H-shaped shaft flood discharge hole

A technology of flood tunnels and shafts, which is applied in the field of flood tunnels, can solve problems such as unstable water flow transitions, prone to hydraulic jumps in flood tunnels, and affecting the safe operation of flood tunnels, so as to ensure safe operation, realize water flow, and safe connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The water retaining structure of a water conservancy project adopts a concrete gravity dam, the maximum dam height is 210m, and the discharge capacity of the spillway tunnel is 1350m 3 / s, has the characteristics of narrow river valley, high water head, large flow and high velocity.

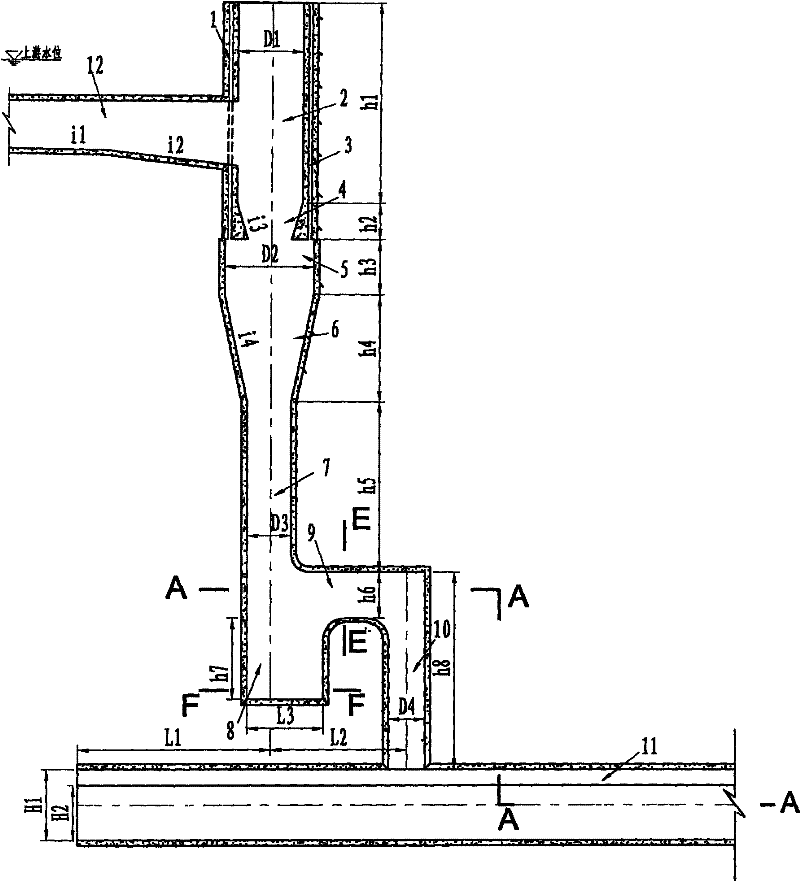

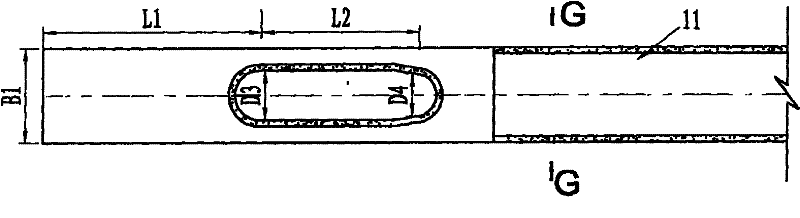

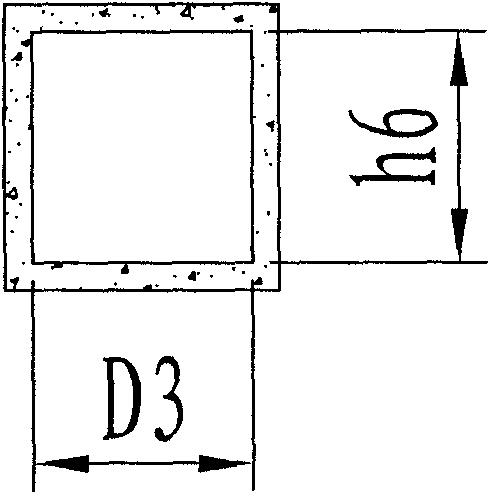

[0022] In this embodiment, the structure of the h-shape shaft spillway is as follows figure 1 , figure 2 As shown, it consists of a "city gate hole" shaped flood discharge tunnel 11 and a shaft connected to the flood discharge tunnel arranged at the closed end of the flood discharge tunnel. The shaft includes a first shaft 1 and a second shaft 10; the first shaft 1 is double The vortex-chamber air-mixed swirl shaft is located above the spillway, and its centerline intersects vertically with the centerline of the spillway, its upper part is connected to the water flow diversion channel 12, and its lower end is closed; The centerlines are parallel, the upper end is closed, and the lower e...

Embodiment 2

[0036] The water retaining structure of a water conservancy project adopts a concrete gravity dam, the maximum dam height is 180m, and the discharge capacity of the spillway tunnel is 570m 3 / s, has the characteristics of narrow river valley, high water head, large flow and high velocity.

[0037] In this embodiment, the structure of the swirl shaft submerged flood discharge tunnel is the same as that in Embodiment 1, as figure 1 , figure 2 Shown, difference with embodiment 1 is the size of each part, relevant size is as follows:

[0038] The relevant dimensions are as follows:

[0039] 1. Lead the canal

[0040] The slope i1 of the water inlet section I = 1:22, and the slope i2 of the water inlet section II of the diversion channel = 1:12.

[0041] 2. The first shaft - double vortex chamber aeration type swirl shaft

[0042] The diameter of the upper vortex chamber D1=10m, the height of the upper vortex chamber h1=40m, the height of the contraction section of the upper vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com