Secondary optical lens of LED street lamp

A technology of secondary optical lens and LED street lamp, which is applied in the direction of light source, point light source, semiconductor device of light-emitting element, etc. The influence of small light efficiency, the effect of LED secondary light distribution is obvious, and the effect of increasing light efficiency utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

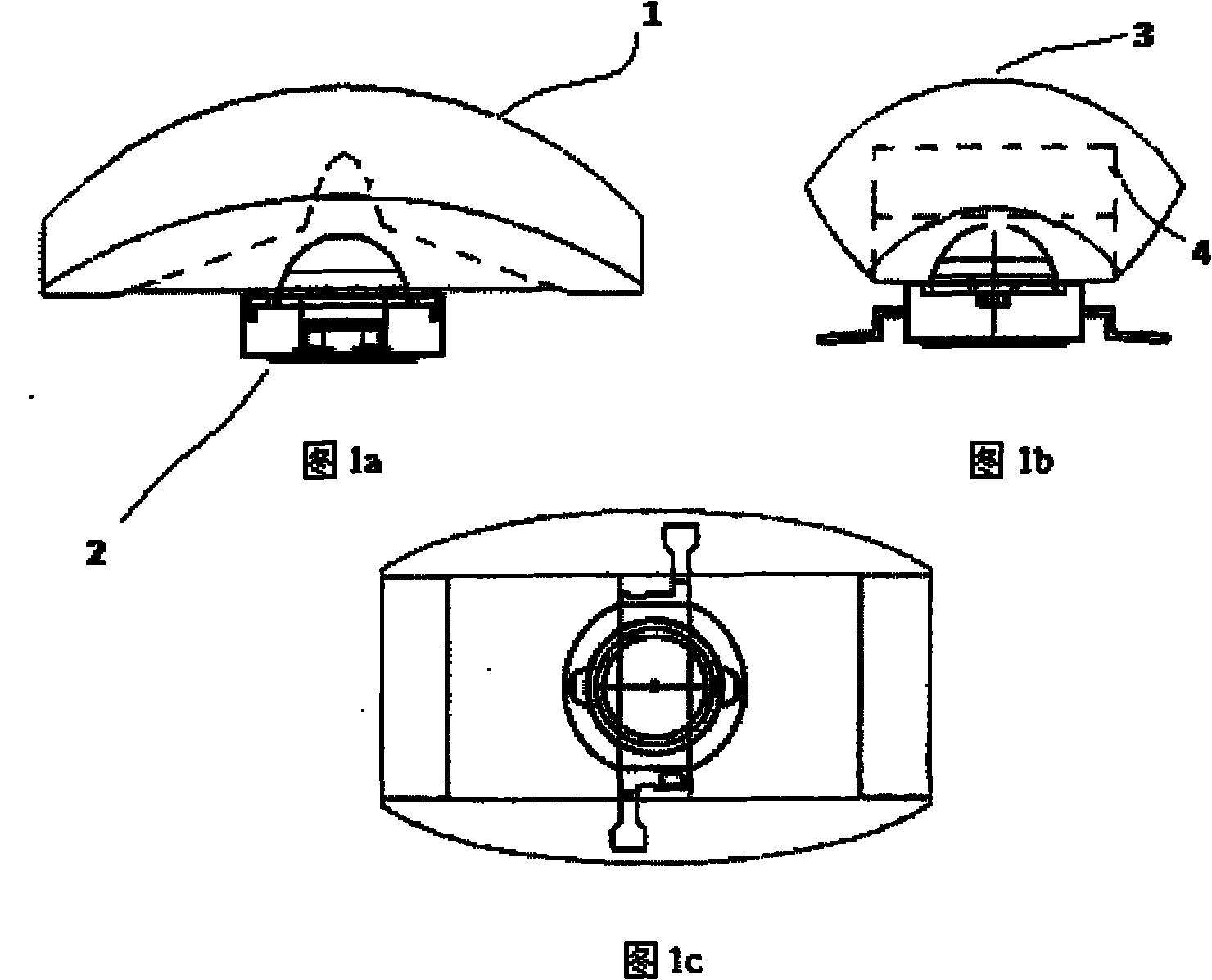

[0025] Referring to Figure 1-3, the combination structure of LED and lens under various viewing angles is given, in which transparent body 1 is the lens part, and 2 is a single LED light source. The lens part consists of an outer curved surface 3 and an inner curved surface 4 .

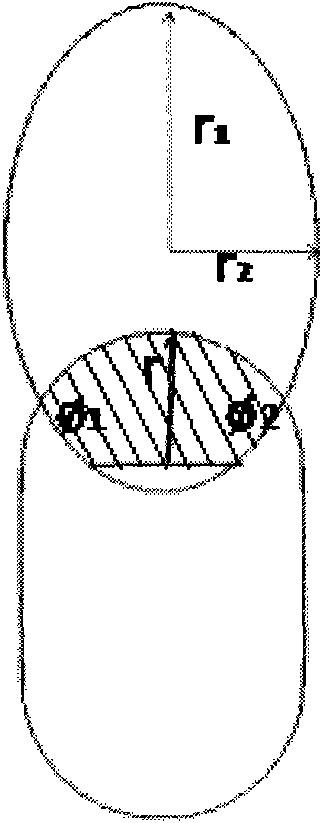

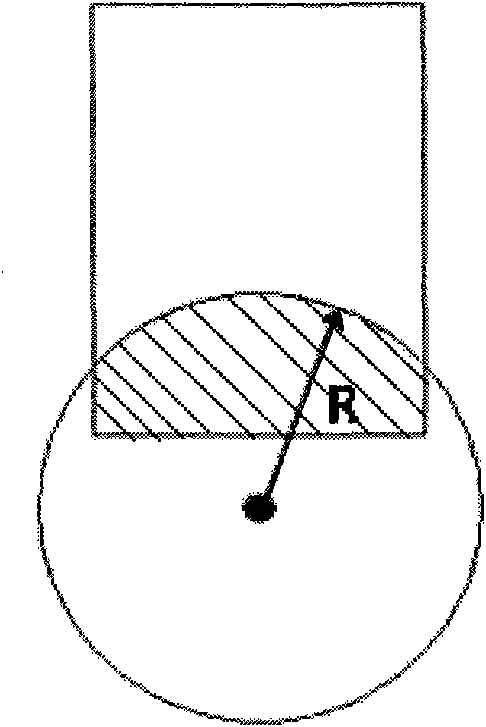

[0026] As shown in Figures 2 and 3, the outer curved surface 3 of the lens is a curved surface body formed by cutting a torus through an elliptical cylinder (Fig. 2) with a certain length and radius. In Fig. 3, surface 5 is the upper surface of the outer curved surface. It is in the shape of an ellipsoid, and the radian of the surface is determined by the radius R of the outer circle of the ring and the radius r of the inner circle. The arc surface generated by cutting the ring body, radian (φ 1 and φ 2 ) and the sides of the elliptical cylinder are equal, mainly determined by the long and short radii (r1 and r2) of the elliptical cylinder.

[0027] The inner curved surface 4 of the lens is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com