Prefabricated reinforced concrete unit body for construction and method for building construction

A technology of reinforced concrete and unit body, which is applied to the processing of building components, building structures, and building materials. It can solve the problems of low mechanization application, single structural force, and high operating risk, so as to reduce personal safety risks, The effect of reducing abandoned construction waste and clear division of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

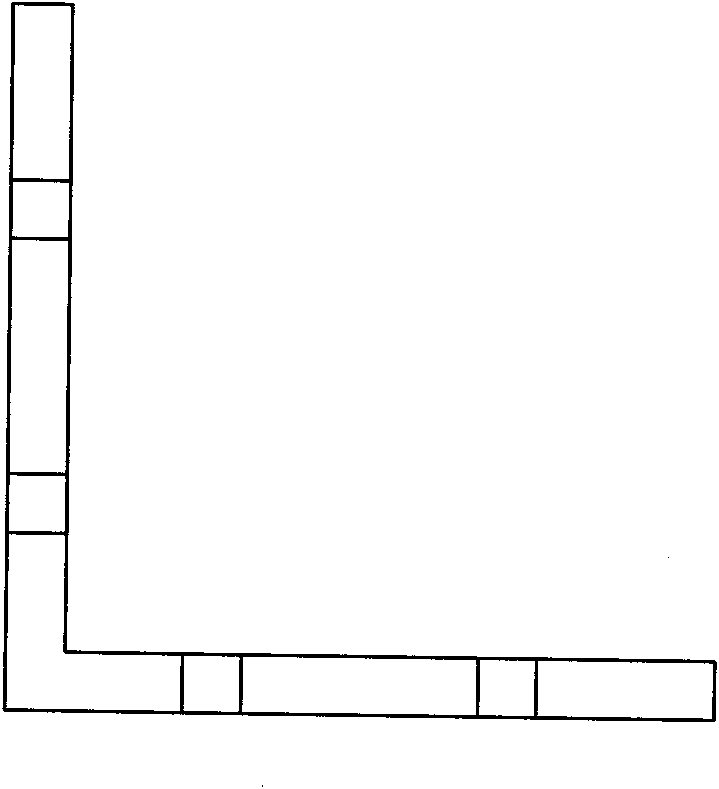

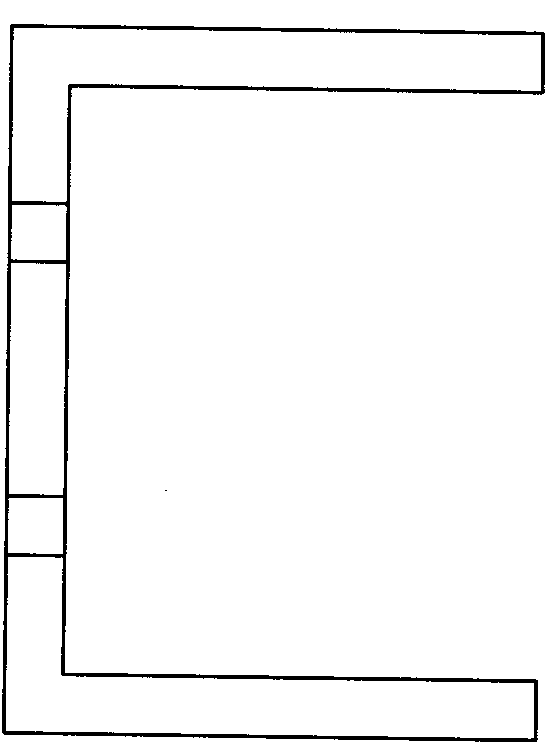

[0046] A prefabricated reinforced concrete unit body for building, as attached Figures 1 to 7 As shown, the prefabricated reinforced concrete unit body is an integral unit body composed of a bottom plate, a wall / column body, and an upper floor slab, and the bottom plate, wall / column body, and upper floor slab of the prefabricated reinforced concrete unit body are provided with anchors for positioning And draw and connect reinforcing bar, its inside draws and connects criss-cross floor double-layer reinforcing bar 6 or wall body double-layer reinforcing bar 7. The tie piece includes a corner piece 1 , a groove piece 3 and a vertical piece 4 . The corner piece 1 is arranged along the edge of the upper and lower panels of the prefabricated reinforced concrete unit body; the channel piece 3 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com