Overprinting stamp and manufacturing method thereof

A production method and seal technology, applied in printing, printing devices, stamping, etc., can solve the problems of complex results and inability to achieve the effect of color harmony, and achieve a healthier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with accompanying drawing.

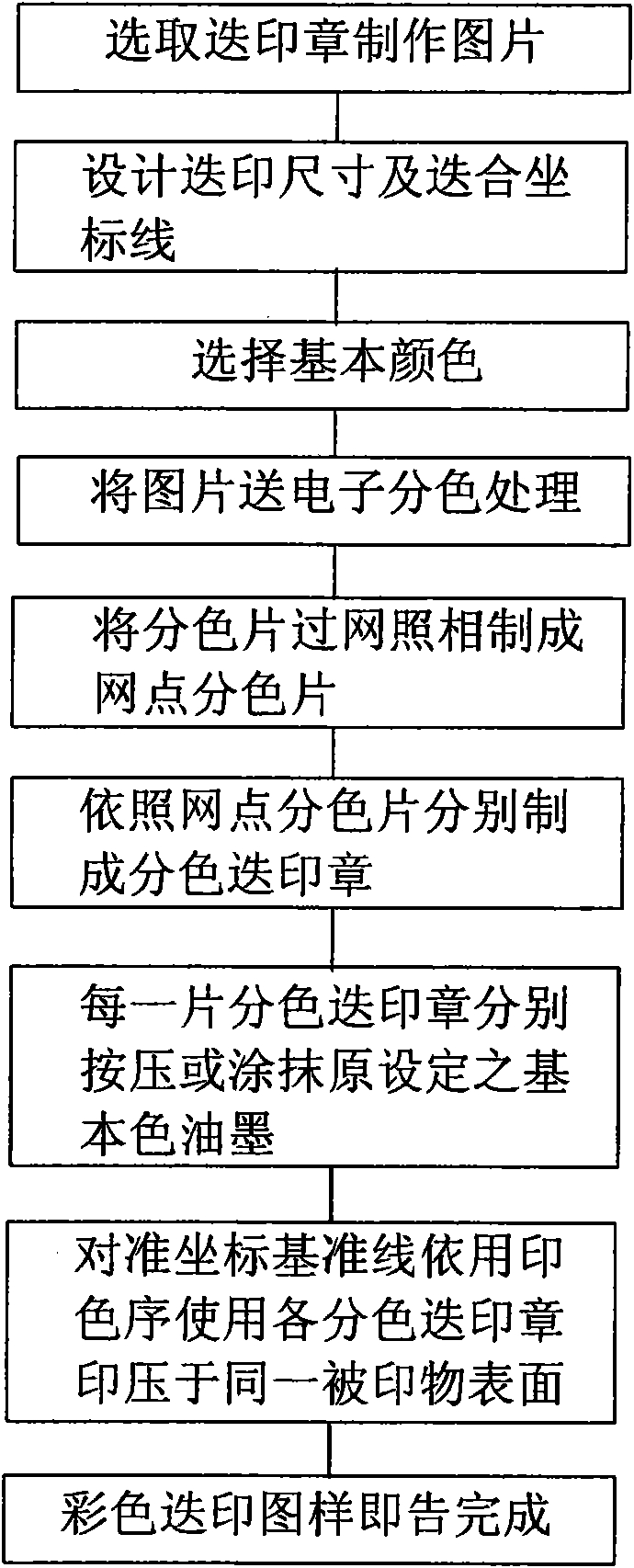

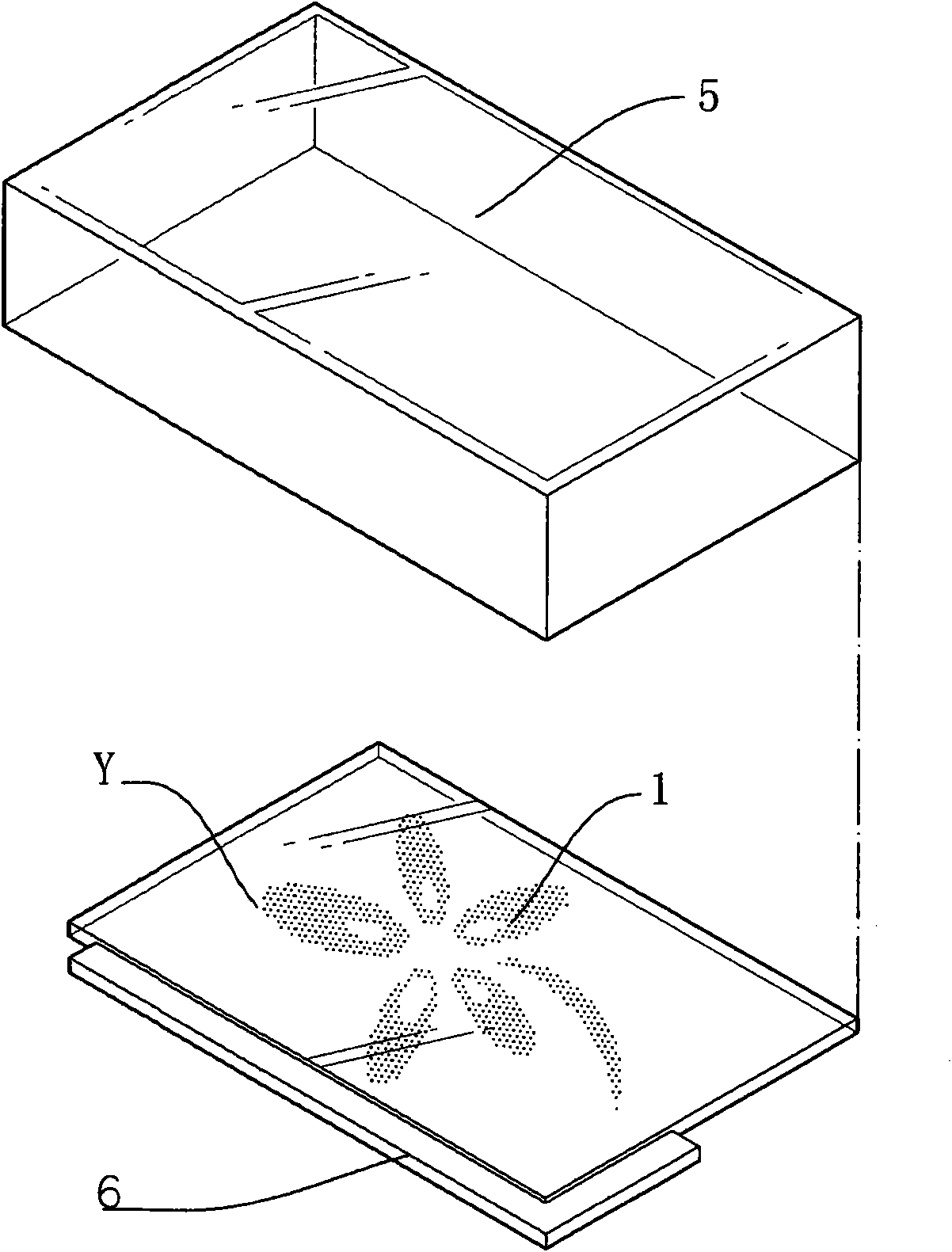

[0065] figure 1 It is the production flow chart of the present invention using network dots to produce overlapping stamps. Surfaces of any color can be made into overstamps, and overstamps of certain colors can be selected. After the basic color of the stamp surface and stacked stamps is selected, many stamp materials are transparent and have the characteristics of perspective; for opaque stamps, as long as each stacked color stamp has the same shape and size, it can be positioned It is very convenient to overprint by using the reference line, ruler board or outer frame line.

