Ultrasonic ozone combined cleaning equipment used for kitchens and cleaning method thereof

A cleaning equipment, ultrasonic technology, applied in kitchen ultrasonic ozone combined cleaning equipment and its cleaning field, can solve the problems of large water consumption, poor adaptability, environmental pollution, etc., achieve remarkable effect and kill bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

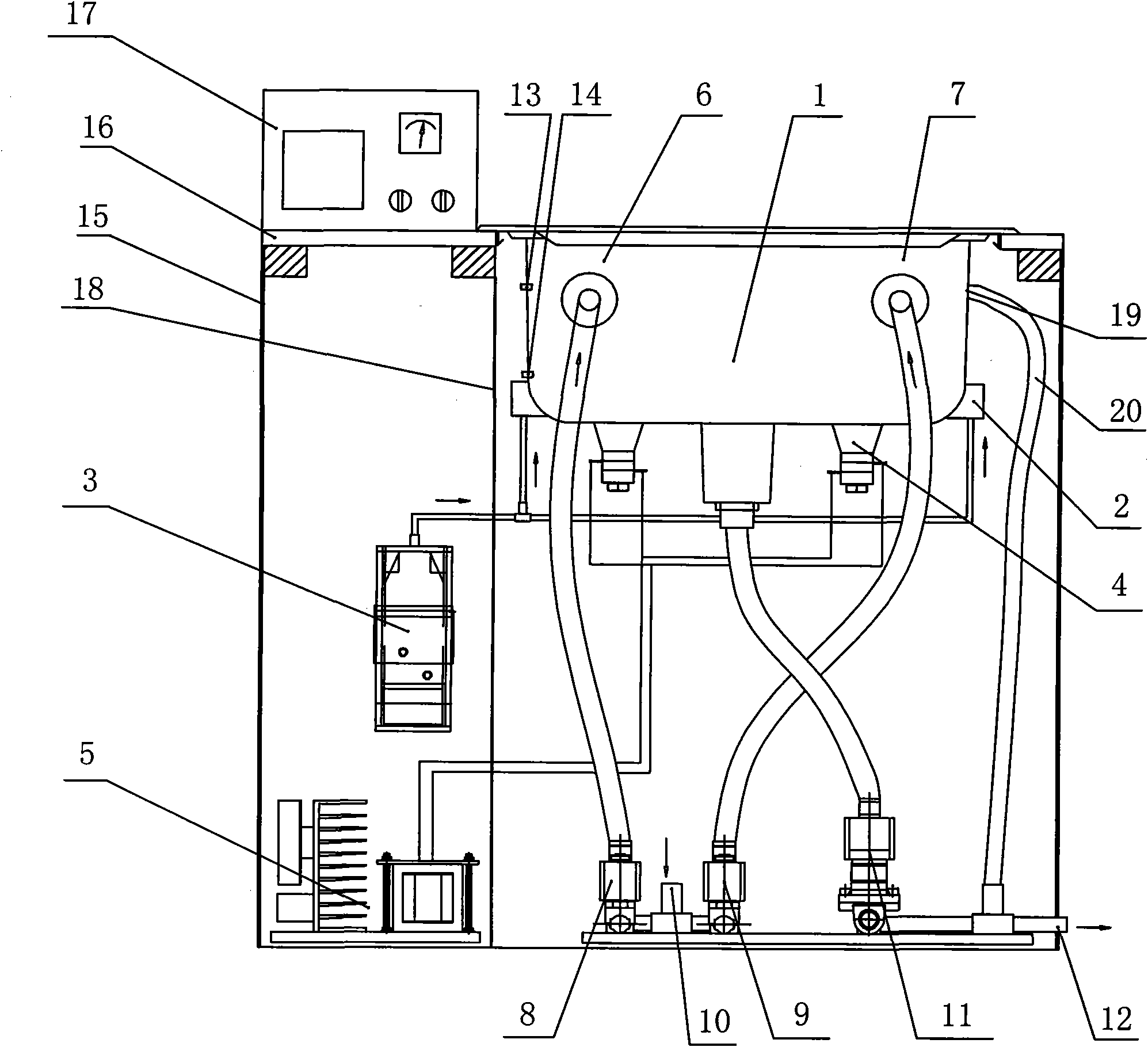

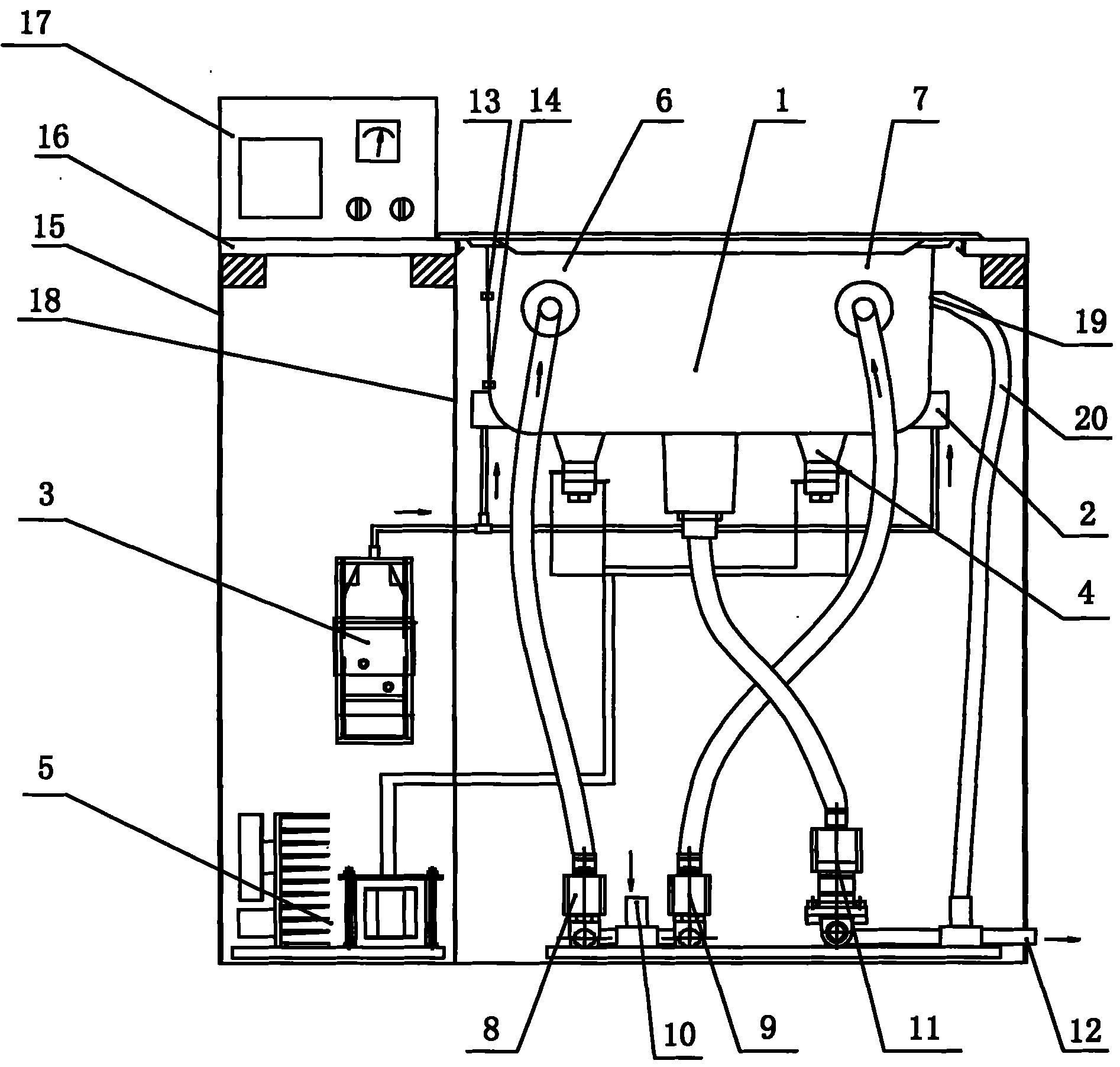

[0029] The structure of this embodiment is as figure 1 As shown, a kitchen ultrasonic ozone combined cleaning equipment includes a cleaning tank 1, an ozone distributor 2, an ozone generator 3, an ultrasonic transducer 4, an ultrasonic generator 5, a first nozzle 6, a second nozzle 7, a First water inlet solenoid valve 8, second water inlet solenoid valve 9, water inlet 10, water outlet solenoid valve 11, water outlet 12, high sensor 13, low sensor 14, cabinet body 15, table top 16, controller 17, water baffle 18, overflow port 19 and overflow pipe 20. Controller 17 is arranged on the table top 16 outside cabinet body 15, and other parts are arranged in cabinet body 15, and cleaning tank 1 and its parts below and ozone generator 3 and ultrasonic generator 5 are separated with water barrier 18.

[0030] The ultrasonic transducer 4 is arranged at the bottom of the cleaning tank 1 and is connected to the ultrasonic generator 5. The ultrasonic transducer 4 is provided with six, d...

