Device and method for preparing anhydrous lower alcohol mixture by using Fischer-Tropsch synthesis by-product light alcohols

A low-carbon mixed alcohol and Tropol synthesis technology, which is applied in the chemical industry, can solve the problems of methanol loss, difficult operation, and substandard alcohol content, and achieve the effects of improving product quality, increasing economic value, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

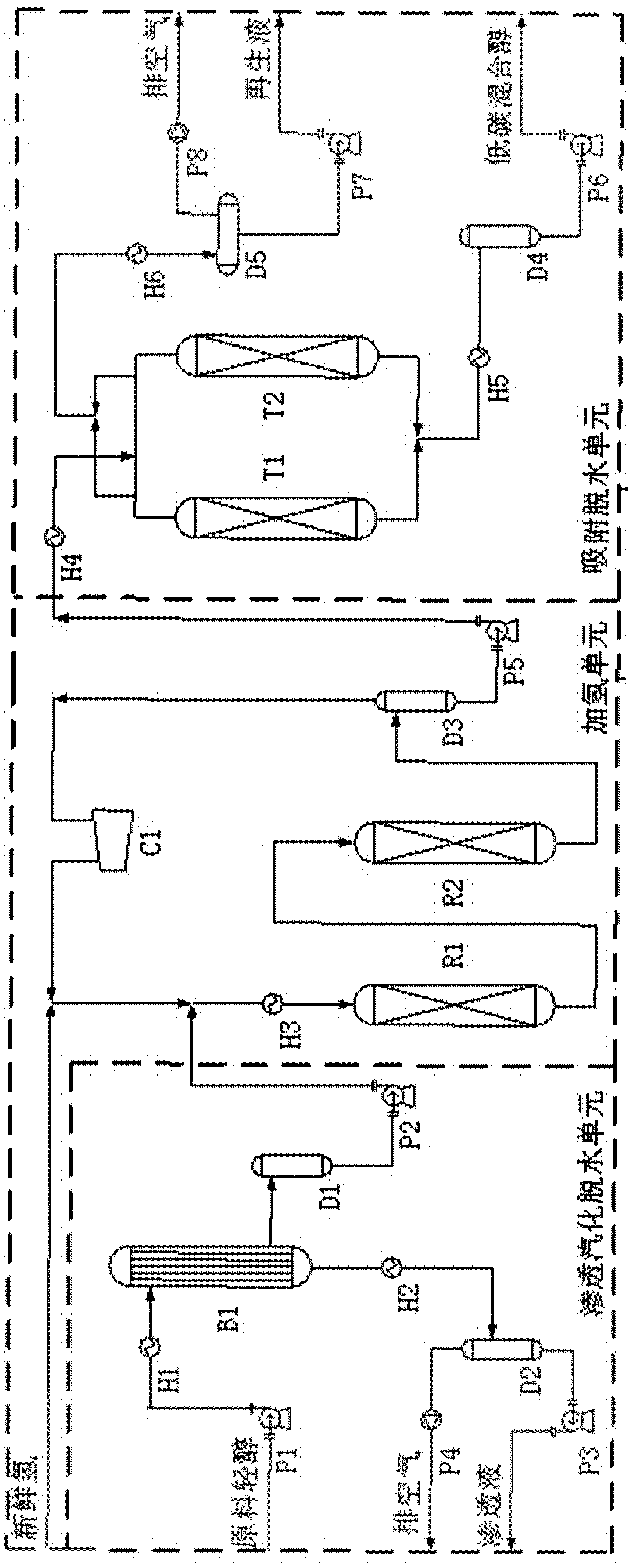

[0048] The present invention comprehensively considers the by-product light alcohol composition of Fischer-Tropsch synthesis and the adaptability of the existing dehydration technology of the water-containing azeotropic system, and proposes a reasonable process flow, which uses pervaporation membrane separation method for preliminary dehydration, and then undergoes two-step hydrogenation to dehydrate non-alcoholic alcohol. Alcohol oxygen-containing organic compounds are converted into alcohols, and finally deep dehydration is carried out by molecular sieve adsorption.

[0049] Such as figure 1As shown, the device for preparing anhydrous low-carbon mixed alcohols using Fischer-Tropsch synthesis by-product light alcohols in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com