High-transparency thick polyester film

A polyester film, transparent technology, applied in the field of polyester film, can solve the problems of increasing the turbidity of polyester film, increasing the degree of fogging of polyester film, and destroying the transparency of polyester film, achieving high transparency and good chemical resistance , the effect of good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

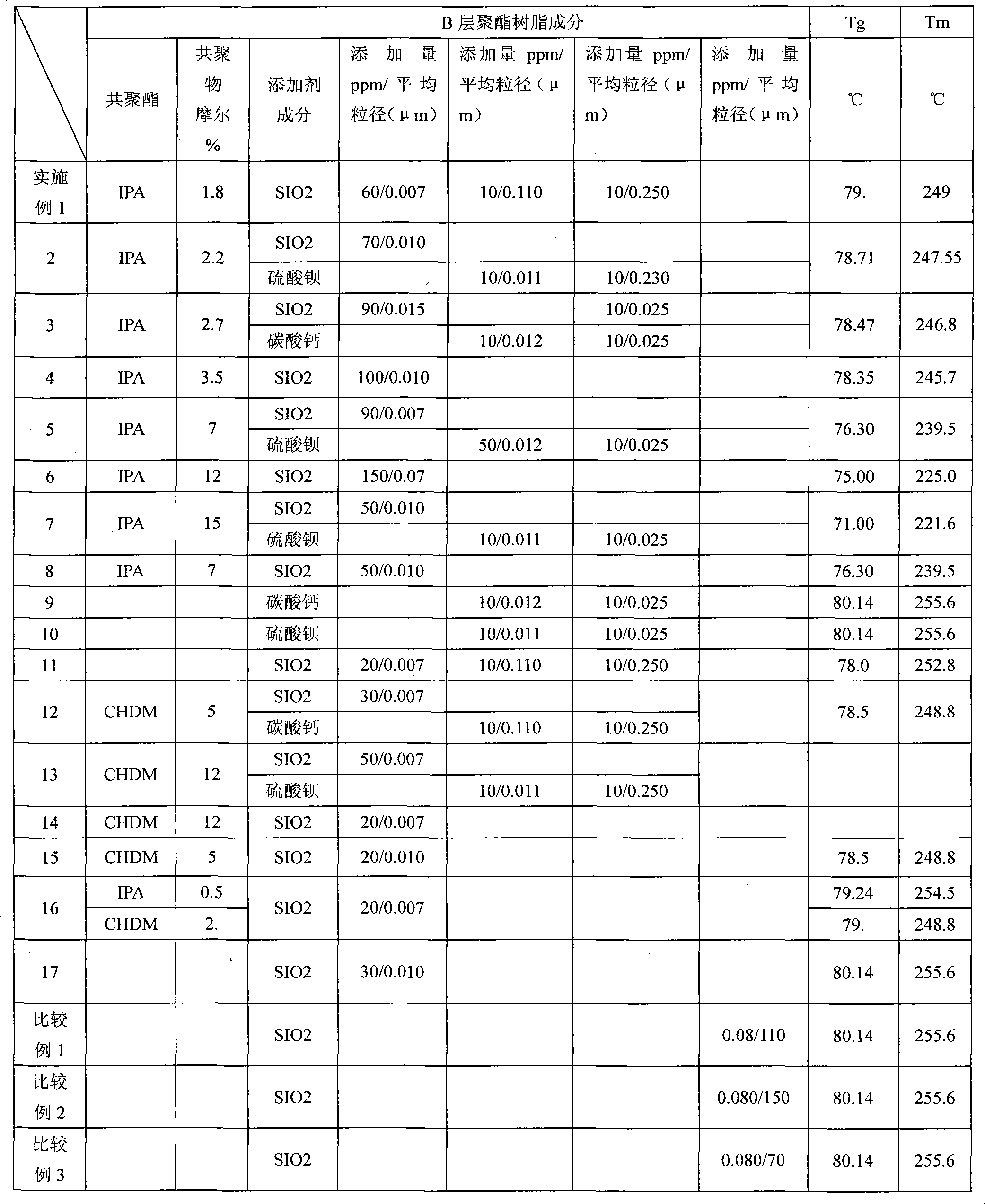

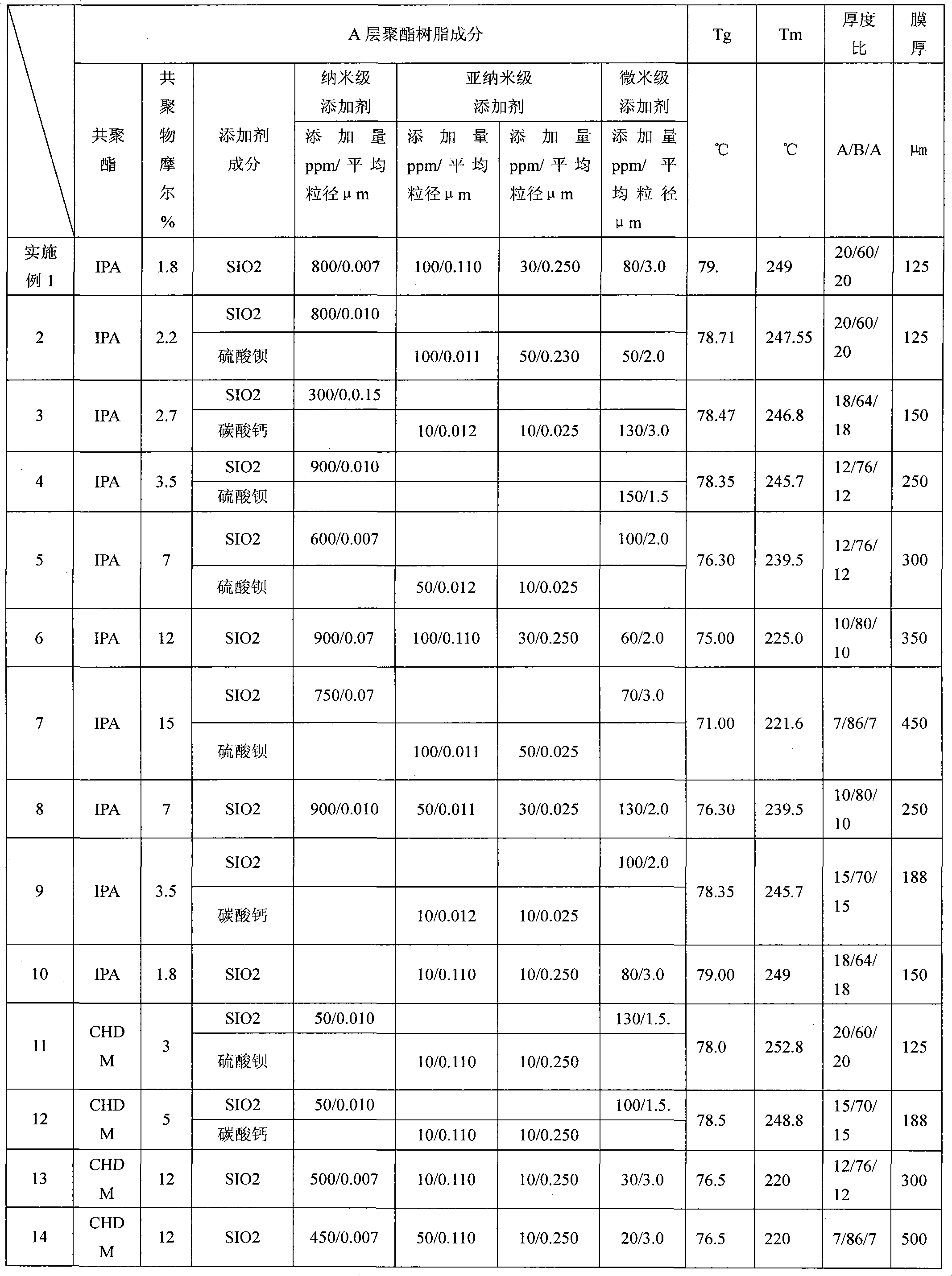

[0034] The copolyester containing 1.8% isophthalic acid (accounting for the molar content of the acid in the synthesis) and the polyester masterbatch with an average particle size of 0.007 μm as a silicon dioxide slip agent are chipped, and the average particle size is 0.110 μm. The polyester masterbatch slices and the silica polyester masterbatch slices with an average particle size of 0.250 μm are uniformly mixed, and finally the content of the average particle size of 0.007 μm silica in the total polyester chips is 60PPm, and the average particle size The content of 0.110 μm silica in the total polyester chips is 10PPm, and the average particle size of 0.250 μm silica in the total polyester chips is 10PPm. After mixing these four raw materials, the raw materials used as the core layer (layer B) were crystallized and dried at 160°C, and then the materials were fed into a single-screw extruder for melt extrusion at 275°C.