Embodiment 2

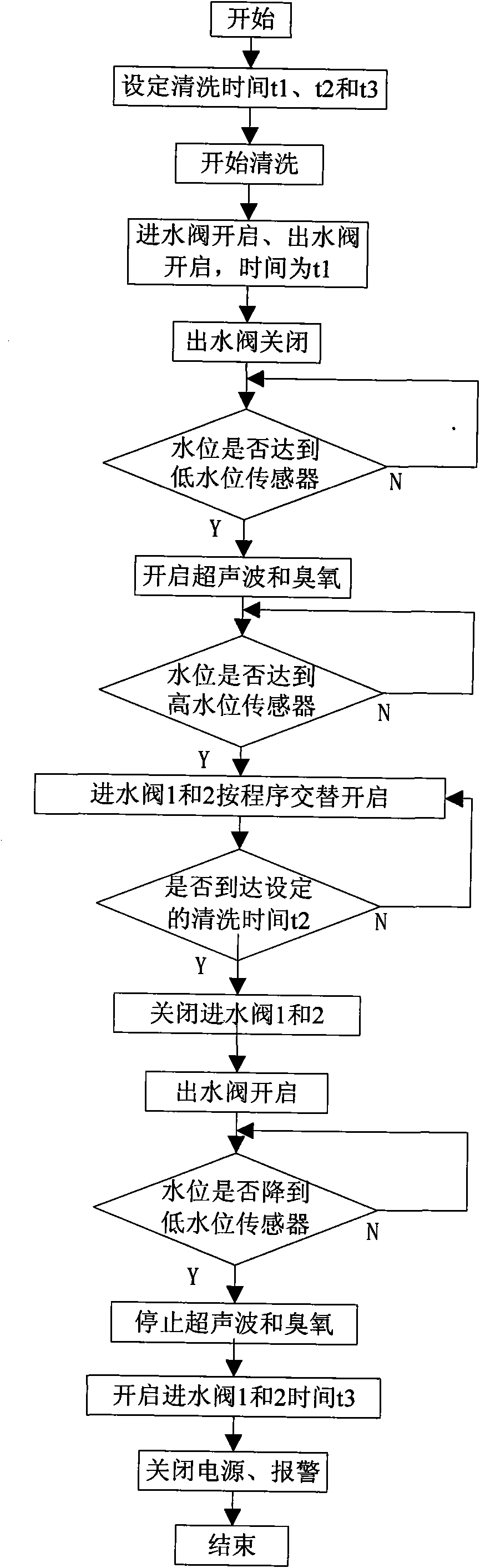

[0049] The kitchen ultrasonic ozone combined cleaning equipment of this embodiment is the same as that of Embodiment 1. The cleaning method of the kitchen ultrasonic ozone combined cleaning equipment of this embodiment: first, it is necessary to set the spray rinse time t1 as 40 seconds, and the ultrasonic ozone cleaning time t2 is 800 seconds and the secondary spraying time t3 is 50 seconds. After setting, the cleaning process is as follows:

[0050] The first step: spraying and rinsing; the first water inlet solenoid valve 8 and the second water inlet solenoid valve 9 are turned on, the water outlet solenoid valve 11 is turned on, and the impurities on the surface of the object to be cleaned are removed, and the ultrasonic generator 5 and ozone generator 3 are not turned on , with a duration of t1 (40 seconds).

[0051] Step 2: Ultrasonic ozone cleaning; close the outlet solenoid valve 11, start the ultrasonic generator 5 and ozone generator 3 when the liquid level reaches t...

Embodiment 3

[0055] The kitchen ultrasonic ozone combined cleaning equipment of this embodiment is the same as that of Embodiment 1. The cleaning method of the kitchen ultrasonic ozone combined cleaning equipment of this embodiment: first, it is necessary to set the spray rinse time t1 to 60 seconds, and the ultrasonic ozone cleaning time t2 is 900 seconds and the secondary spraying time t3 is 60 seconds. After setting, the cleaning process is as follows:

[0056] The first step: spraying and rinsing; the first water inlet solenoid valve 8 and the second water inlet solenoid valve 9 are turned on, the water outlet solenoid valve 11 is turned on, and the impurities on the surface of the object to be cleaned are removed, and the ultrasonic generator 5 and ozone generator 3 are not turned on , with a duration of t1 (60 seconds).

[0057] Step 2: Ultrasonic ozone cleaning; close the outlet solenoid valve 11, start the ultrasonic generator 5 and ozone generator 3 when the liquid level reaches t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com