Bridge girder erection machine capable of passing through tunnel and realizing girder erection and bridging process thereof

A bridge erecting machine and tunnel technology, which is applied in the field of new bridge erecting machines for passing tunnels and tunnel opening beams, can solve the problems of low construction efficiency, high stability of guide beams, unable to complete the opening beam erection, etc., and achieve stable operation, The effect of high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

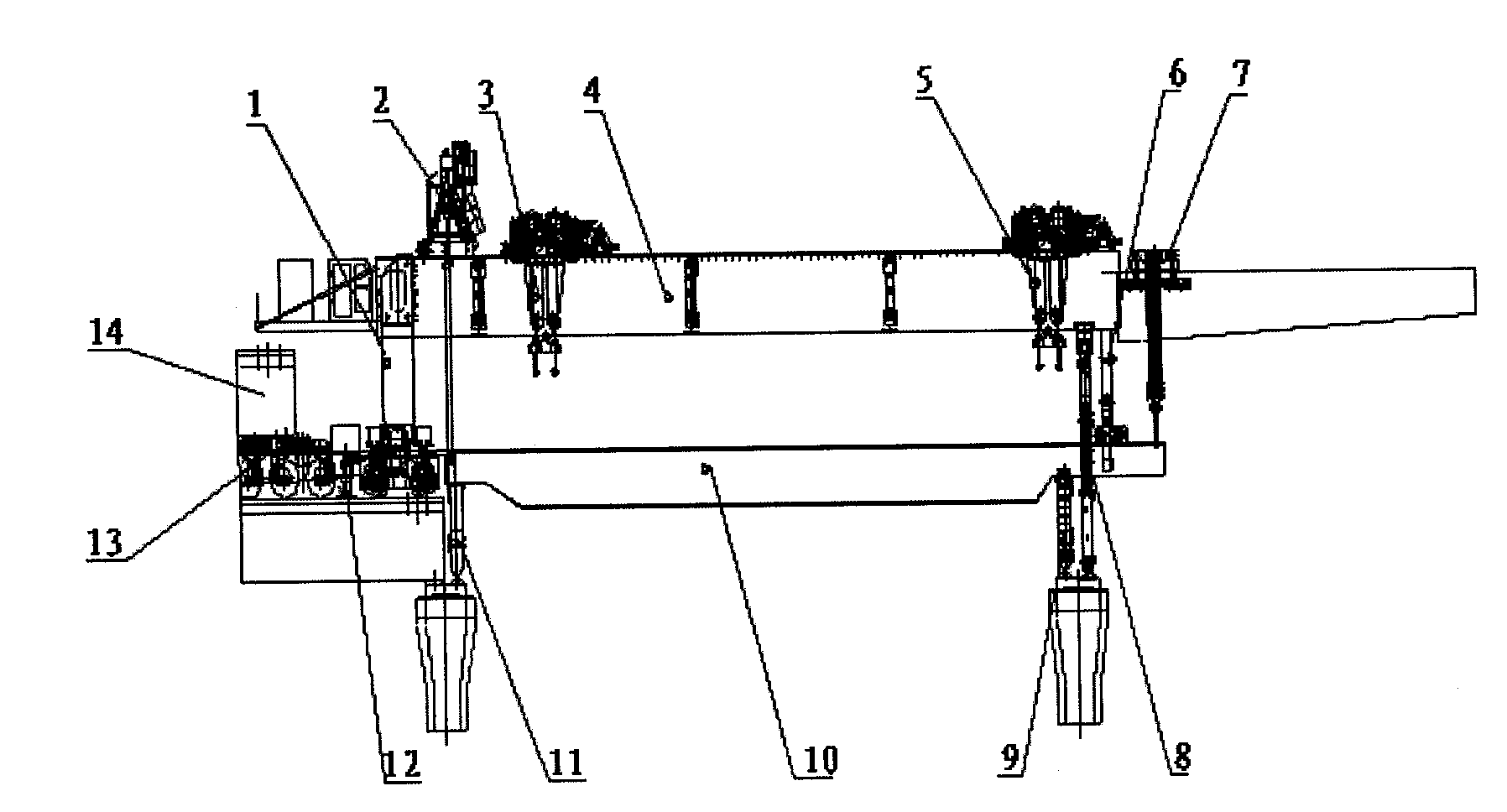

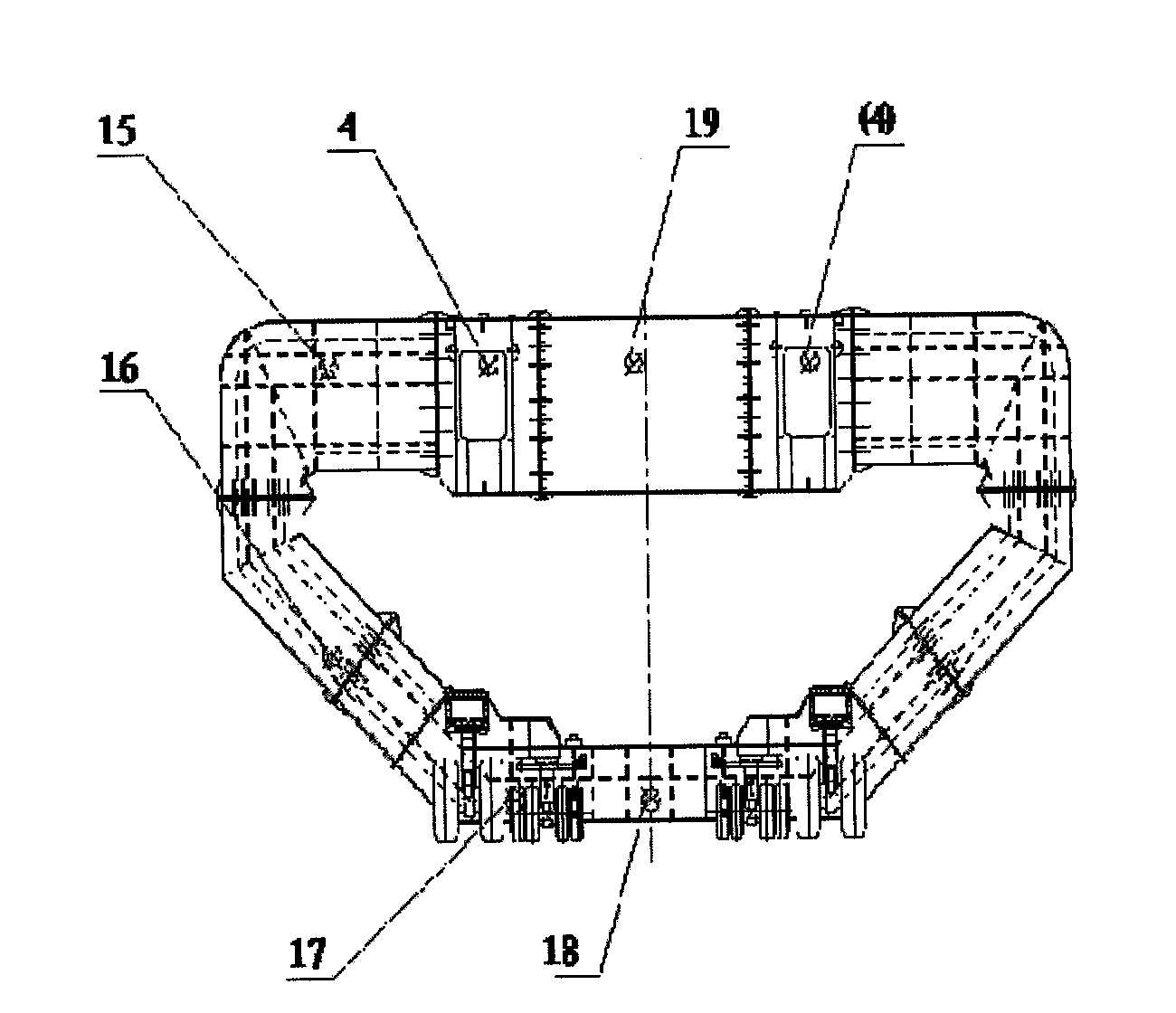

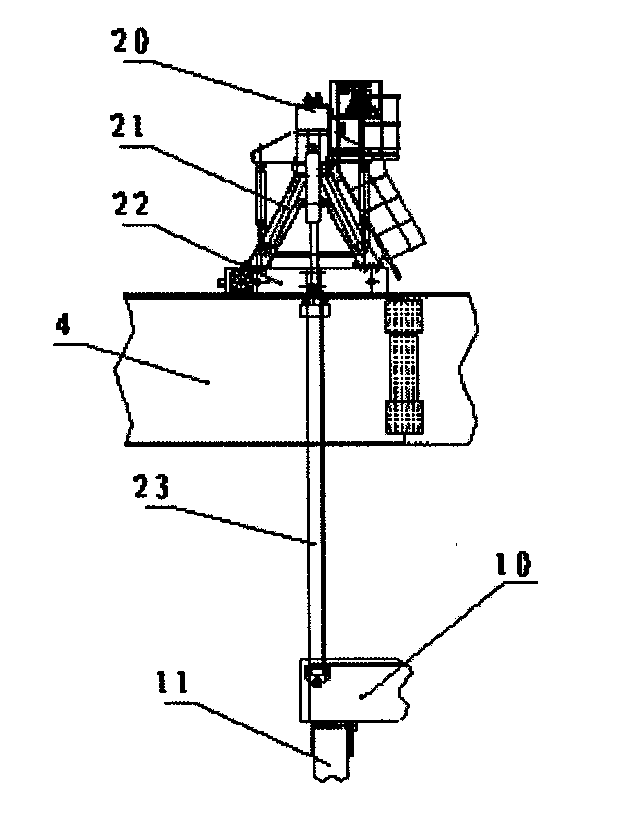

[0050] refer to figure 1 According to the present invention, the bridge erecting machine capable of passing through a tunnel and realizing beam erection at the tunnel entrance mainly includes a main engine and a lower guide beam 10 . Described main engine comprises main beam 4 and from the back end of main beam 4 to the front end (so-called front and back is that the beam erecting direction is the front, vice versa) is installed with rear outrigger 1, rear guide beam crane 2, rear lifting Heavy trolley 3, front hoisting trolley 5, front outrigger 8, auxiliary walking outrigger 6, leading beam crane 7. A track is arranged on the main girder 4, and the front lifting trolley 5, the rear lifting trolley 6, the front guide beam crane 7 and the rear guide beam crane 2 run on the track. The lower guide beam 10 includes the main beam of the lower guide beam, the rear outrigger 11 located at the rear and lower side thereof, and the front outrigger 9 located at the front lower side. D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com