Installation structure of underground air cannon

A technology of installation structure and air cannon, which is applied in the direction of packaging, transportation and packaging, containers, etc., can solve the problems of difficult cleaning, danger, uneven feeding, etc., and achieves easy popularization and application, good anti-arching effect, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

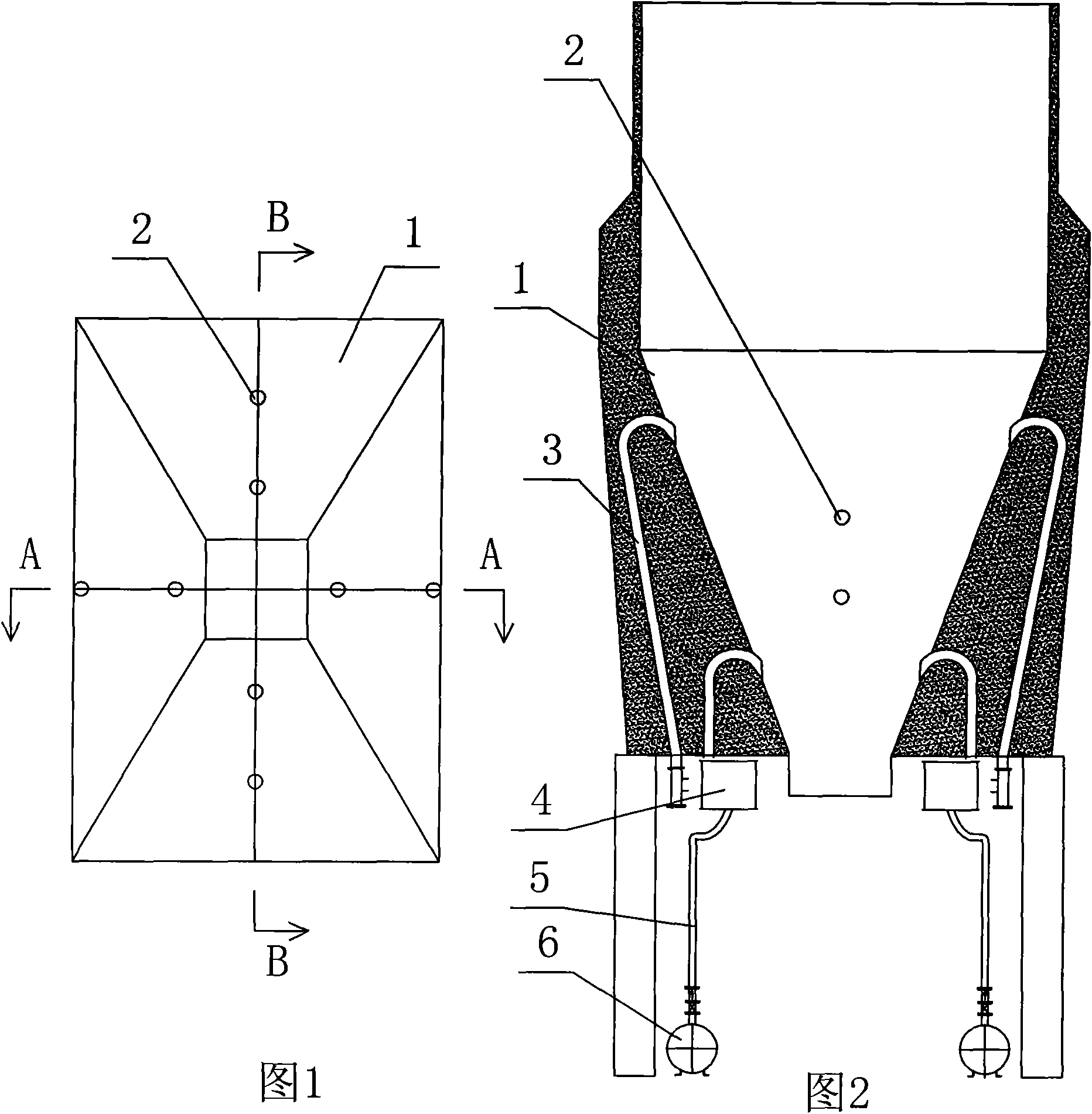

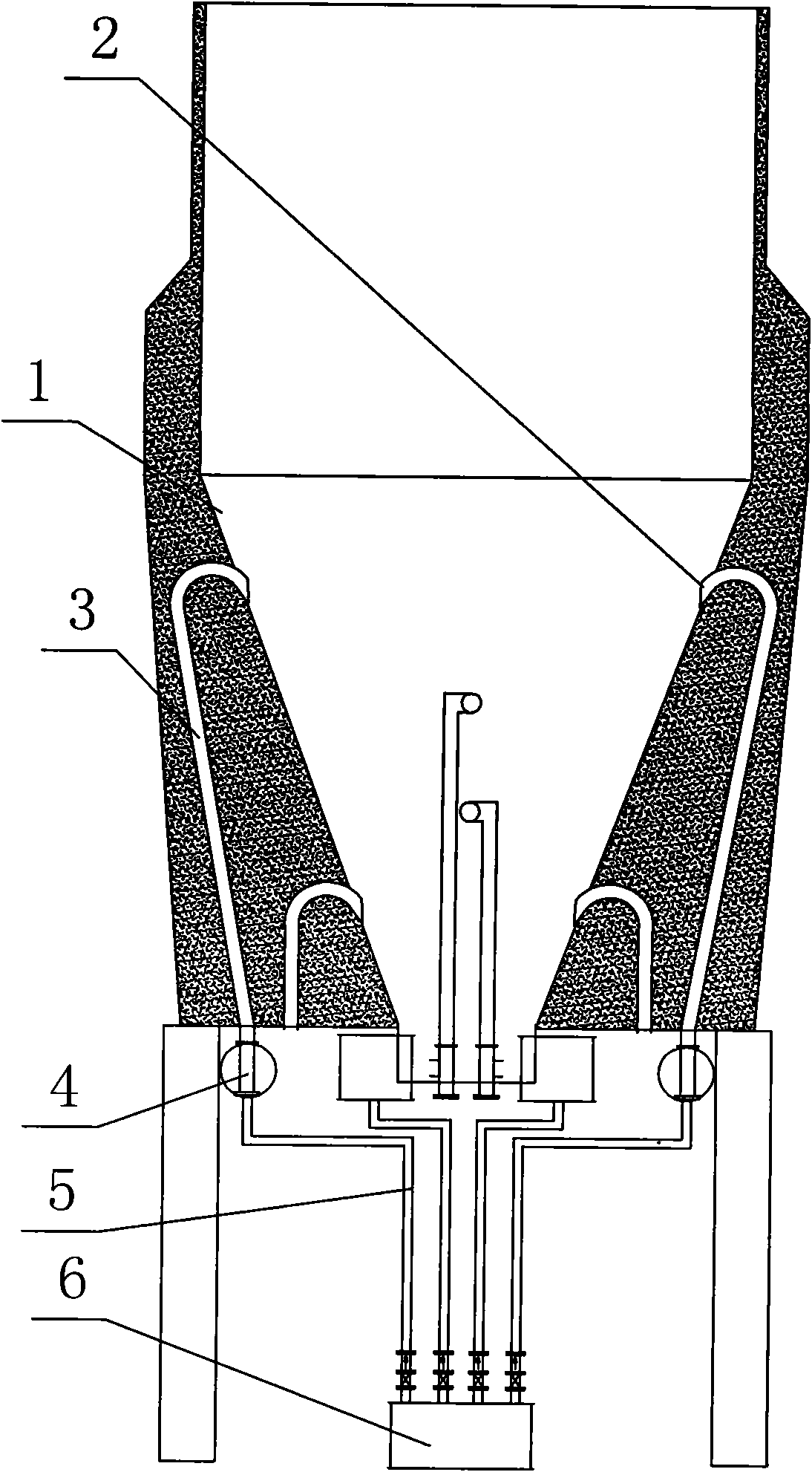

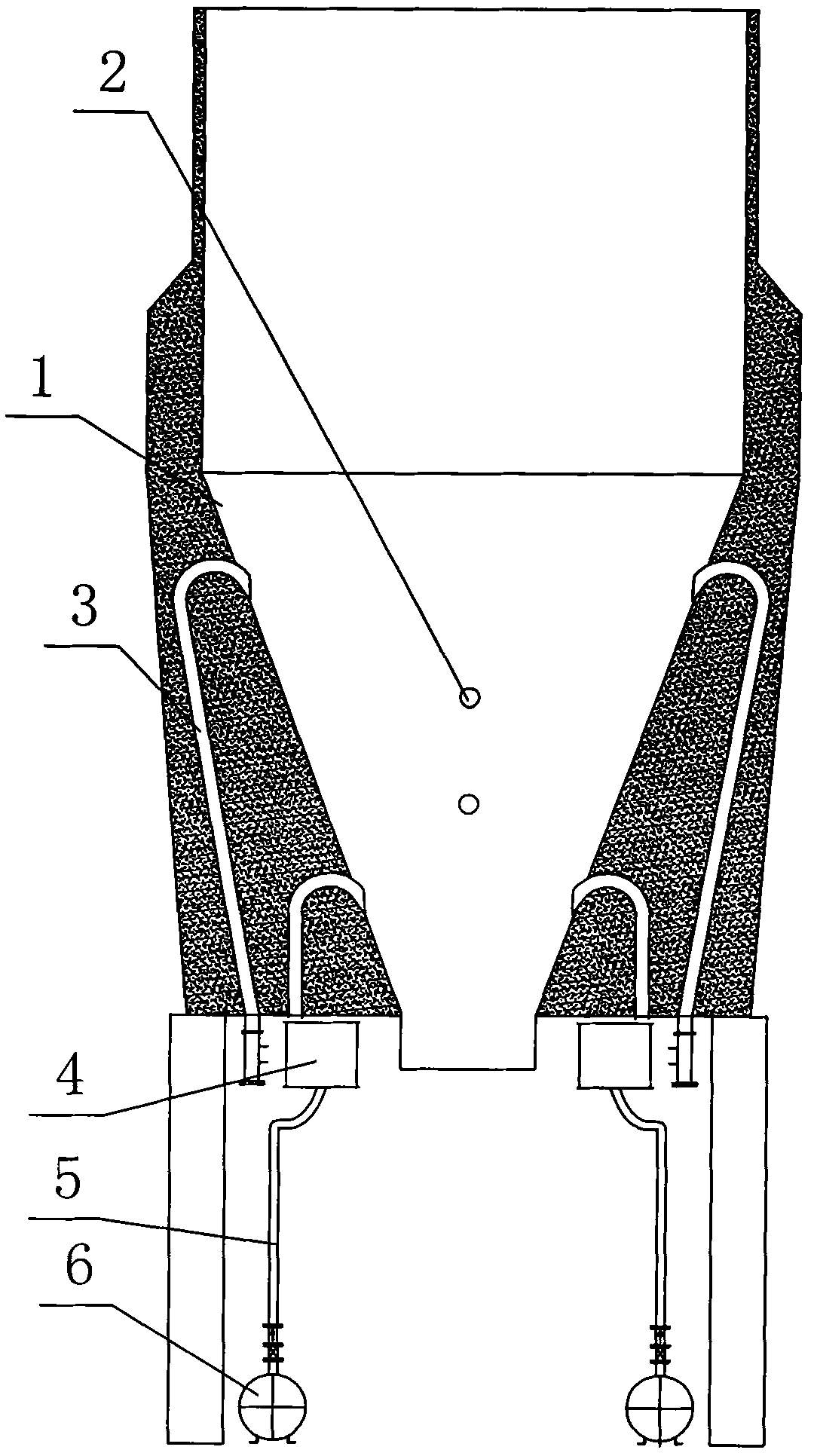

[0012] Example: such as Figure 1-3 The shown installation structure of the downhole air cannon includes a pyramid-shaped funnel 1, and at least two exhaust ports 2 are arranged in the center of each cone surface inside the pyramid-shaped funnel 1, and the exhaust ports 2 face Obliquely downward; in this embodiment, the funnel 1 is a quadrangular pyramid-shaped structure, and two air outlets 2 are respectively arranged on the four surfaces of the inner wall of the funnel 1 according to the vertical arrangement. The facing direction of the exhaust port 2 is located in the angle region between the slope direction of the inner wall of the funnel 1 and the horizontal direction.

[0013] The rear side of the exhaust port 2 communicates with the air cannon 4 through the exhaust pipe 3 , and the air inlet of the air cannon 4 communicates with the air tank 6 through the air intake pipe 5 . If necessary, a pressure regulating valve can be set on the exhaust pipe 5.

[0014] The gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com