Automobile body structure

A car body and body technology, applied in the substructure, tractor-trailer combination, motor vehicles, etc., can solve the problems of poor load sharing capacity, constraints, off-road performance, and limited height of passing load, etc., to achieve increased load Ability, improved passability, and reasonable position effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

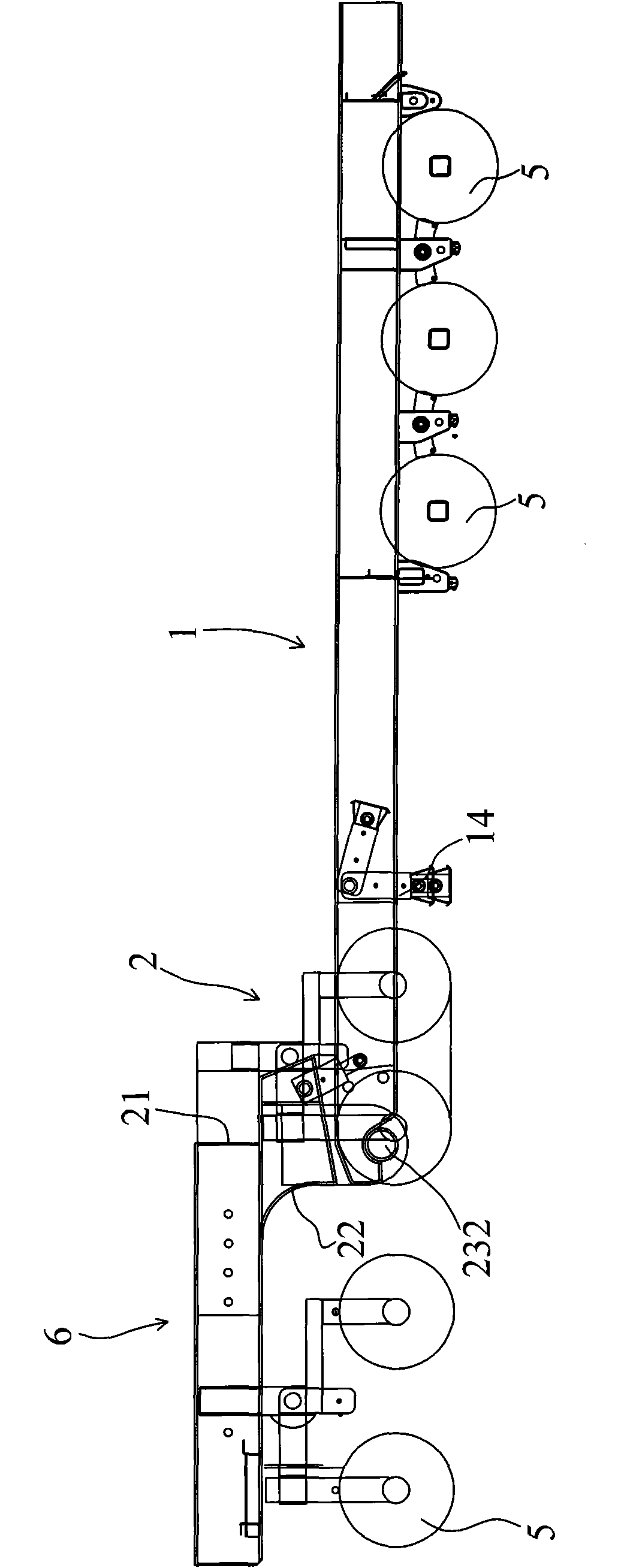

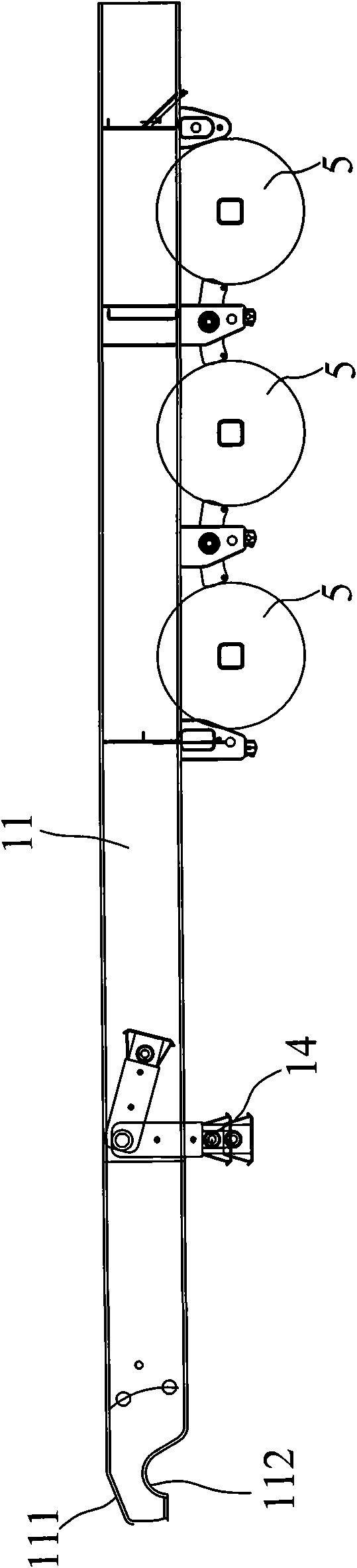

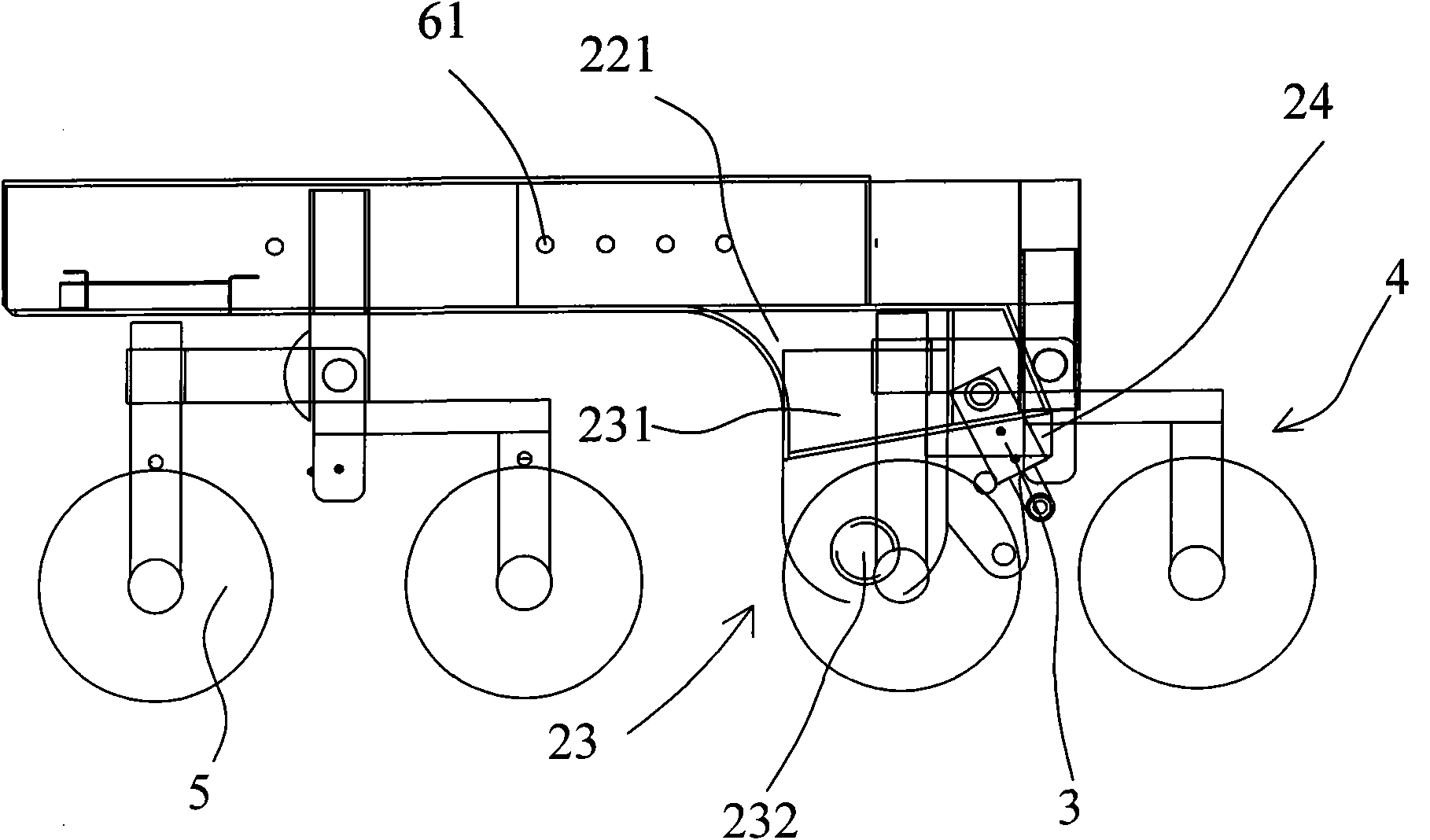

[0015] Please refer to Figure 1 to Figure 3 , which is a preferred embodiment of the present invention, the automobile body structure includes a front body 6 and a rear body 1 that are articulated together by a hinge device 2 and supported by a wheel train 5 respectively. The hinge seat at the lower part of the tail end of the front body 6 is connected to two hinge mechanisms 23 on both sides of the hinge seat respectively, and the hinge shaft 232 at the bottom of the hinge mechanism 23 is connected to the front both sides of the rear body 1. Hinged so that the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com