Screw component

A technology of screw parts and multi-parts, applied to threaded fasteners, screws, nuts, etc., can solve the problem of high cost of special wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0110] In the different figures, parts that are identical or correspond to one another are always provided with the same reference symbols and are therefore generally only described once below.

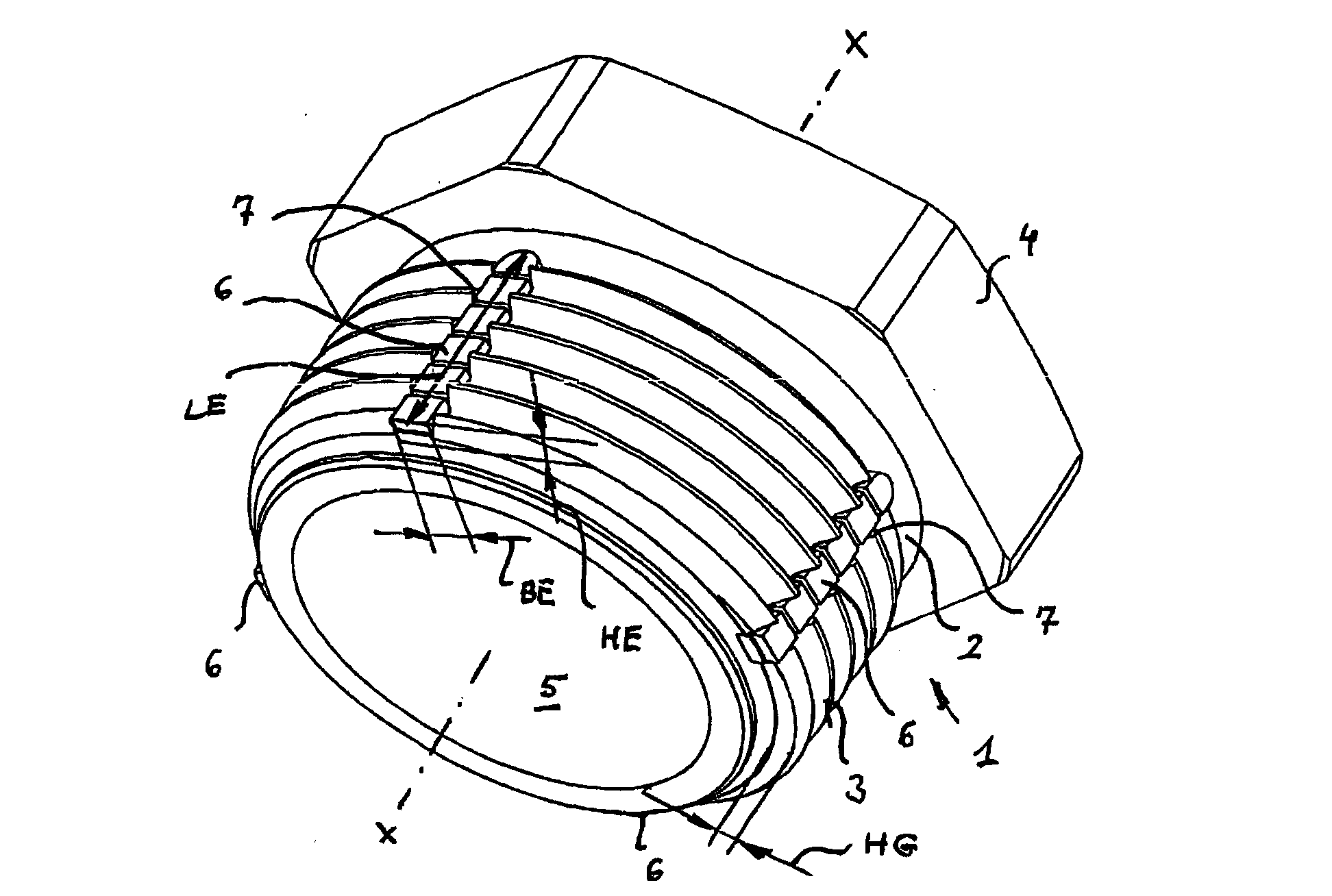

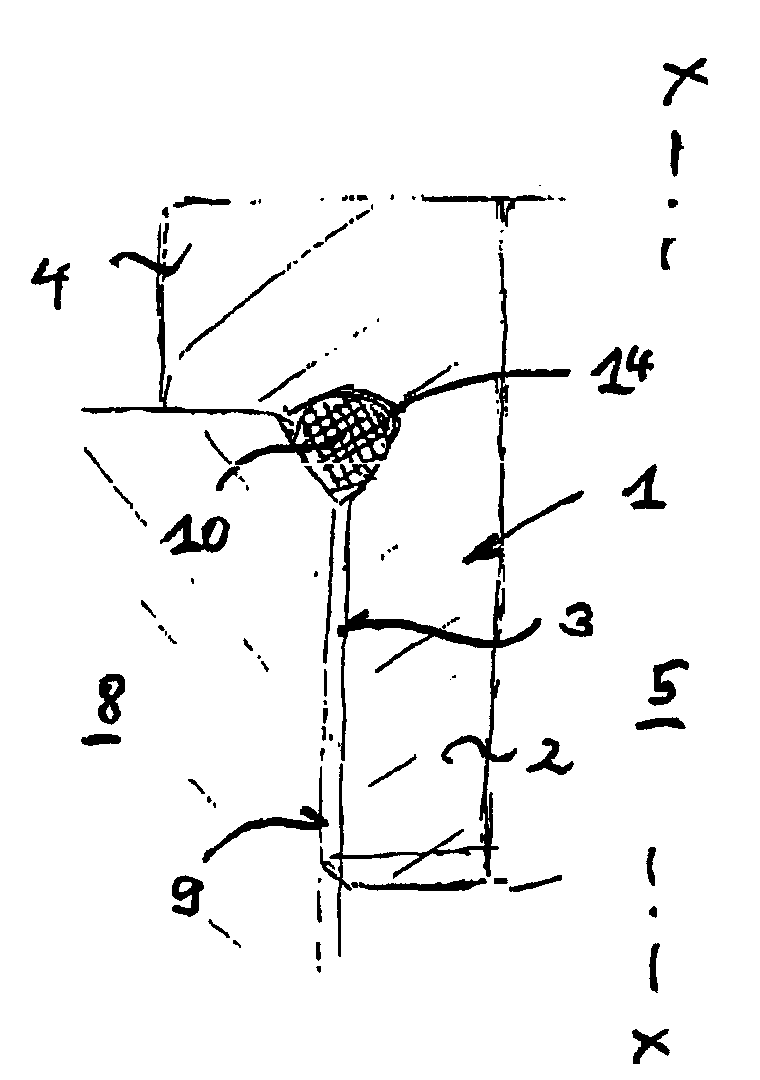

[0111] figure 1 A first embodiment of a helical part 1 according to the invention is shown. Such a screw part has a base body 2 on which a thread 3 is provided. Said base body 2 has the configuration of a hollow cylinder with a longitudinal axis identified with the reference X-X. figure 1The shown screw part 1 is in particular a nut, that is to say a component with a rotationally symmetrical cross section, in particular with a circular or at least partially circular cross section. The base body 2 of the screw part 1 is in particular a molded part which can be produced in an injection molding process, according to the invention, after the injection molding of the base body 2 is completed, at least one second part is subsequently injected. The matrix 2 of the molded part can be produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com