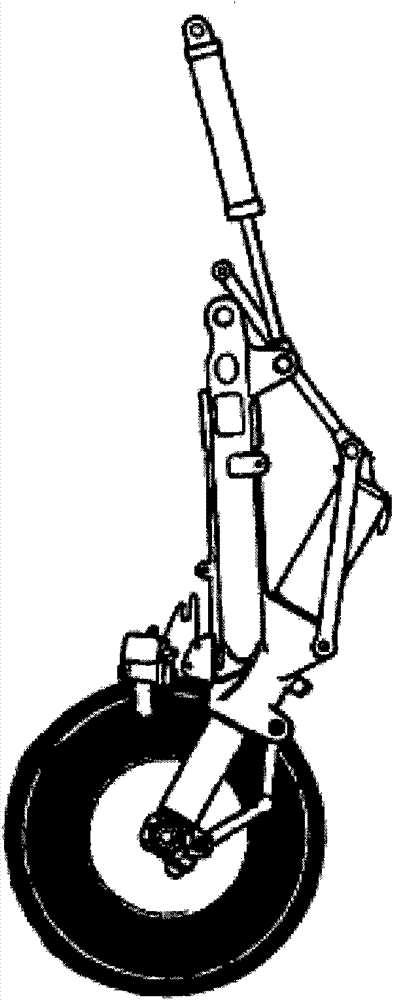

Aircraft landing gear

A technology of aircraft landing gear and lugs, applied in the field of aircraft landing gear, can solve the problems of inability to retract and retract, and achieve the effect of uniform force and good force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

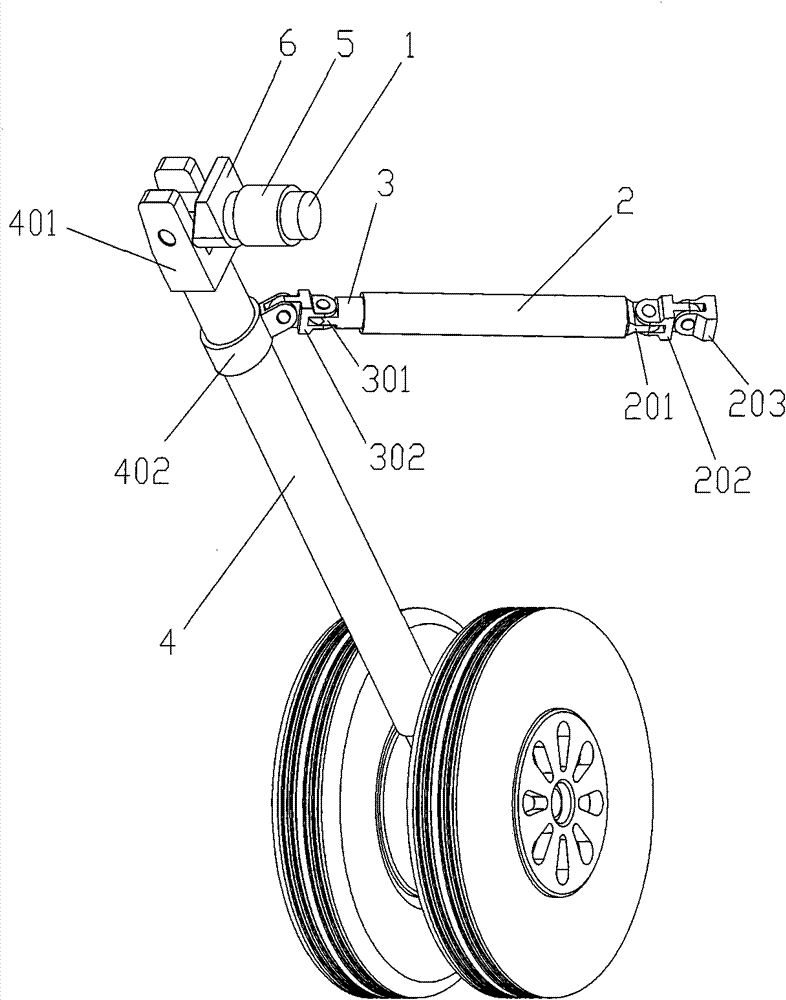

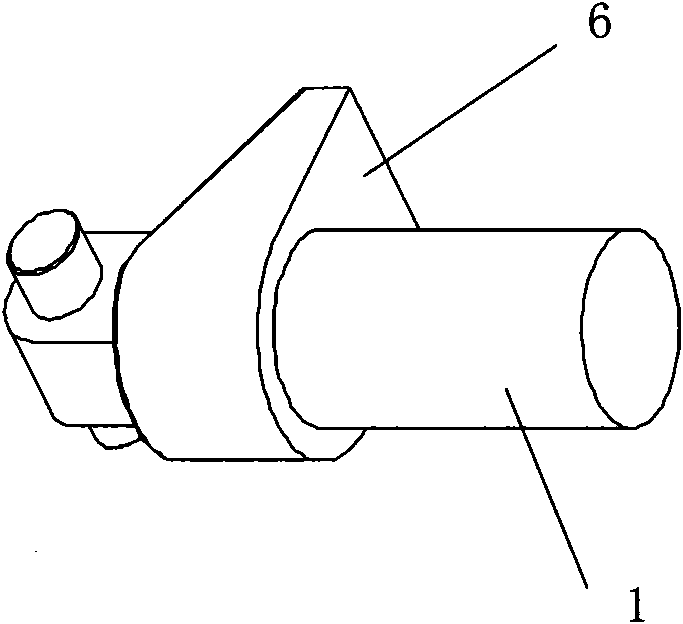

[0018] Such as figure 2 As shown, an aircraft landing gear of the present invention includes a rotating shaft 1 , an actuator 2 , a buffer 4 , a sleeve 5 , a shoulder 6 and two cross-shaped hinged lugs 202 , 302 . Sleeve 5 is fixedly connected on the fuselage. The rotating shaft 1 is located in the sleeve 5, and it is connected with the locking device. The locking control mode of the locking control device may be a common locking control mode in aircraft landing gear, such as an up lock and a down lock in the landing gear. When the locking device locks the rotating shaft 1, the rotating shaft 1 cannot rotate in the sleeve 5; when the locking device unlocks the rotating shaft 1, the rotating shaft 1 can rotate in the sleeve 5. The top end of the buffer 4 is provided with a first lug 401 , and the middle is provided with a second lug 402 . The rotating shaft 1 is embedded in the first lug 4 , and there is a gap between the first lug 4 and the rotating shaft 1 . The rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com