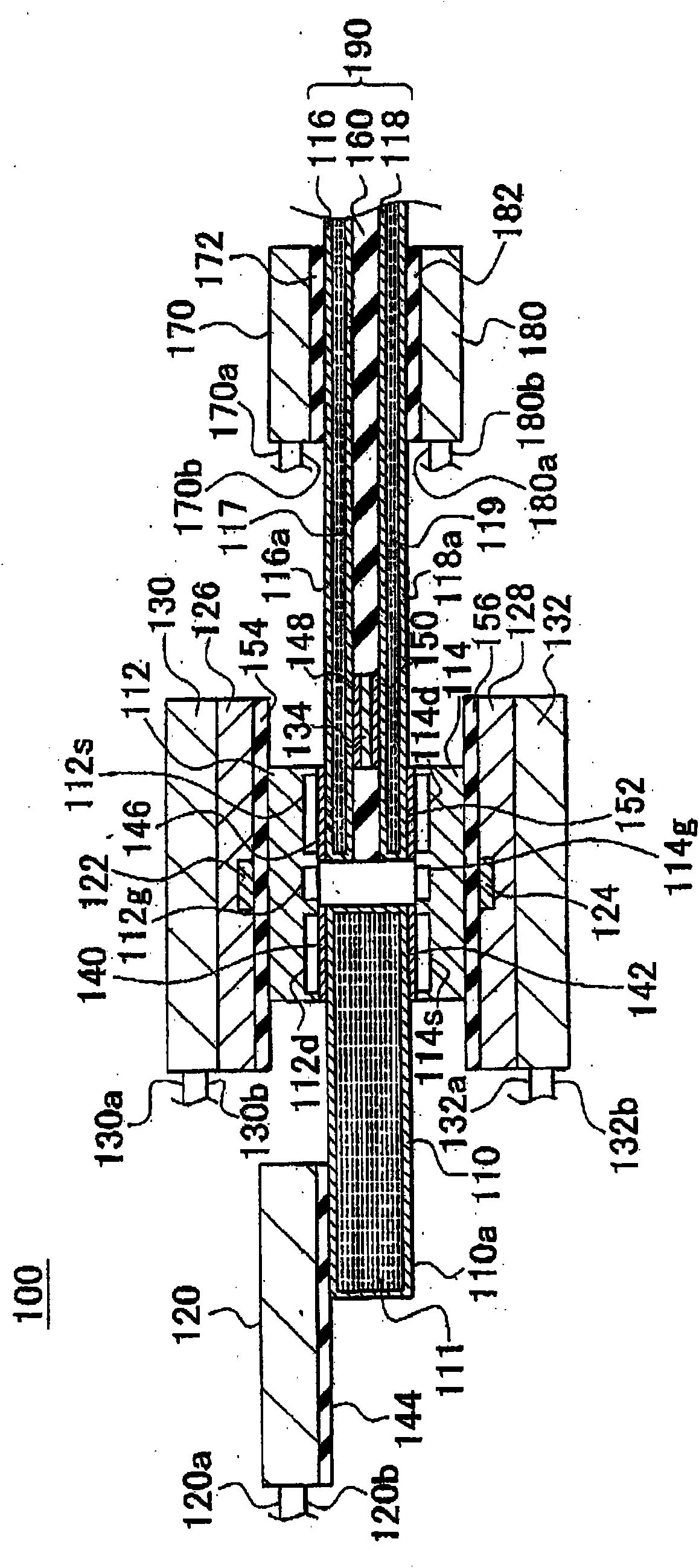

[0029] The technical features of the exemplary embodiments described below are summarized as follows.

[0030] (1) Use vertical IGBTs or FETs for power devices.

[0031] (2) A plate-like self-heating tube or graphite material is used for the output electrode.

[0032] (3) The output electrode cooler is made of silicon.

