Solar gravity heat pipe vacuum liquid-filling device

A technology of gravity heat pipe and solar energy, applied in indirect heat exchangers, lighting and heating equipment, etc., to achieve high efficiency, avoid low precision, and effective and reliable vacuuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

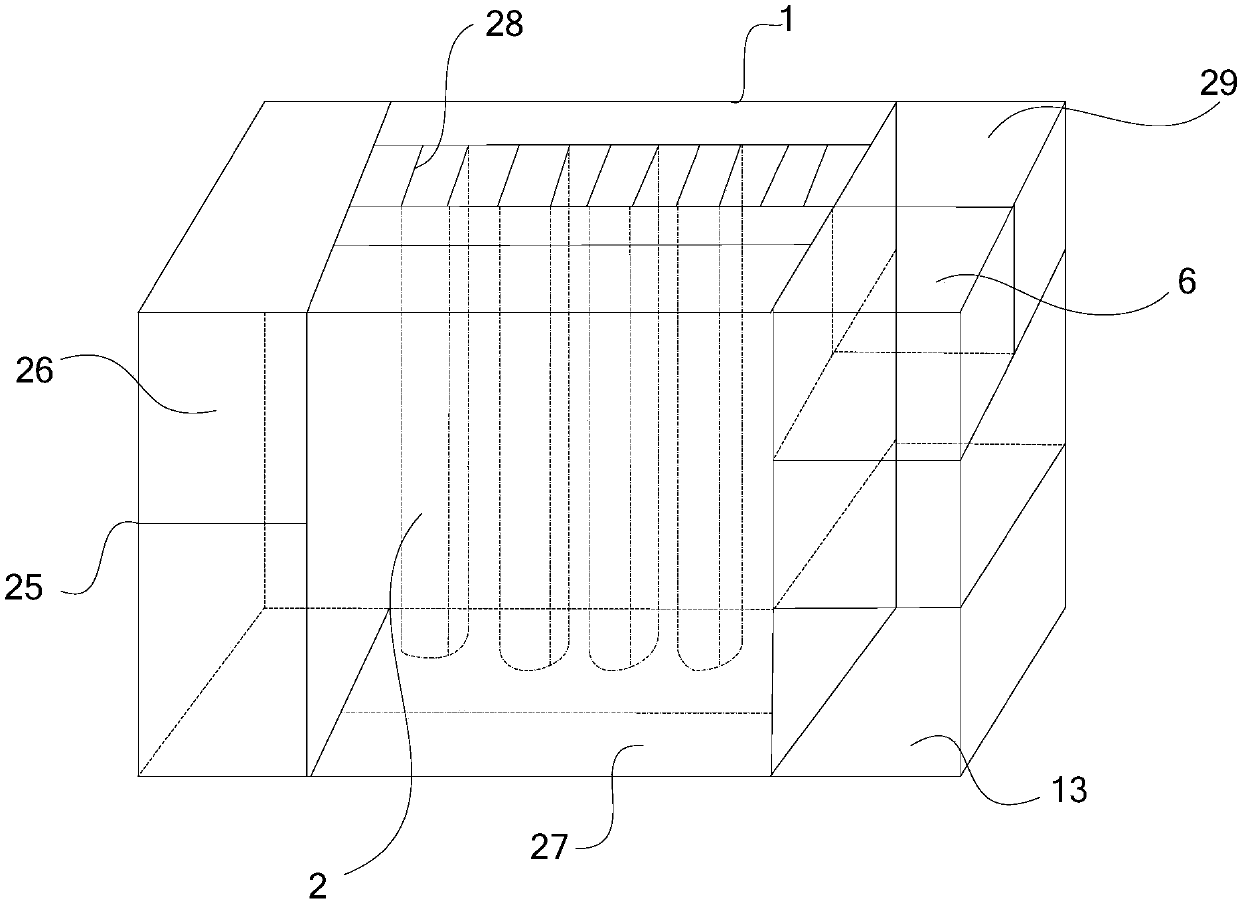

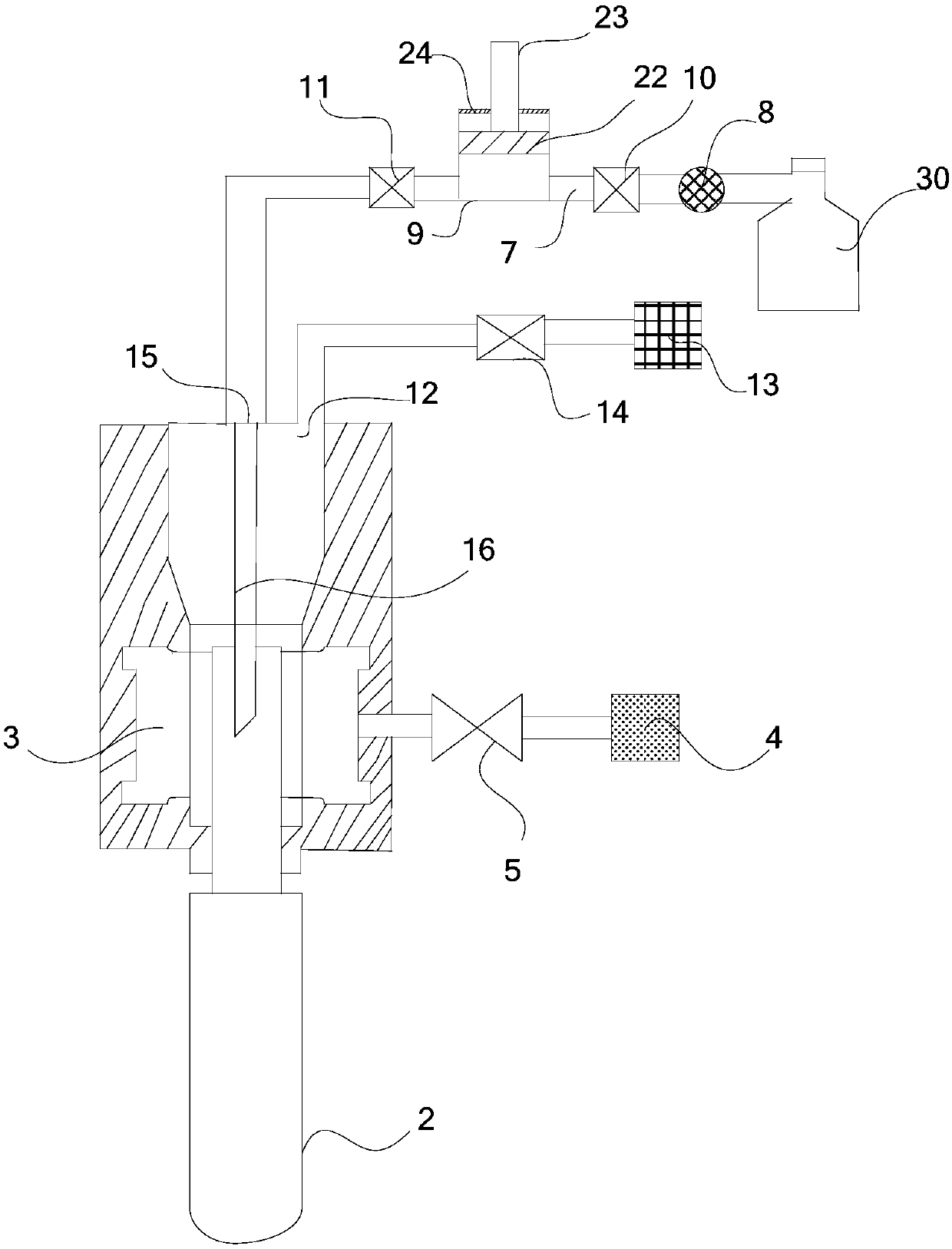

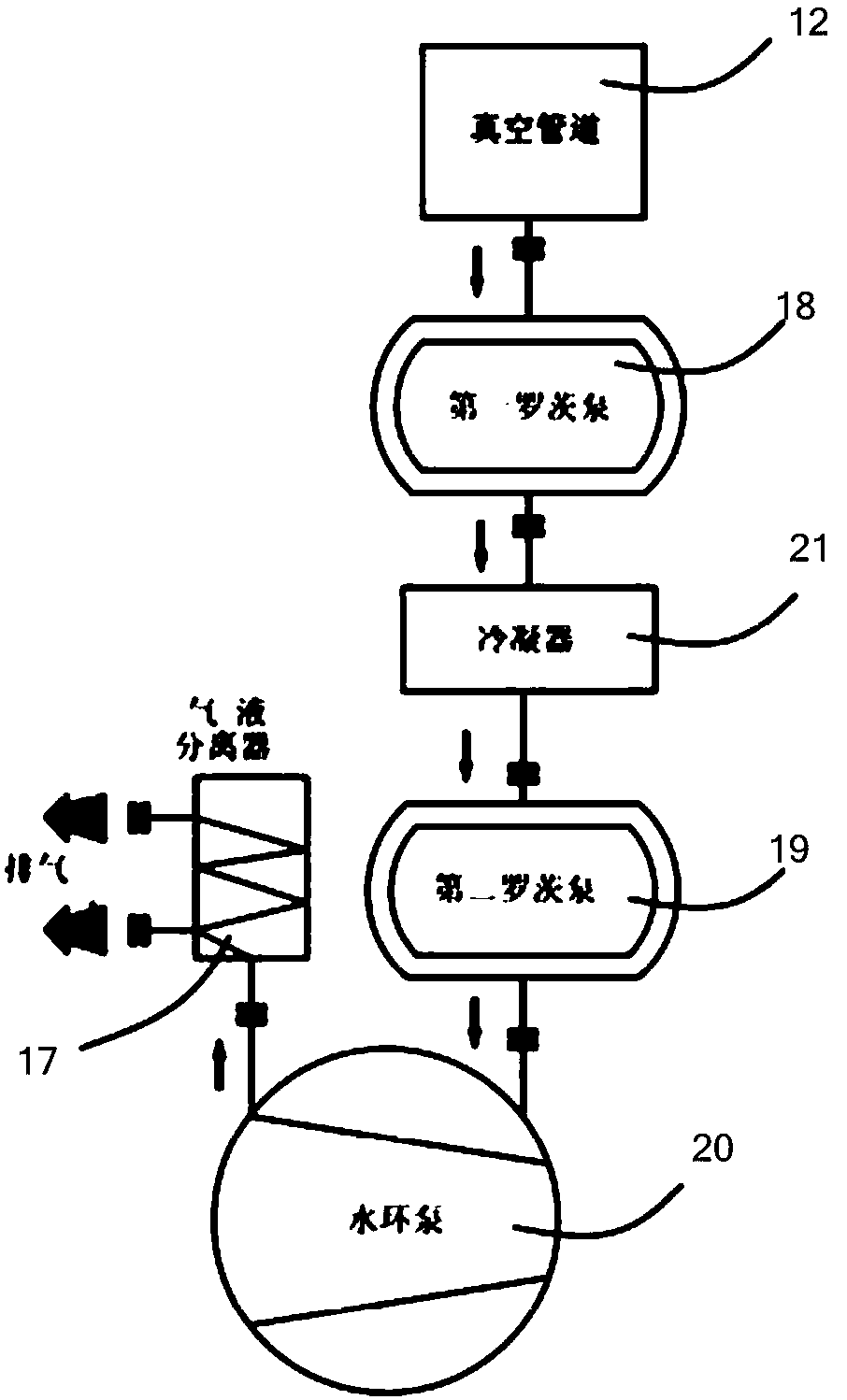

[0029] Such as figure 1 and figure 2 As shown, the present invention provides a solar gravity heat pipe vacuum liquid filling device, including: a frame 1, a heat pipe positioning mechanism, a liquid filling mechanism and a vacuum mechanism. The heat pipe positioning mechanism is used for positioning the heat pipe 2 to be filled with liquid, the liquid filling mechanism is used for filling the heat pipe 2 with working fluid, and the vacuum mechanism is used for evacuating the heat pipe 2 to a set vacuum degree.

[0030] The heat pipe positioning mechanism includes a heat pipe 2 fixing assembly arranged on the bottom plate of the frame 1; the heat pipe fixing assembly includes a quick-sealing air bag 3, a gas compressor 4 suitable for pressurizing the air bag 3, and a gas compressor 4 and an air bag. The air bag solenoid valve 5 between 3, the air bag 3 is provided with an inflation port. The gas used for sealing the air bag 3 designed in this embodiment is nitrogen, that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com