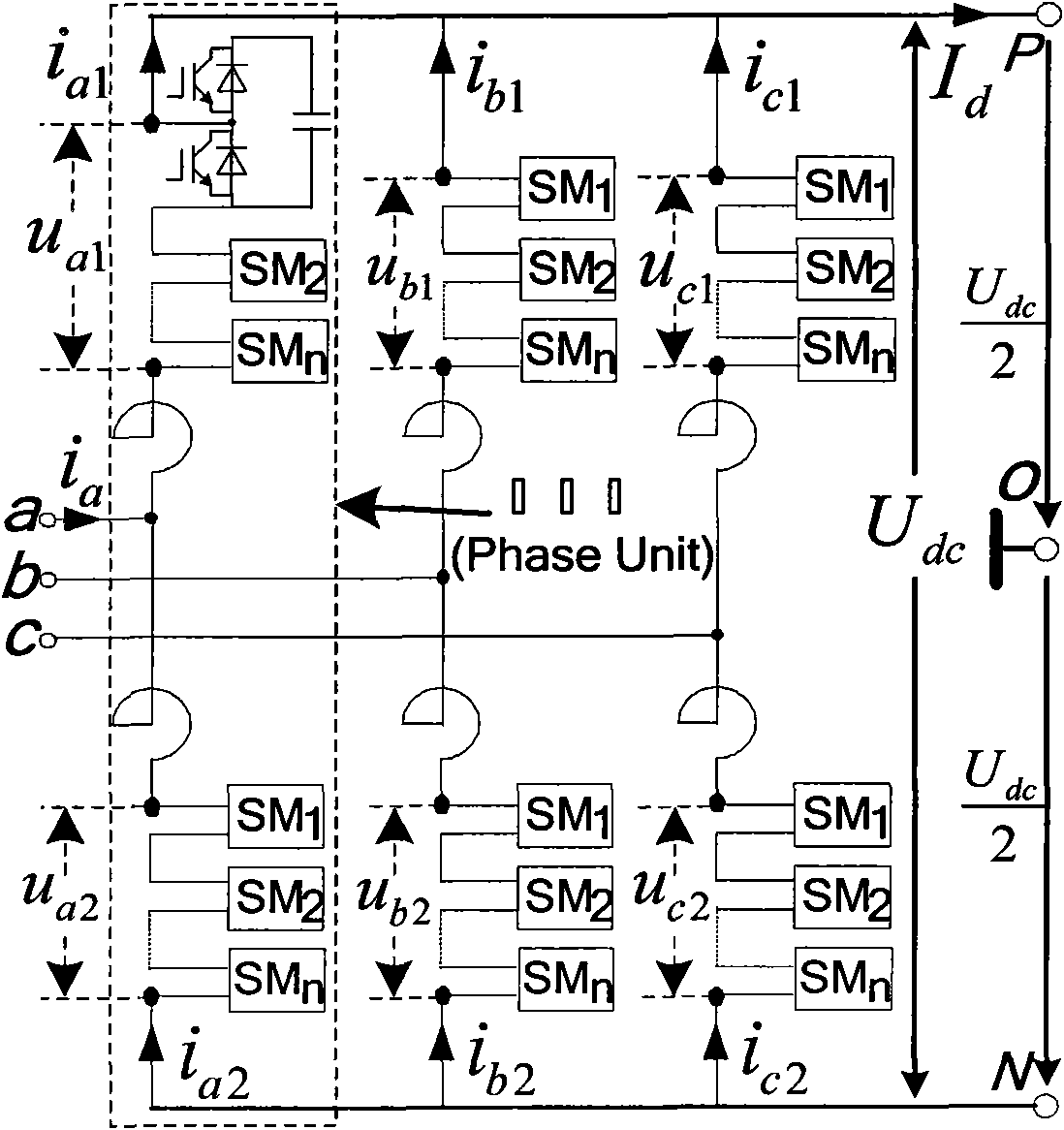

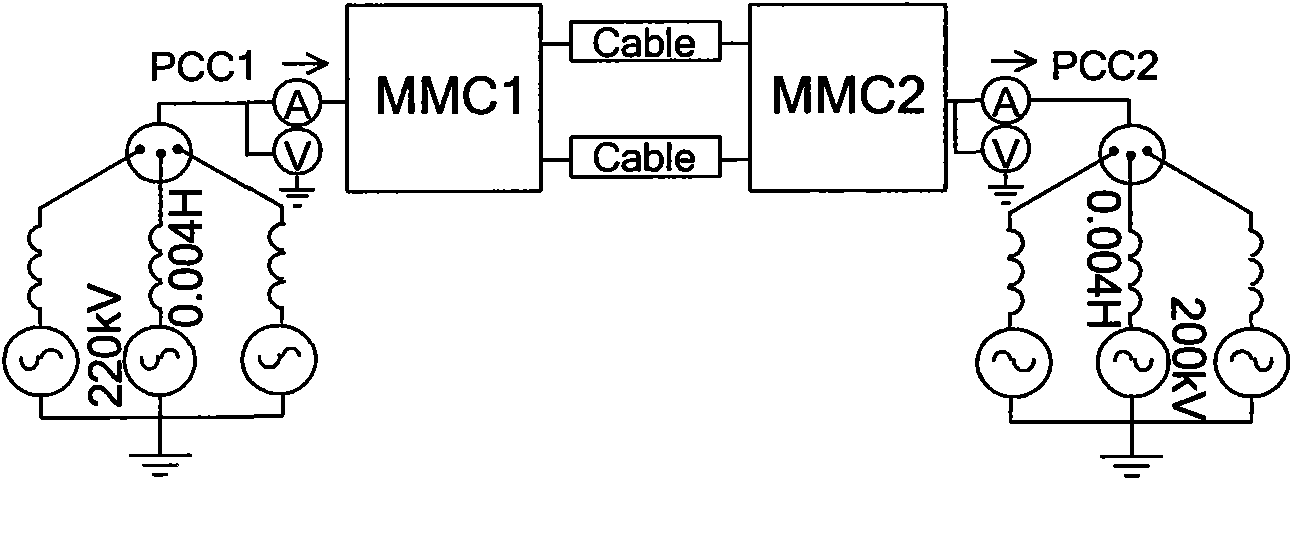

Optimal pressure equalizing control method of modular multilevel converter type direct current transmission system

A DC power transmission system, modularized multi-level technology, applied in the direction of converting AC power input to DC power output without intermediate conversion to AC conversion equipment, electrical components, etc. The efficiency of the level converter type DC transmission system, reducing the speed of the converter to track the modulating wave, etc., to achieve the effect of reducing the switching frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

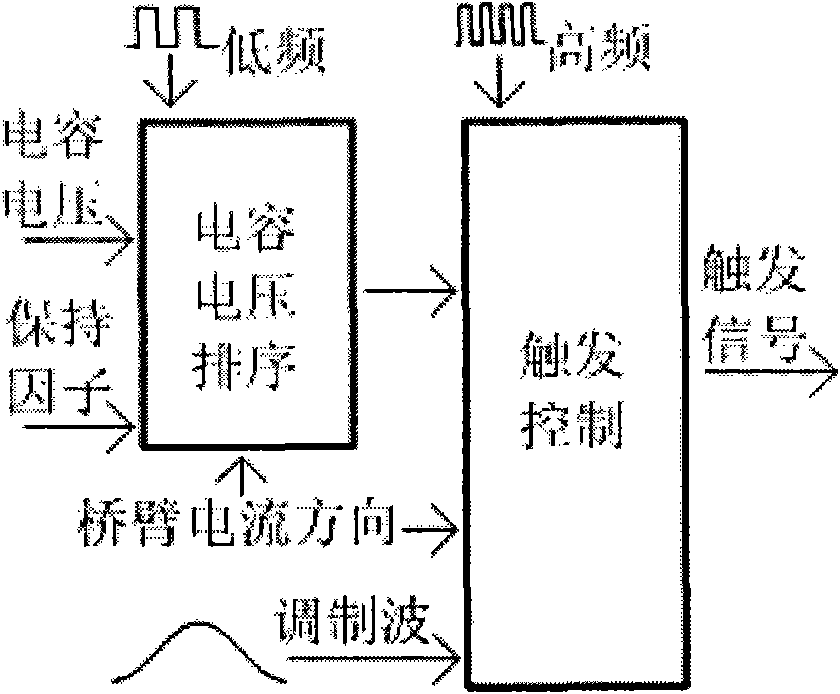

[0022] The optimal voltage equalization control method for the modular multilevel converter type DC transmission system is: set the upper and lower limits of two sets of voltages, the upper and lower limits of the capacitor voltage in mode 1 are 21V and 19V respectively, and the capacitor voltage in mode 2 , The lower limit is 22V and 18V respectively. Combined with the charge and discharge of the bridge arm current, the capacitor voltage sorting of the sub-modules whose capacitor voltage does not exceed the limit is processed to increase the probability that the sub-modules whose capacitor voltage does not exceed the limit will maintain the original switching state when triggering the next action of the control, and reduce the device The switching frequency, the specific processing is as follows:

[0023] If the bridge arm current charges the sub-module, when the trigger control next action tends to input the sub-module with low capacitor voltage, the capacitor voltage of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com