Gas-liquid cooling device

A cooling device, gas-liquid technology, applied in the direction of water shower coolers, heat exchange equipment, direct contact heat exchangers, etc., can solve the problems of insufficient contact, neutralization of acid and alkali, and unsatisfactory purification effects, etc., to achieve avoid runny effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

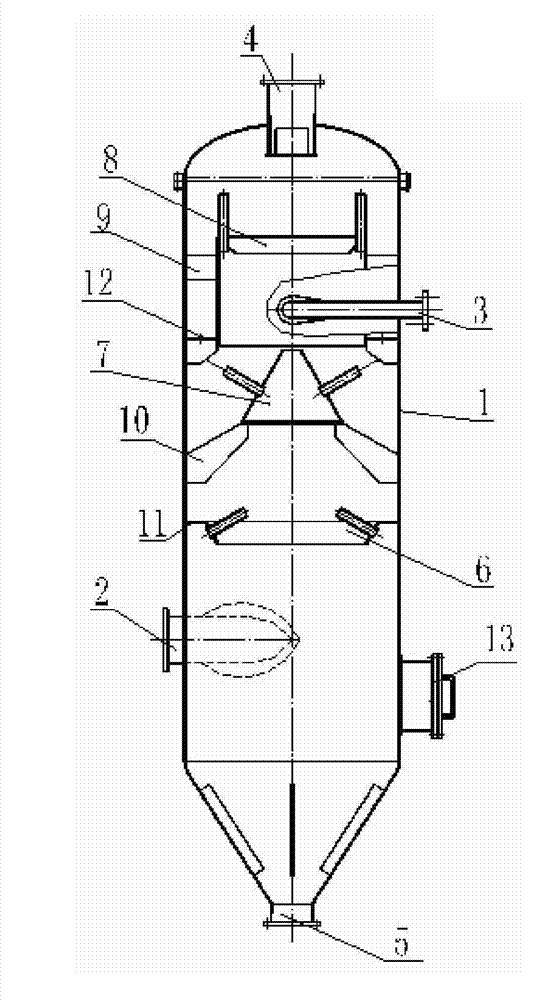

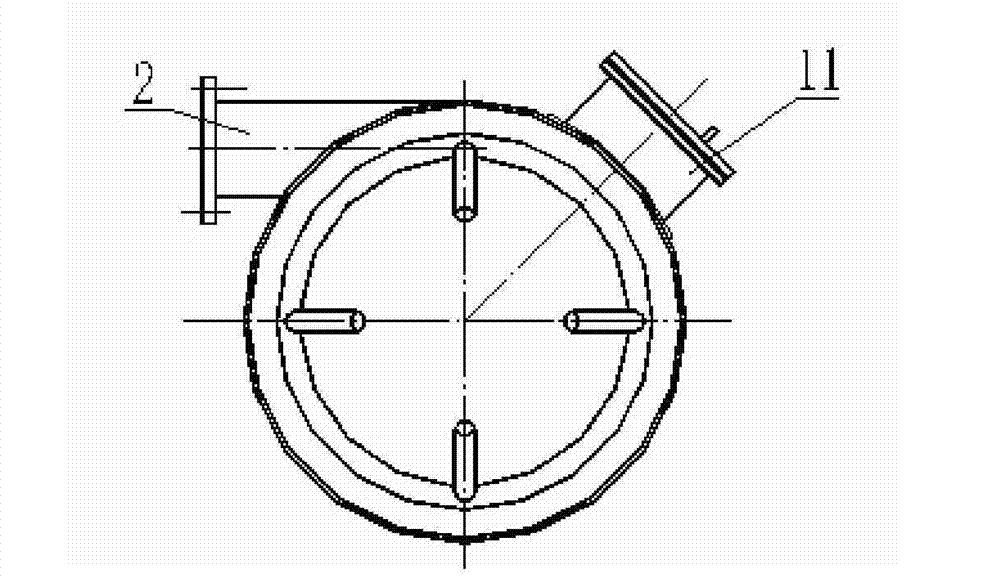

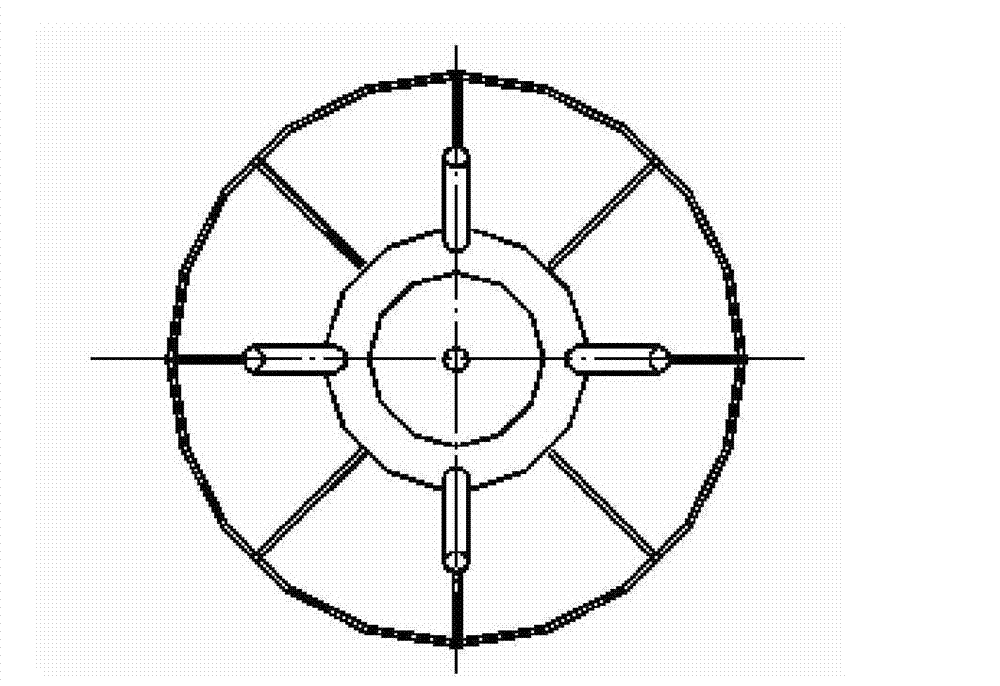

[0016] Embodiment 1 of the present invention: as figure 1 As shown, the gas inlet 2 tangent to the cylinder body is welded at the lower end of the tower body 1, the gas outlet 4 is welded at the uppermost end of the tower body 1, the liquid outlet 5 is welded at the lower end, and a layer of gas is arranged on the gas inlet 2 Distributor 6, the structure of one layer of gas distributor 6 is as figure 2 Shown is a conical tube with a large mouth facing upwards, and a pipe is obliquely inserted on the surface of the conical tube, which is welded and fixed on the inner wall of the tower body 1 through the ring plate 11, and the second-layer gas distributor 7 is set on the first-layer gas distributor 6 , The structure of the two-layer gas distributor 7 is as follows: image 3 Shown is a conical tube with a small mouth facing upwards, a pipe is obliquely inserted on the surface of the conical tube, a circular plate is covered at the small opening of the conical tube, a small hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com