Method for synthesizing epoxy propane by loading catalysts different in grain size

A technology of propylene oxide and catalyst, which is applied in the field of filling catalysts with different particle sizes to synthesize propylene oxide, which can solve the problems of low effective utilization rate of hydrogen peroxide, uneven bed temperature, complex reactor structure, etc., and achieves increased equipment investment, reaction The effect of slow speed and not easy to overheat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

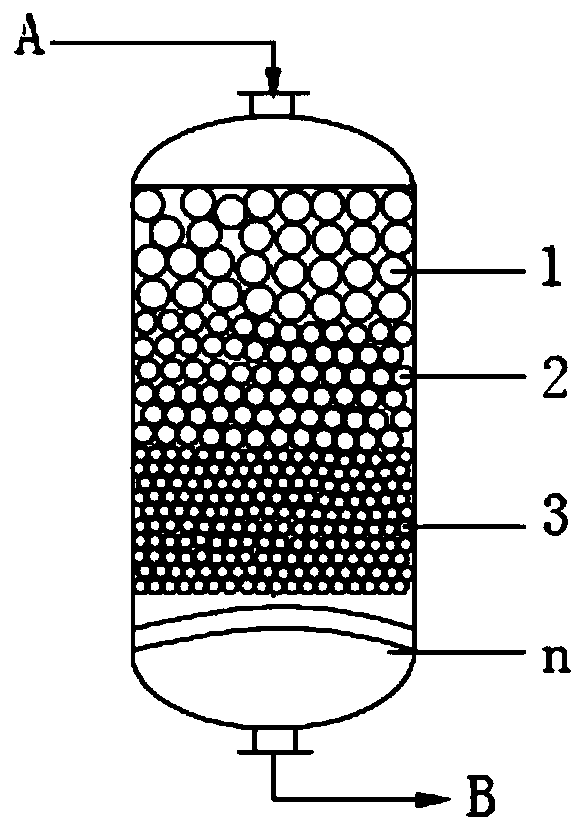

[0037] Pack ten kinds of titanium-silicon molecular sieves with different particle sizes along the flow direction of the reaction material according to the particle size arrangement in the table below:

[0038] layers

[0039] Control the molar ratio of hydrogen peroxide: propylene: methanol to be 1:5:20, and the space velocity of the total liquid weight is 20h -1 Pump into the tubular fixed-bed reactor, the circulating water inlet temperature is 45°C, and the reaction pressure is 4.0MPa. The highest point temperature of the catalyst bed was 54°C, the lowest point temperature was 46°C, and the bed temperature rose by 8°C as detected by a thermocouple. The analysis results showed that the conversion rate of hydrogen peroxide was 99.5%, and the yield of propylene oxide was 92.7%.

Embodiment 2

[0041] Two kinds of titanium-silicon molecular sieves with different particle sizes are packed in the following table along the flow direction of the reactant material:

[0042] layers

[0043] Control the molar ratio of hydrogen peroxide: propylene: methanol to be 1:1:5, and the space velocity of the total liquid weight is 5h -1 Pump into the tubular fixed-bed reactor, the circulating water inlet temperature is 50°C, and the reaction pressure is 1.0MPa. The highest point temperature of the catalyst bed was 65°C and the lowest point temperature was 55°C as detected by a thermocouple, and the temperature rise of the bed was 10°C. The analysis results showed that the conversion rate of hydrogen peroxide was 98.5%, and the yield of propylene oxide was 91.5%.

Embodiment 3

[0045] Four kinds of titanium-silicon molecular sieves with different particle sizes are packed in the following table along the flow direction of the reactant material:

[0046] layers

[0047] Control the molar ratio of hydrogen peroxide: propylene: methanol to be 1:3:15, and the space velocity of the total liquid weight is 10h -1 Pump into the tubular fixed-bed reactor, the temperature of the circulating water is 40°C, and the reaction pressure is 2.5MPa. The highest point temperature of the catalyst bed was 48°C, the lowest point temperature was 41°C, and the bed temperature rose by 7°C as detected by a thermocouple. The analysis results showed that the conversion rate of hydrogen peroxide was 99.6%, and the yield of propylene oxide was 94.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com