Method for preparing organic solvent adsorbing material

A technology of adsorption materials and organic solvents, which is applied in the field of preparation of organic solvent adsorption materials, can solve the problems of no patents or public reports, and difficult removal of reactants, etc., to achieve thorough and uniform reaction, excellent organic solvent adsorption performance, and uniform silicon-aluminum ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A kind of preparation method of organic solvent adsorption material of the present invention, comprises the following steps:

[0033] a) Using molecular sieves with a diameter of 1-3 microns as raw materials to manufacture molecular sieve paper; the diameter of molecular sieves is selected at 1-3 microns because at this scale, the prepared slurry is easy to form a suspension, which is convenient for manufacturing into molecular sieve paper .

[0034] b) The molecular sieve paper obtained in step a) is hot-pressed into a corrugated shape.

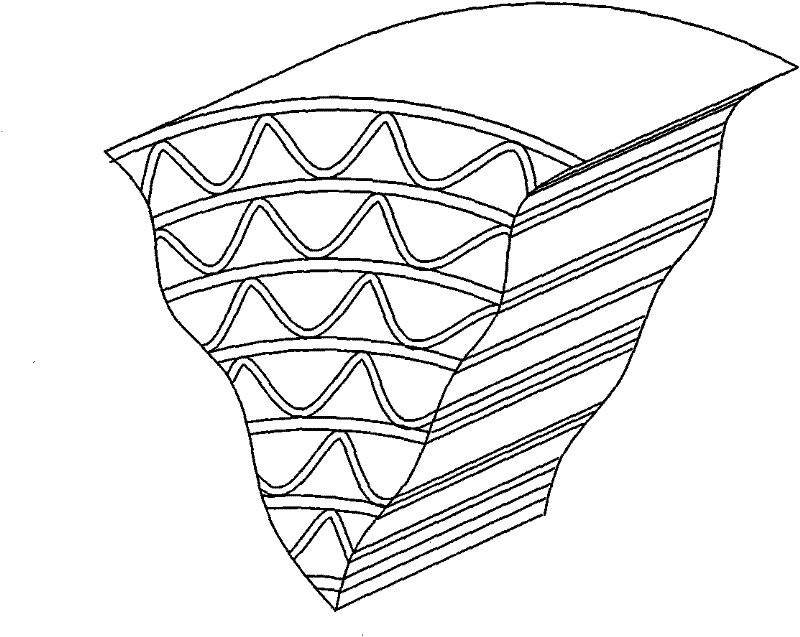

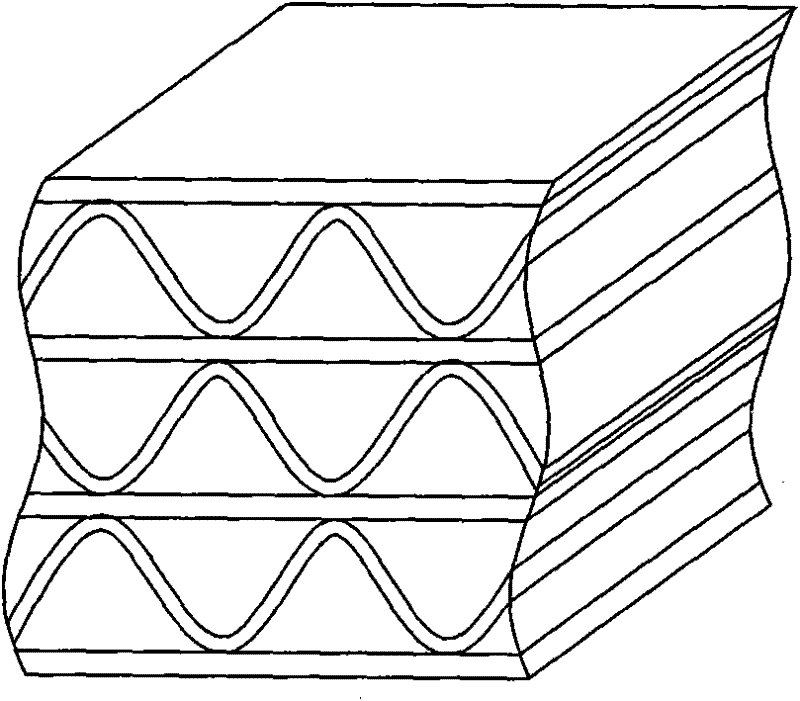

[0035] c) The corrugated molecular sieve paper obtained in step b) and the molecular sieve paper obtained in step a) are alternately stacked or rolled into a honeycomb body, and then baked.

[0036] d) Put the molecular sieve honeycomb body obtained in step c) into a closed container, and then pass nitrogen and SiCl at a temperature of 247°C-500°C into the container 4 The mixed gas of gas or water vapor at a temperature of 600°C-900...

Embodiment 1

[0043]a) Manufacture a Y-type zeolite molecular sieve with a diameter of 1 micron into molecular sieve paper by tape casting;

[0044] b), the Y-type zeolite molecular sieve paper obtained in step a) is hot-pressed into a corrugated shape;

[0045] c) The corrugated Y-type zeolite molecular sieve paper obtained in step b) and the Y-type zeolite molecular sieve paper obtained in step a) are alternately stacked or rolled into such a figure 1 , figure 2 The honeycomb body shown, and then baked;

[0046] d) Place the honeycomb body obtained in step c) into a closed container, and then pass nitrogen and SiCl at a temperature of 247°C into the container 4 Gas mixture, which will chemically react with the molecular sieve on the molecular sieve honeycomb;

[0047] e) After maintaining step d) for 4 hours, stop passing the reaction gas into the container, and pass nitrogen gas at a temperature of 80°C into the container to discharge the remaining reaction gas in the container;

[...

Embodiment 2

[0051] a) Manufacturing a BETA molecular sieve with a diameter of 3 microns into molecular sieve paper by coating method;

[0052] b), the molecular sieve paper obtained in step a) is hot-pressed into a corrugated shape;

[0053] c), the corrugated molecular sieve paper obtained in step b) and the molecular sieve paper obtained in step a) are alternately stacked or rolled into a shape such as figure 1 , figure 2 The honeycomb body shown, and then baked;

[0054] d) Put the honeycomb body obtained in step c) into a closed container, heat the honeycomb body to 600°C, and then pass water vapor at a temperature of 600°C into the container, which will combine with the molecular sieve on the molecular sieve honeycomb body A chemical reaction occurred;

[0055] e) After maintaining step d) for 6 hours, stop passing the reaction gas into the container, and pass nitrogen gas at a temperature of 100°C into the container to discharge the remaining reaction gas in the container, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com