Pressed punching production stoppage-free temperature measuring method for pipeline

A technology for pipes and temperature measuring holes, which is applied in the field of pipe pressure drilling and temperature measurement without production shutdown, can solve problems such as interruption of transportation production, hidden dangers of safety, and low construction efficiency, and achieve the effect of reducing production costs, convenient use, and reducing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0021] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

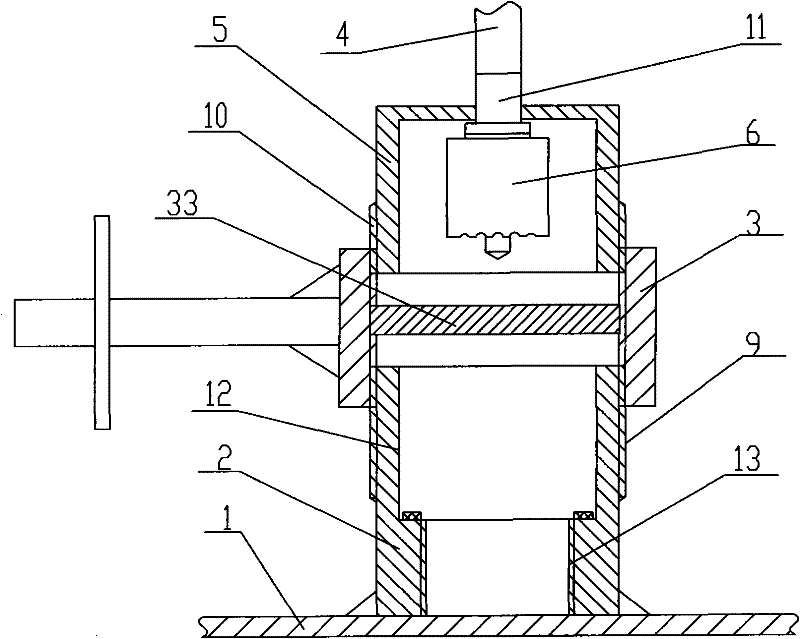

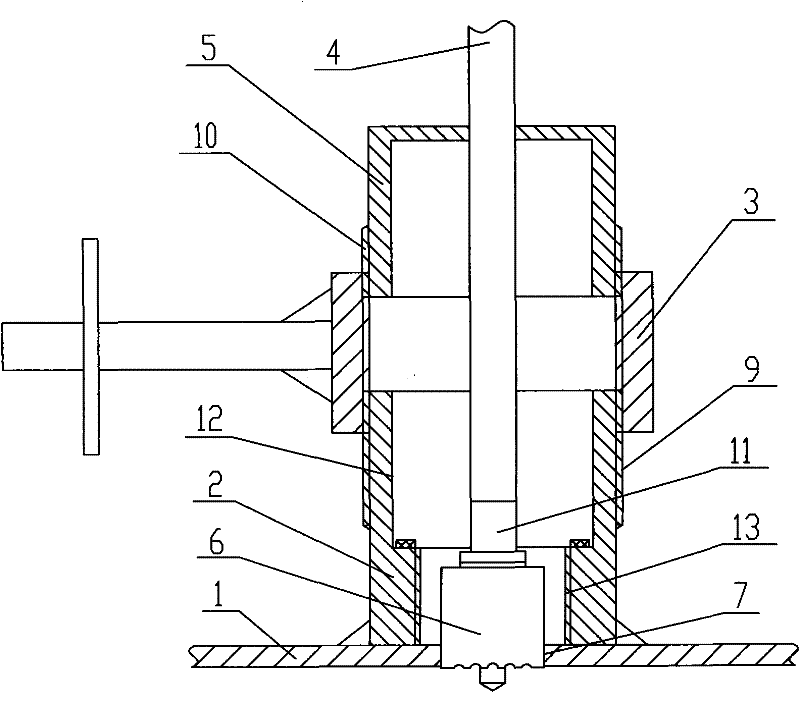

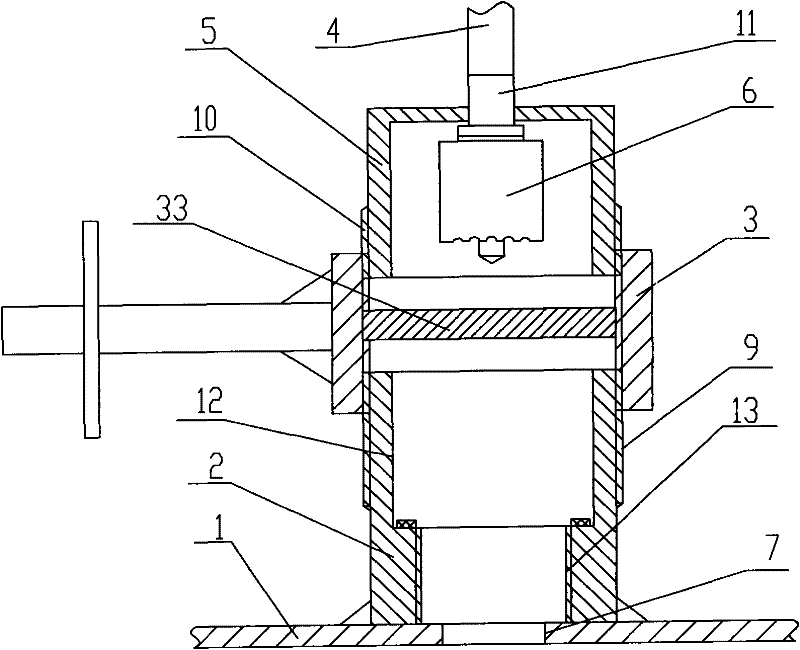

[0022] The temperature measurement method of the pipe under pressure without stopping production is carried out according to the following steps: first weld the casing mounting seat 2 on the pipe 1, and install the valve 3 on the upper part of the casing mounting seat 2; figure 1 As shown, a hole tapping machine connection housing 5 with a hole hole shaft 4 is installed on the valve 3, and a hole hole knife 6 is installed at the lower end of the hole hole shaft 4, as shown in the attached figure 2 As shown, open the valve 3 and punch the temperature measurement hole 7 on the pipeline 1 with the hole knife 6; image 3 As shown, after the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com