Selvedge warp feeding device for planetary edge weaving device of weaving machine

A supply device and side yarn technology, which is applied in looms, textiles, textiles, and papermaking, etc., can solve the problems that the backward displacement cannot be carried out smoothly, and the tension of the side yarn 20 is reduced, so as to achieve long-term and prevent excessive reduction , the effect of mitigating impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

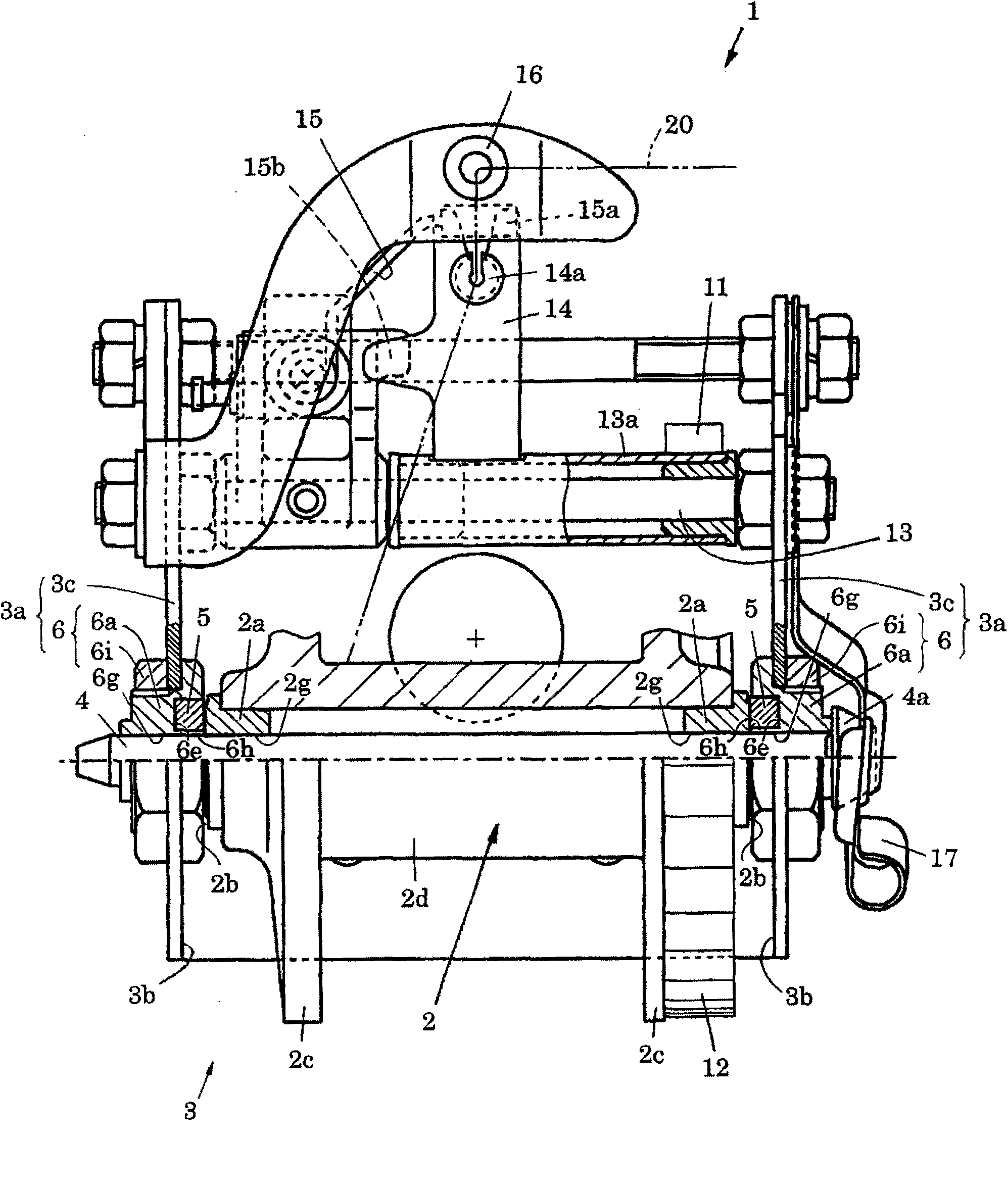

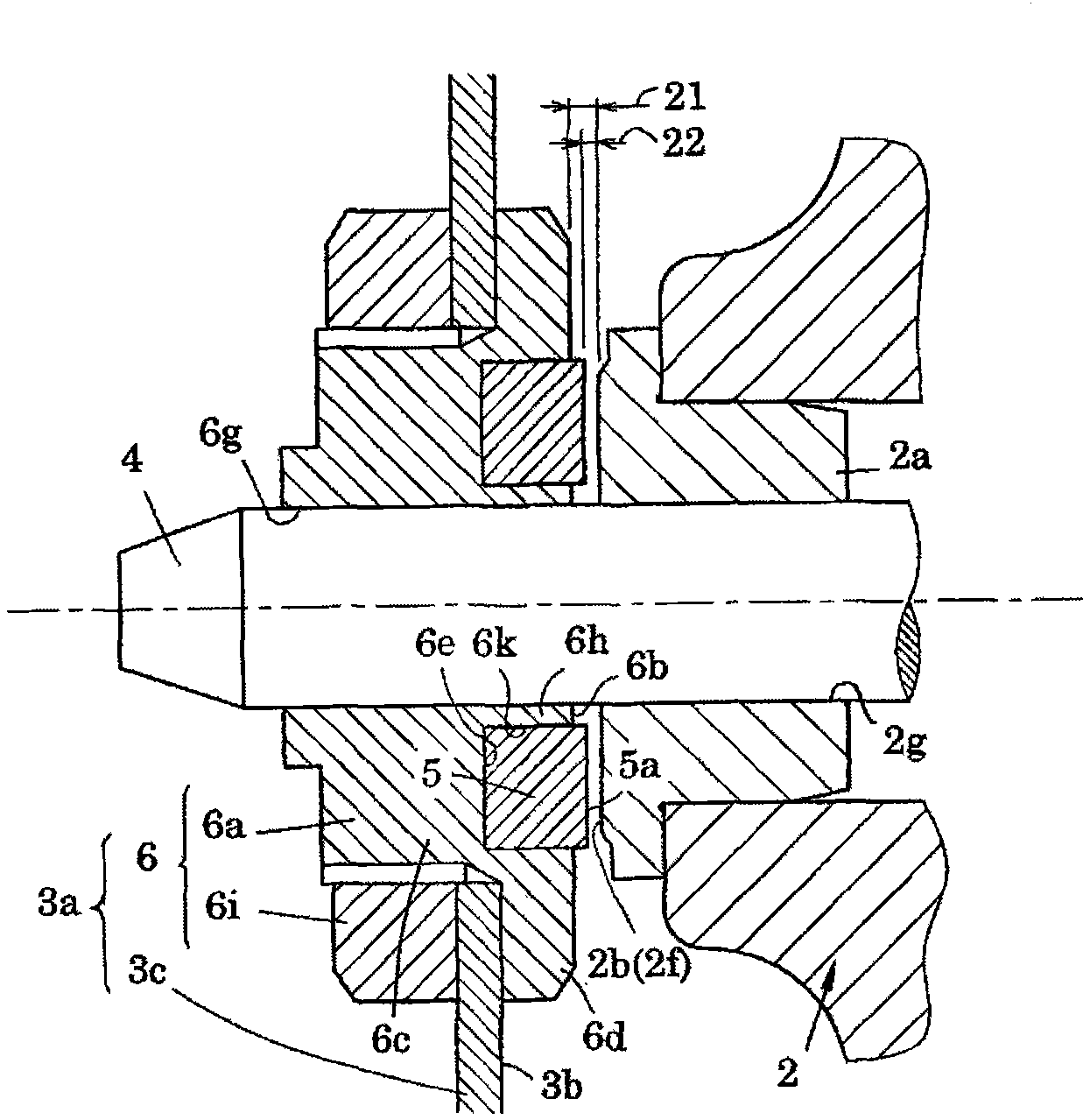