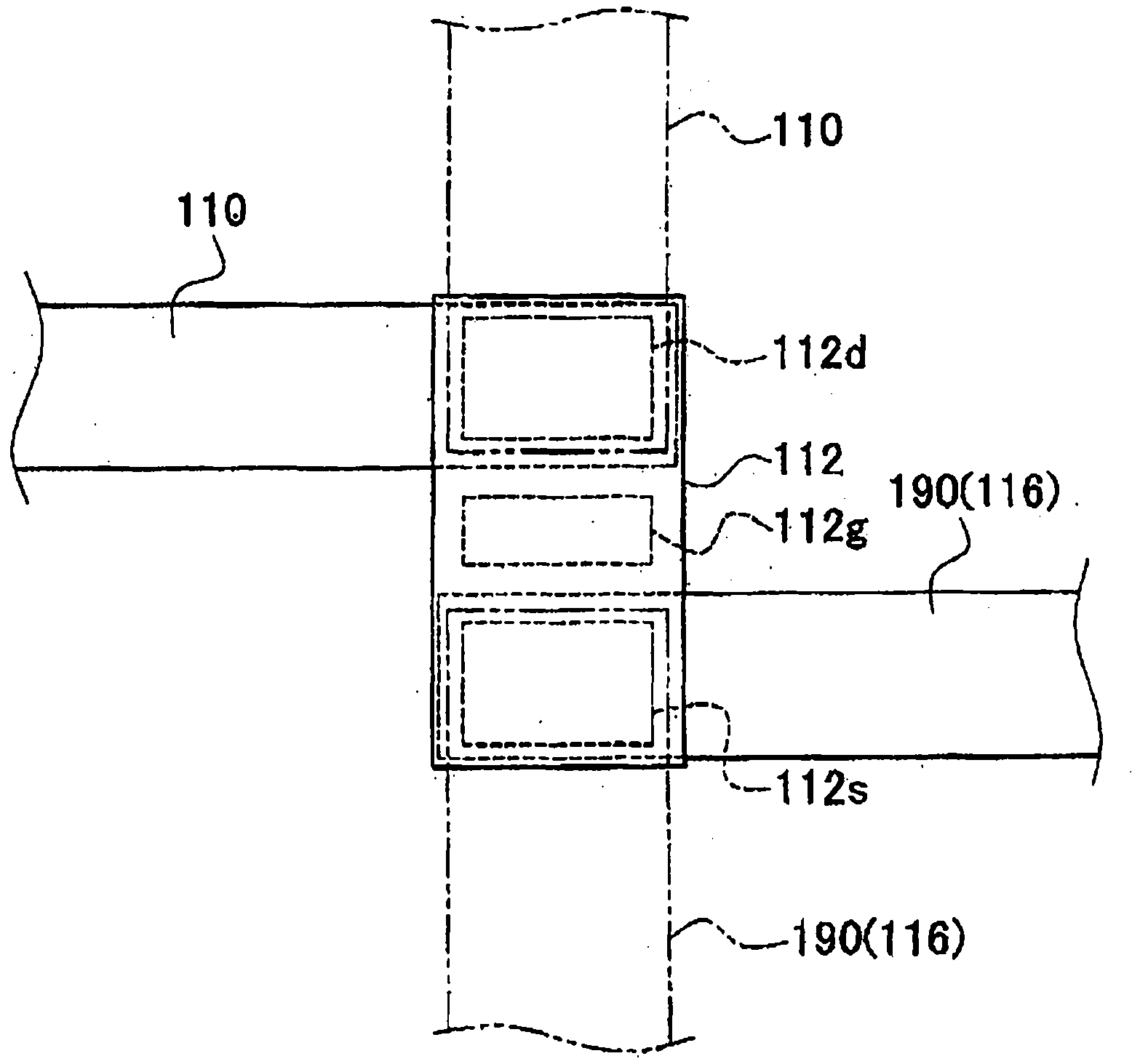

[0033] (4) The N-electrode and the P-electrode are preferably arranged in parallel and facing each other, so as to effectively generate mutual inductance that reduces parasitic inductance.

[0034](5) Making the facing portion of the N electrode and the P electrode as long as possible increases the portion where the mutual inductance that reduces the parasitic inductance can be obtained, so that the two electrodes are preferably arranged facing each other from the vicinity of the power device as much as possible. close to each other.

[0035] (6) Use SrTiO 3 A sheet-type capacitor as a main component serves as a capacitor provided between an N electrode an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com