Unit for filling containers, comprising an insulator, especially for a production installation

A technology for production equipment and isolators, applied in packaging, packaging sterilization, packaging protection, etc., can solve problems such as not being completely satisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following description and claims, terms such as "upper" and "lower", "axial" and "radial" are used by way of example and not limitation, and longitudinal, vertical The directional and transverse orientations are used to indicate elements respectively according to the definitions given in the description and with respect to the trihedron (L, V, T) shown on the diagram.

[0033] In the description, identical, similar or like elements are indicated by the same reference numerals.

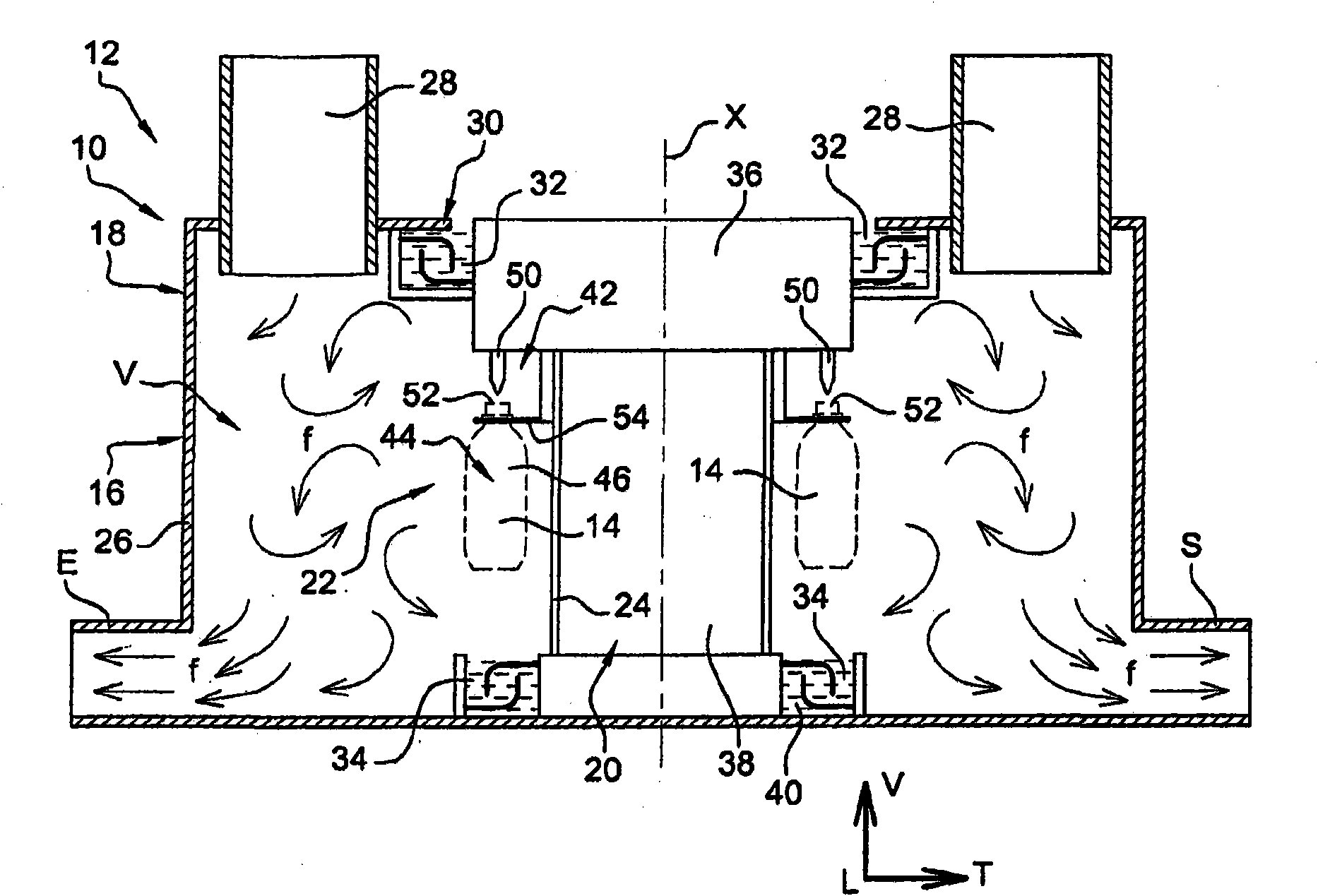

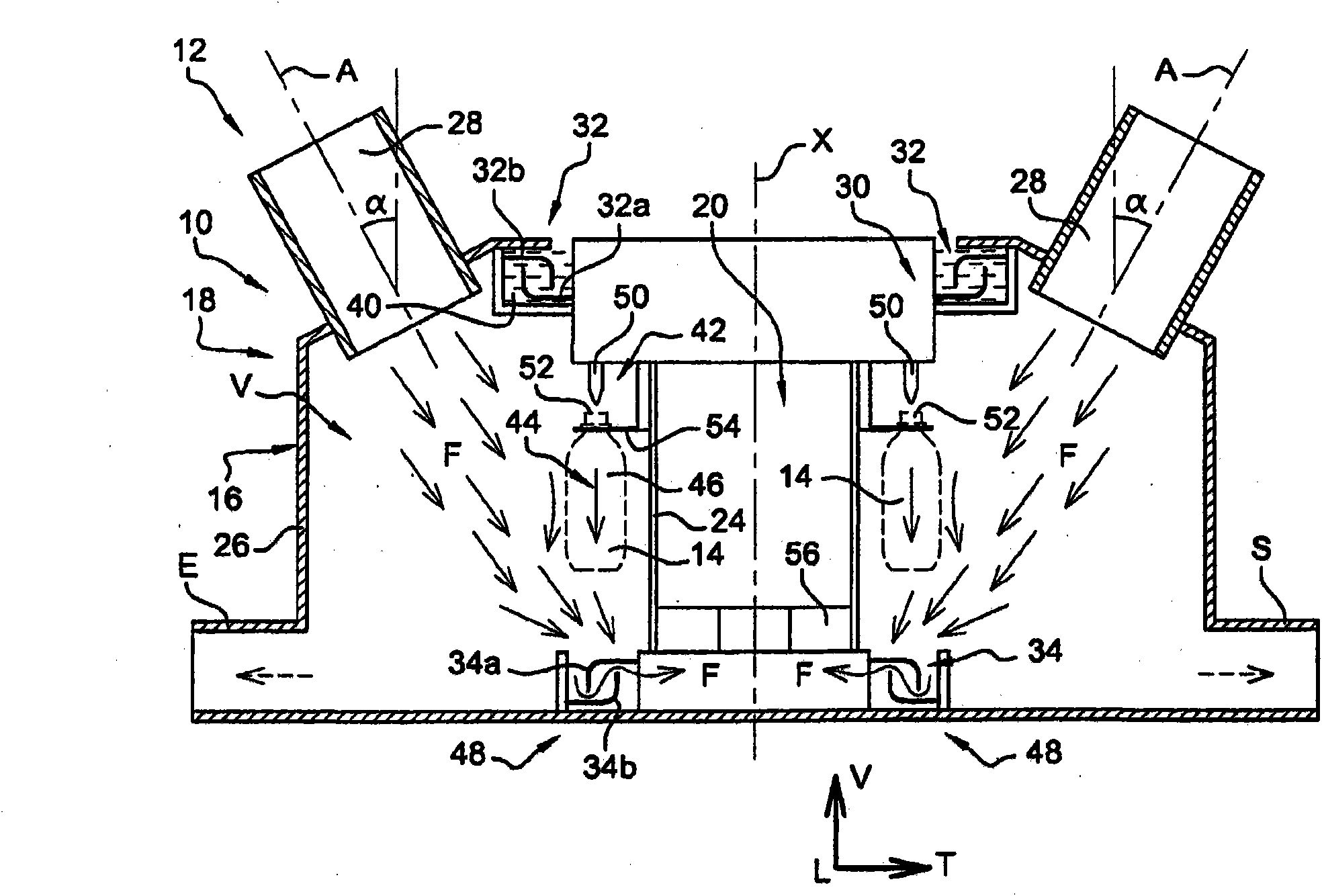

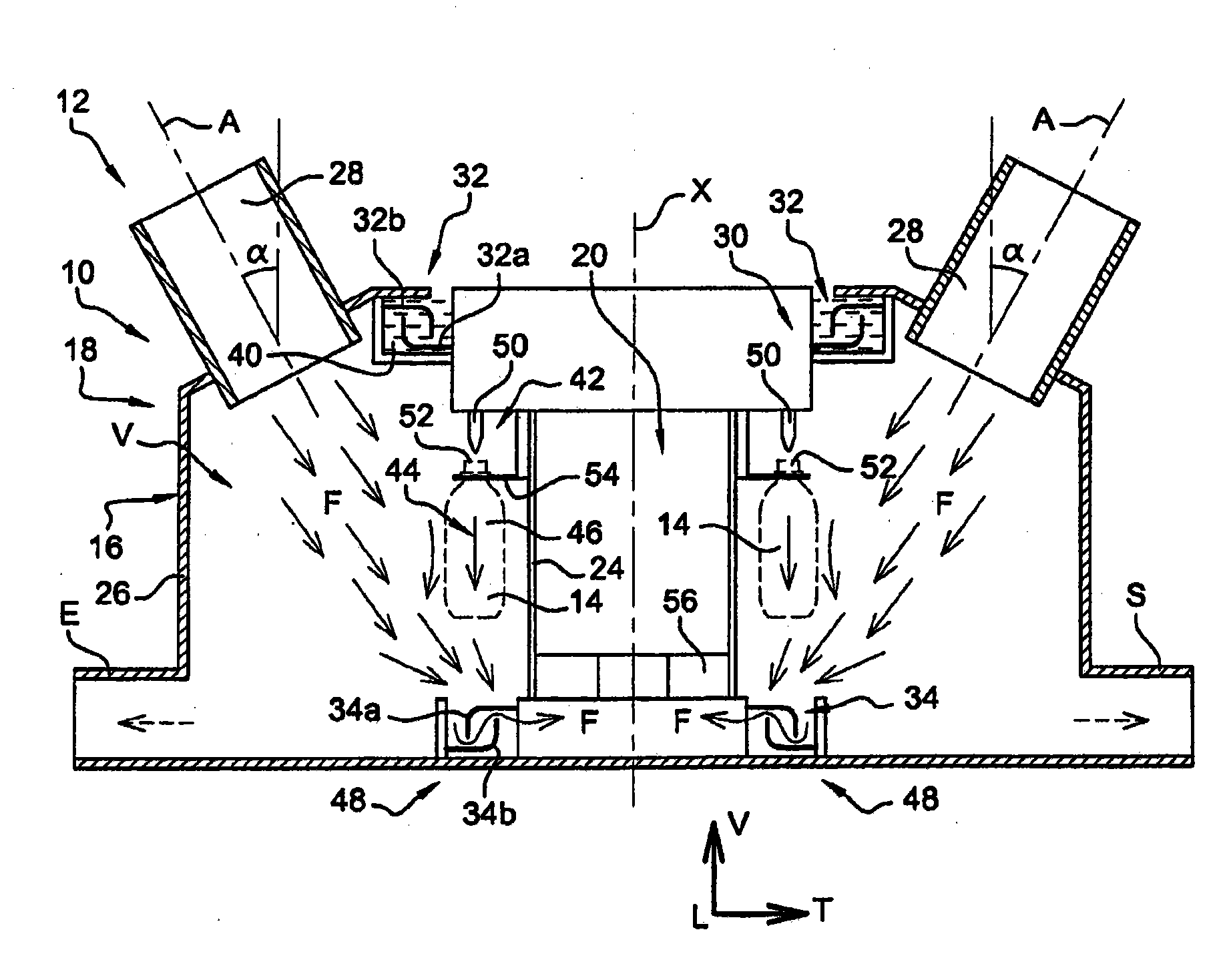

[0034] In order to illustrate the present invention, in figure 1 A filling unit 10 according to the prior art is shown above, which can be integrated, in particular, into a container production plant 12 .

[0035] In what follows in the present description, the term "container" designates generally and non-limitatively all types of containers 14, such as bottles, ampoules and the like.

[0036] The container filling unit 10 comprises an isolator 16 in order to carry out the container fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com