[0035] The copolyester containing 1.8% isophthalic a...

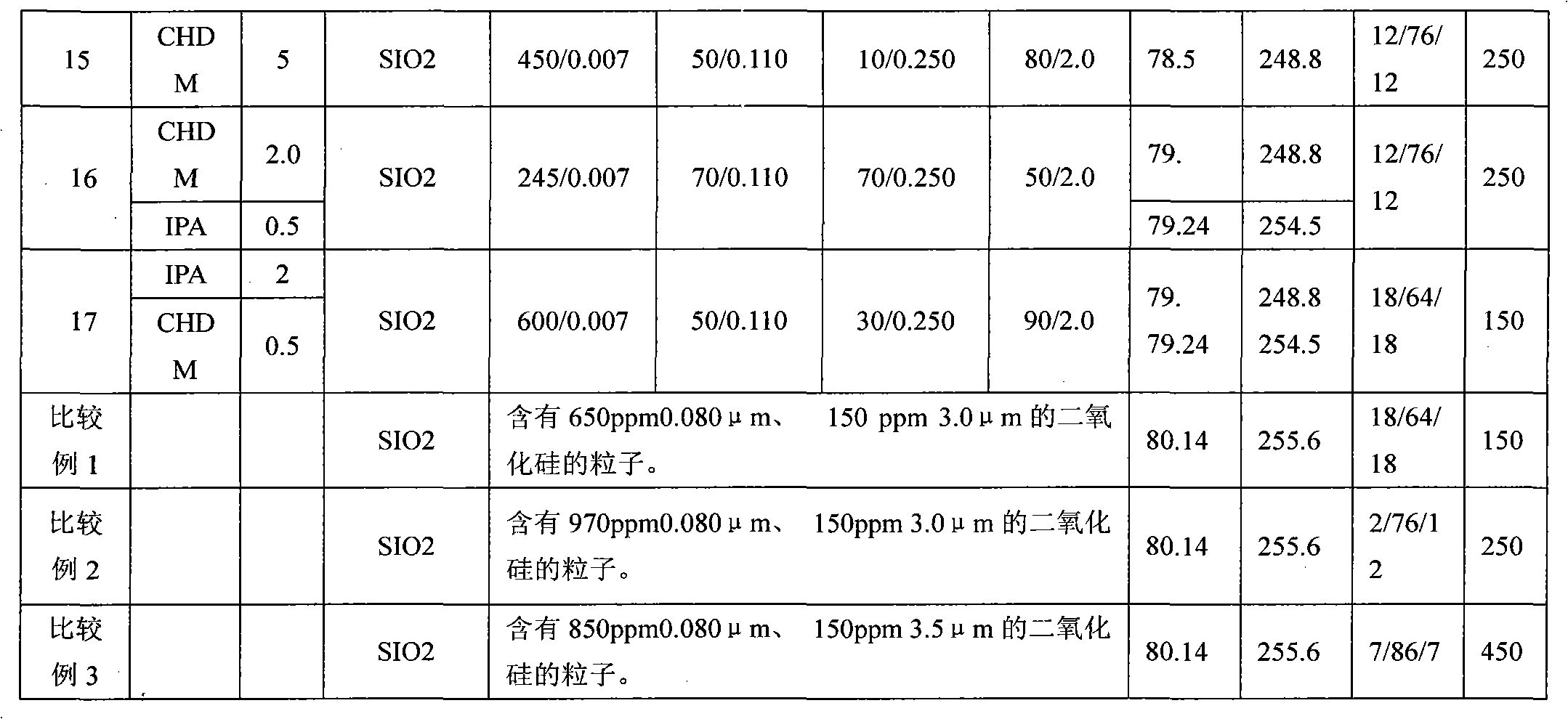

Embodiment 2~15

[0039] With the preparation method similar to Example 1, according to the layer structure and thickness ratio of the film described in Table 1, the composition of A and B polyester components, the composition, particle size and content of the additives, thick-type high-quality films with different thicknesses were prepared. Clear polyester film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com