Industrial automatic beading machine

A bead stringing machine and automatic technology, which is applied in the field of bead stringing machines, can solve the problems of high labor costs and low efficiency, and achieve the effects of improving production efficiency, easy operation, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

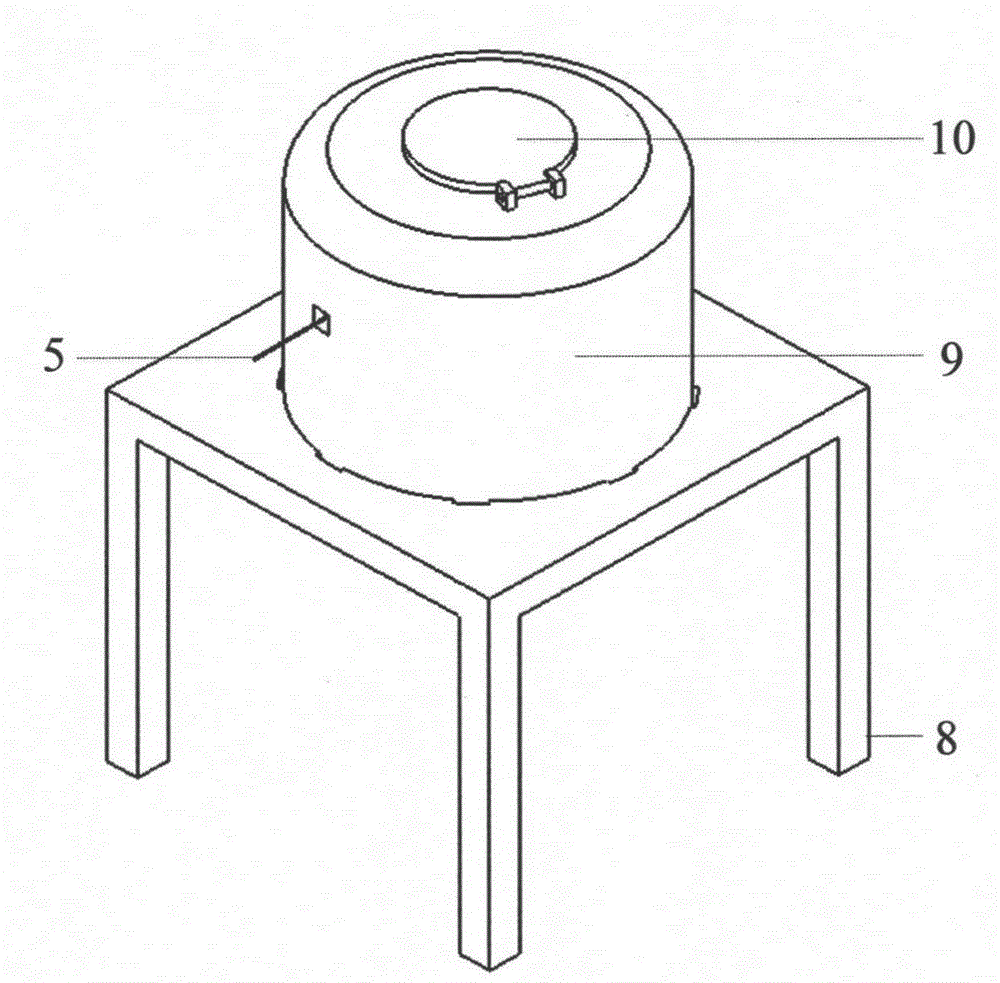

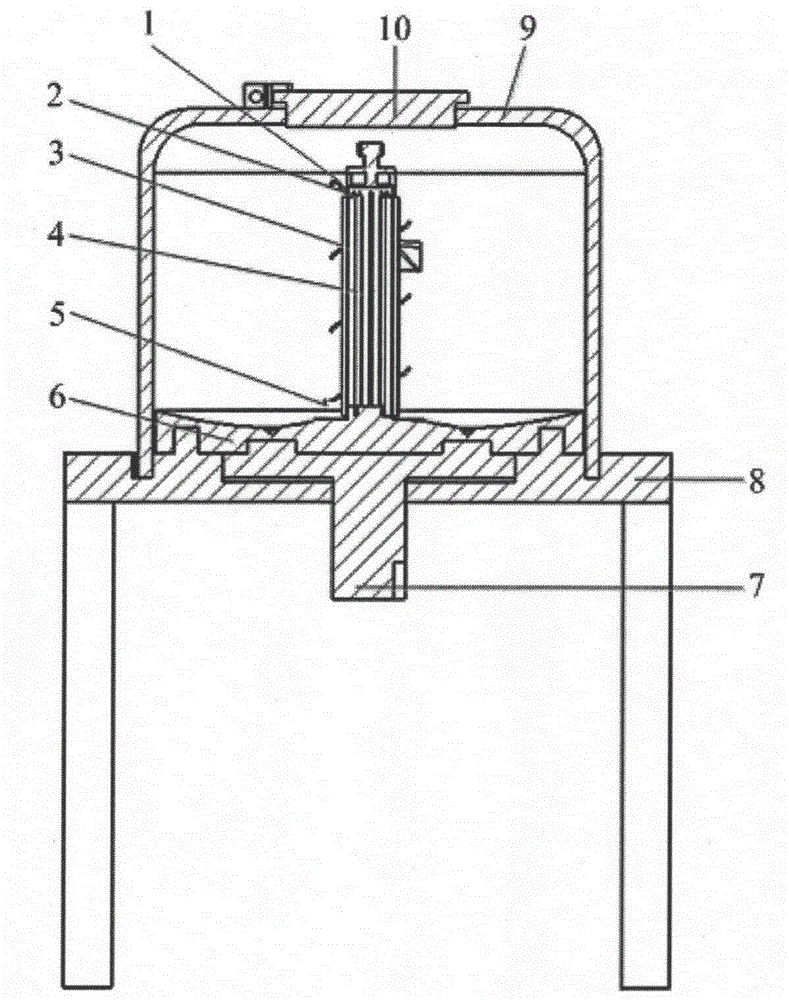

[0028] figure 1 and figure 2 The three-dimensional schematic diagram and cross-sectional view of the industrial automatic bead stringing machine provided by the present invention respectively, the industrial automatic bead stringing machine is composed