A method of using metal powder powder column coupling

A technology of metal powder and grain, which is applied in the field of metal powder grain coupling, and can solve problems such as poor storage performance, difficulty in ignition, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further explanation below in conjunction with accompanying drawing

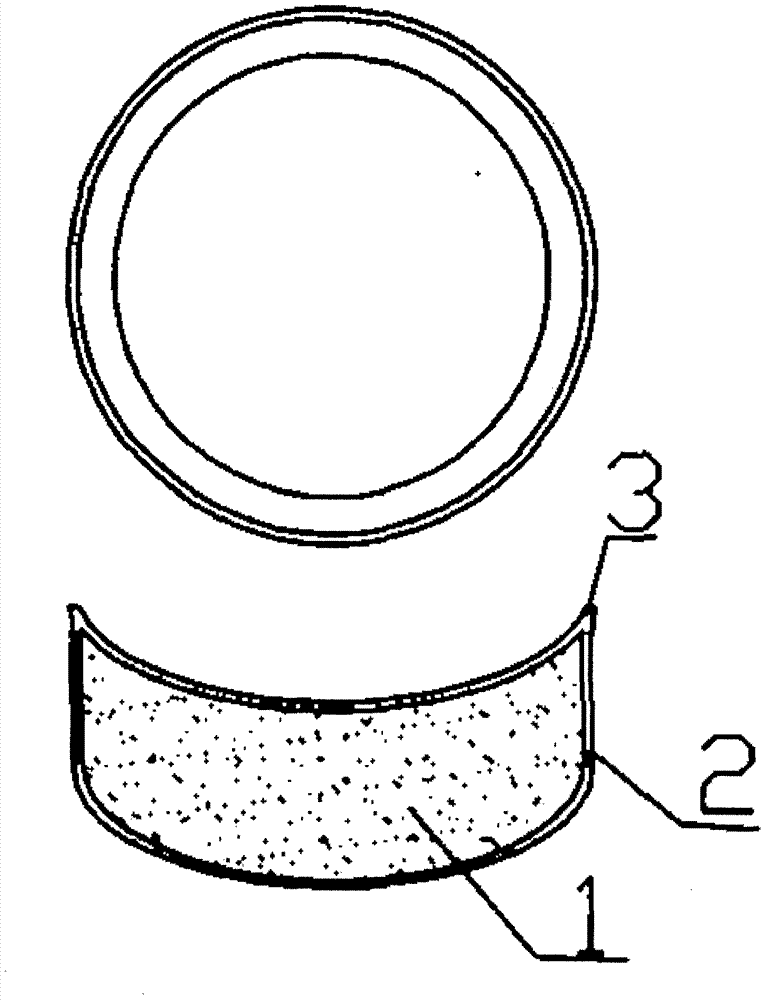

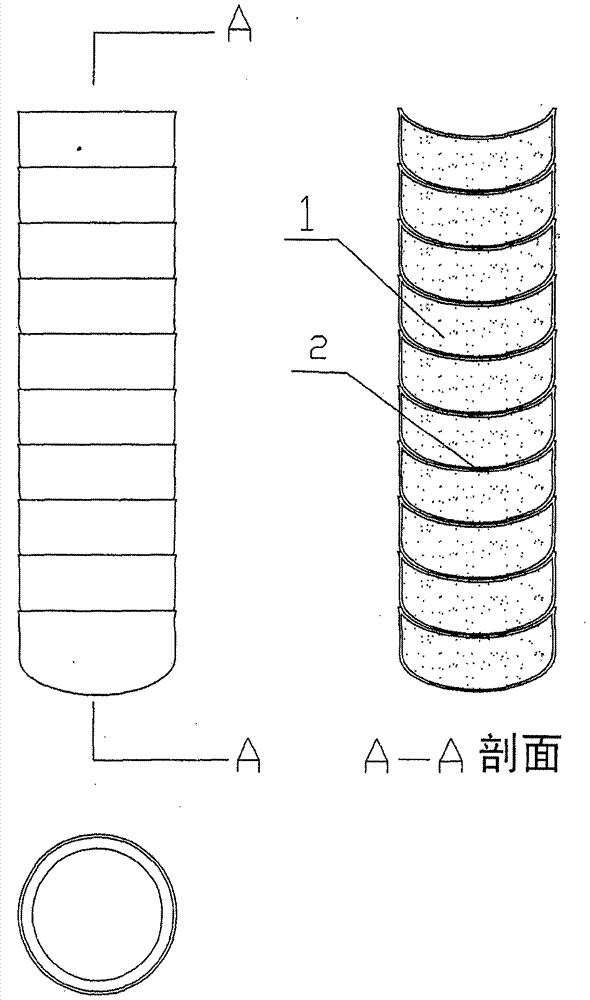

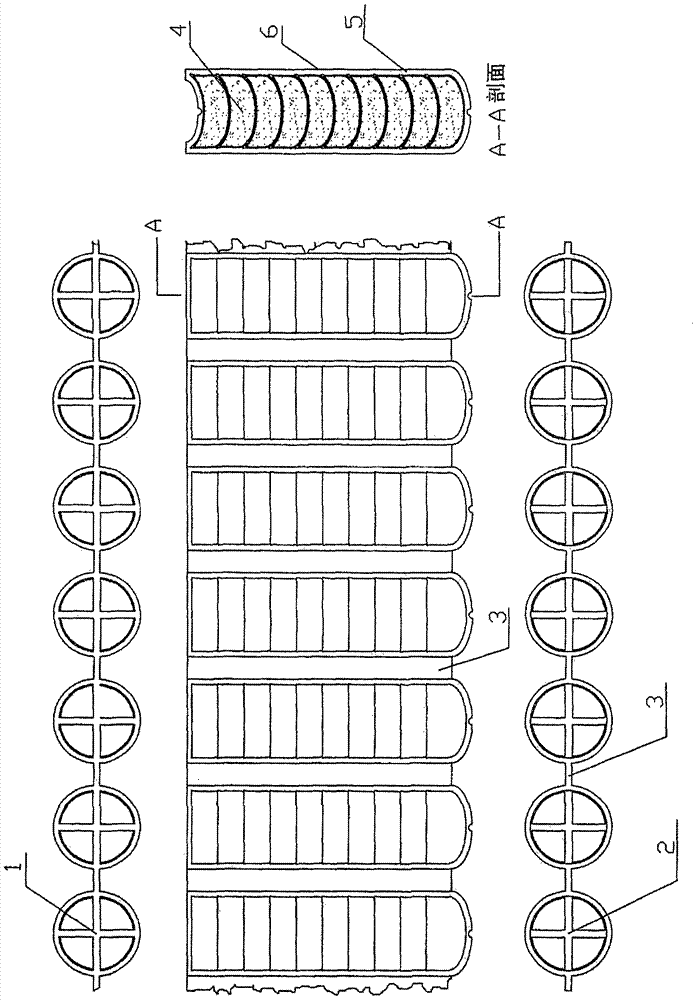

[0021] A metal powder grain coupler according to the present invention includes several metal powder grains, and the metal powder grains and the metal powder grains are encapsulated by an organic polymer mold to assemble into a joint structure. The specific implementation when image 3 It is a schematic diagram of a standard powder column packaged by a metal powder column through an organic polymer film, in which 1- is the dent on the top of the package of the column, 2- is the dent on the bottom of the package of the column, and 3- is the gap between the columns 4-the grain column, 5-is the gas or liquid filler between the grain column and the outer packaging, 6-is the organic polymer film that is resistant to salt spray and seawater erosion; The trace is the weak link in the strength of the cartridge package. The purpose of setting this link is to facilitate the smooth insertion of the filler ejecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com