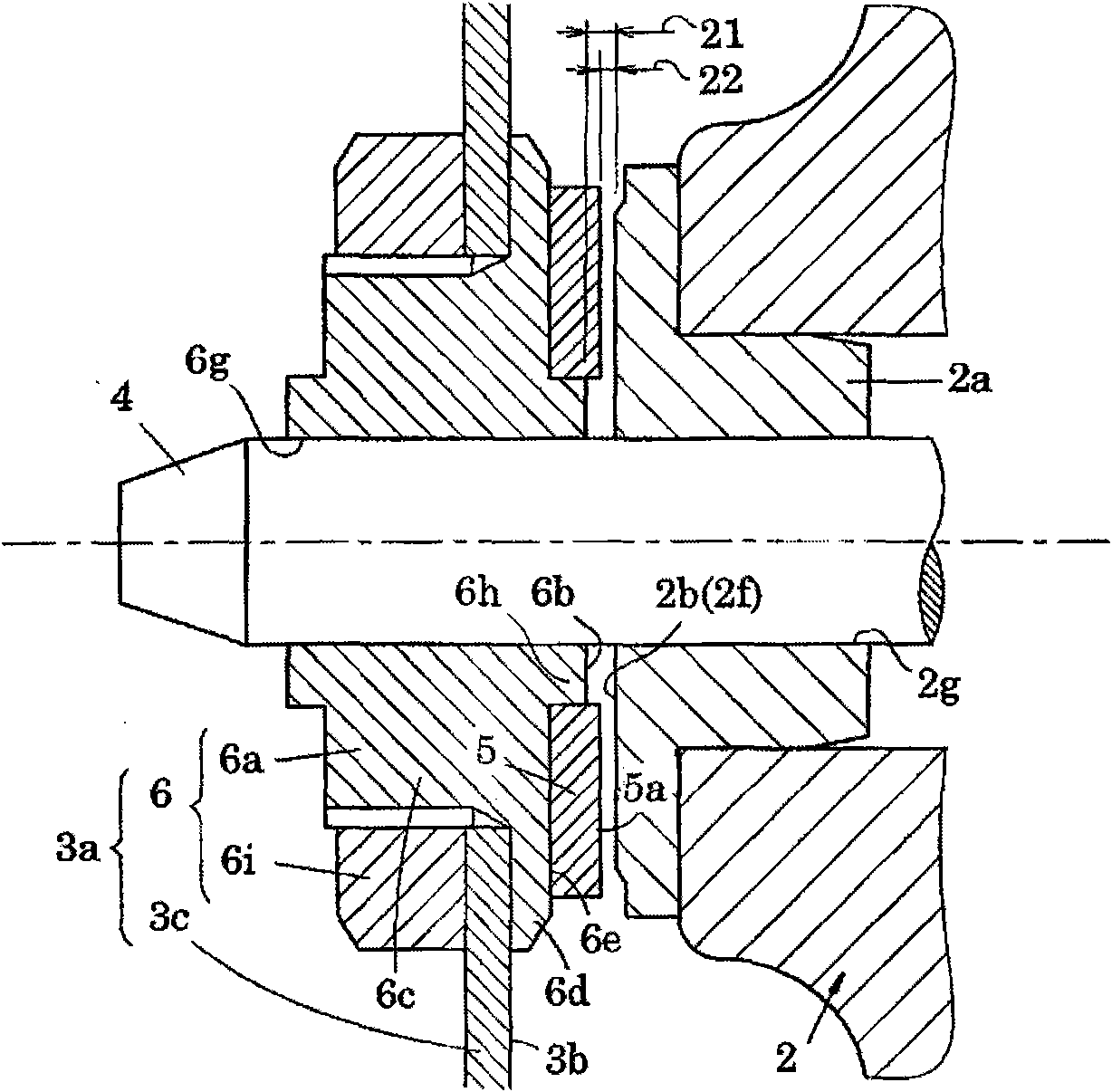

[0055] figure 1Shown is an embodiment of a hemming yarn supply device 1 for a planetary selvedge device on a loom according to the present invention. The side yarn supply device 1, roughly speaking, has: a side yarn bobbin 2 around which a side yarn 20 is wound, a bobbin holder 3 for holding the side yarn bobbin 2 rotatably by a bobbin shaft 4, and a side yarn The tension of 20 is kept within a certain range of tension adjustment mechanism (pawl 11, ratchet 12, driven arm 14, tension arm 15, etc.). In addition, the overall structure of the planetary selvedge device with the side yarn supply device 1 is installed, because it is compatible with Image 6 The conventional planetary selvage device shown is the same, so the explanation is omitted here.

[0056] The edge yarn bobbin 2 has a cylindrical main body portion 2d around which the edge yarn 20 is wound, and a pair of bobbins 2c formed on both ends of the main body portion 2d to guide the edge yarn 20 . In the axial center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com