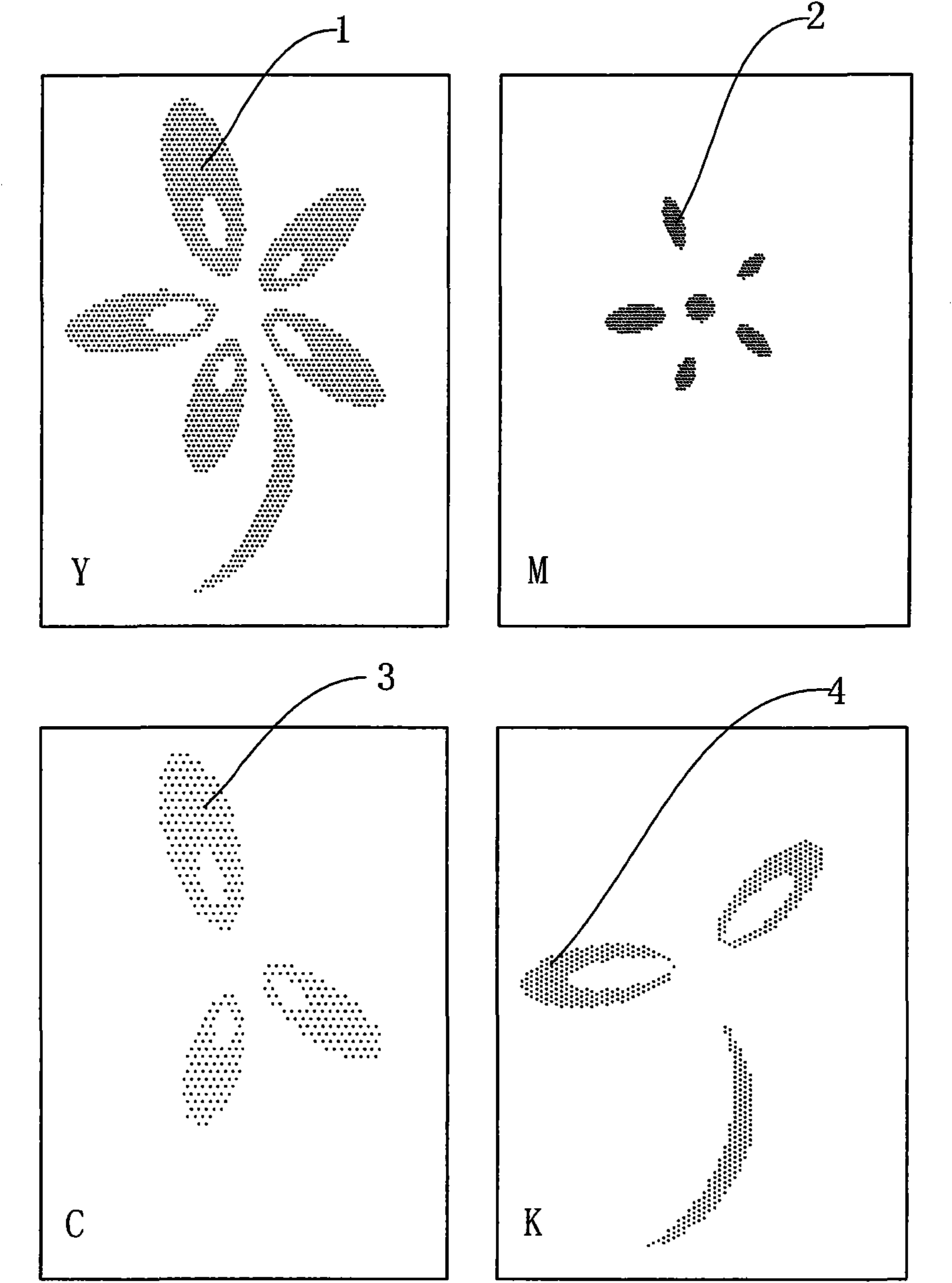

[0066] The most important task of the present invention is to make the electronic color separation and screen photography of the drawing surface into the color separation sheet drawing surface of different colors stacking stamps, and then use the traditional stamp making technology to make differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com