of a rotating knob 1, a spring 2, a movable dial 3, a rotating shaft 4, a guide wire 5, a rotating disc 6, and a transition disc 7. Composition of frame 8, outer cover 9, opening cover plate 10, etc.

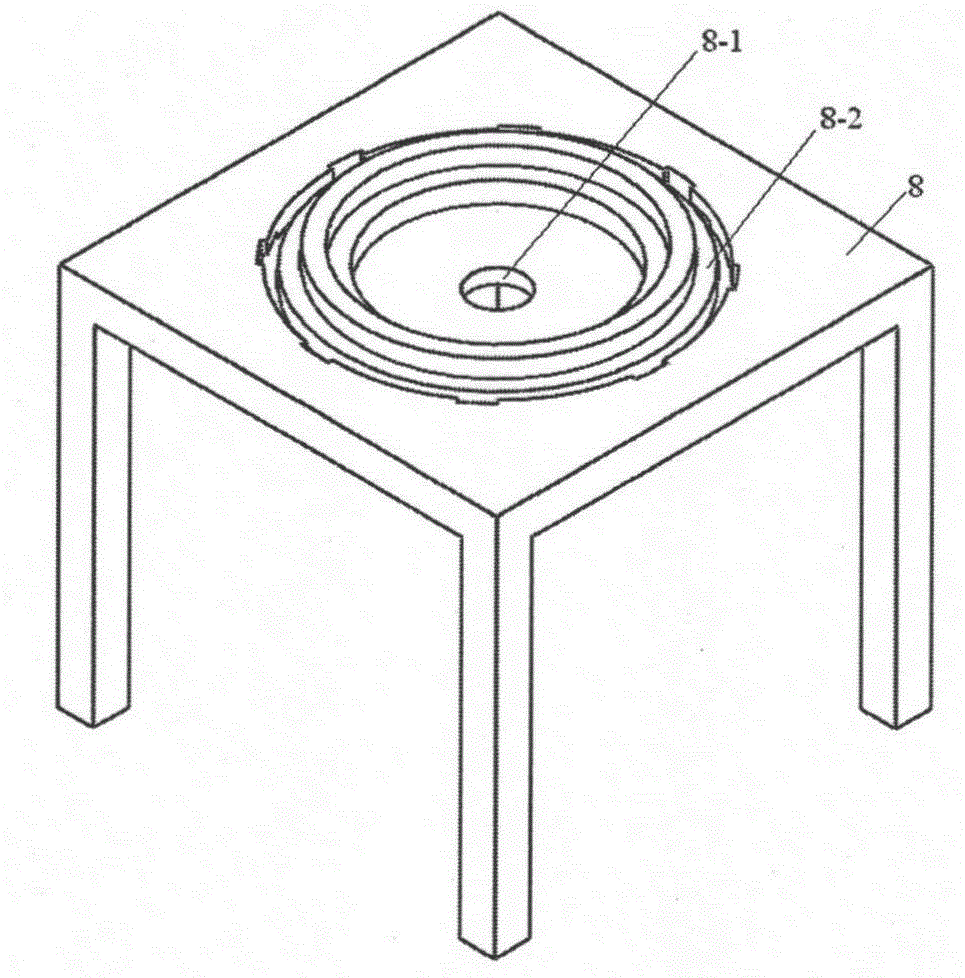

[0029] combine image 3 , the center of the frame 8 is processed with a circular hole 8-1, so that the transition plate 7 is installed and fixed; the concentric periphery of the circular hole 8-1 is processed with a circular slide table 8-2, so that the rotating disc 6 rotates; the rotating disc 6 Installed on the transition plate 7 and can rotate around the circular slide table 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com