Method for detecting air tightness of 12 stations of automotive water seal

A technology of air tightness detection and air tightness detection, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the problems of manual observation, non-quantitative, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

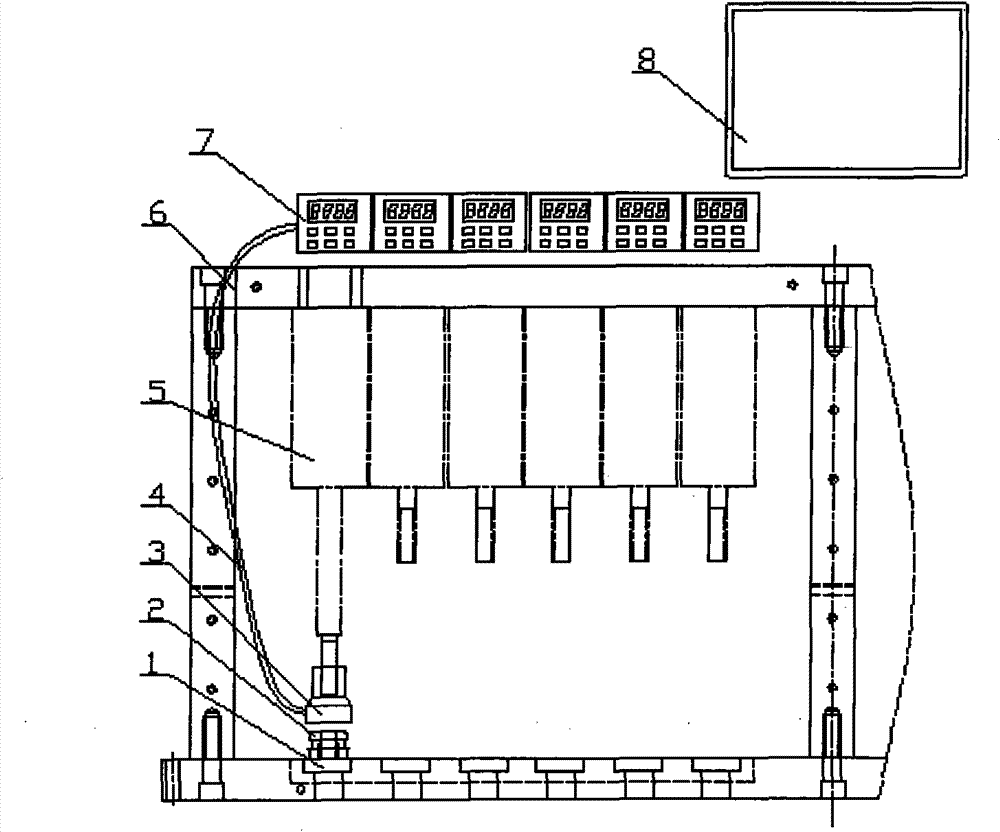

[0010] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] The present invention realizes that the leakage air bubbles are collected and converted into a pressure difference signal to enter into a pressure difference sensor, and then converted into an electric signal for detection, judgment and sorting.

[0012] As shown in the drawings, the present invention includes an airtight detection lower mold 1, an airtight detection upper mold 3, a leakage gas collection pipe 4, a mold pressing cylinder 5, a frame 6, a micro pressure difference sensor 7, and a touch control panel 8, Wherein, the bottom of frame 6 is provided with a plurality of evenly arranged airtight detection lower dies 1, and directly above the airtight detection lower die 1 is provided with a mold pressing cylinder 5 corresponding to one of them, and the lower part of the mold pressing cylinder 5 is provided with There is an airti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com