Guide bar shogging device

A bar traversing and bar technology is applied in the fields of warp knitting machines and bar traversing devices, which can solve the problems of inability to change the arrangement of yarn guide needles, which is not conducive to pattern design and daily production management, and achieves convenient and rapid replacement. , compact structure, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

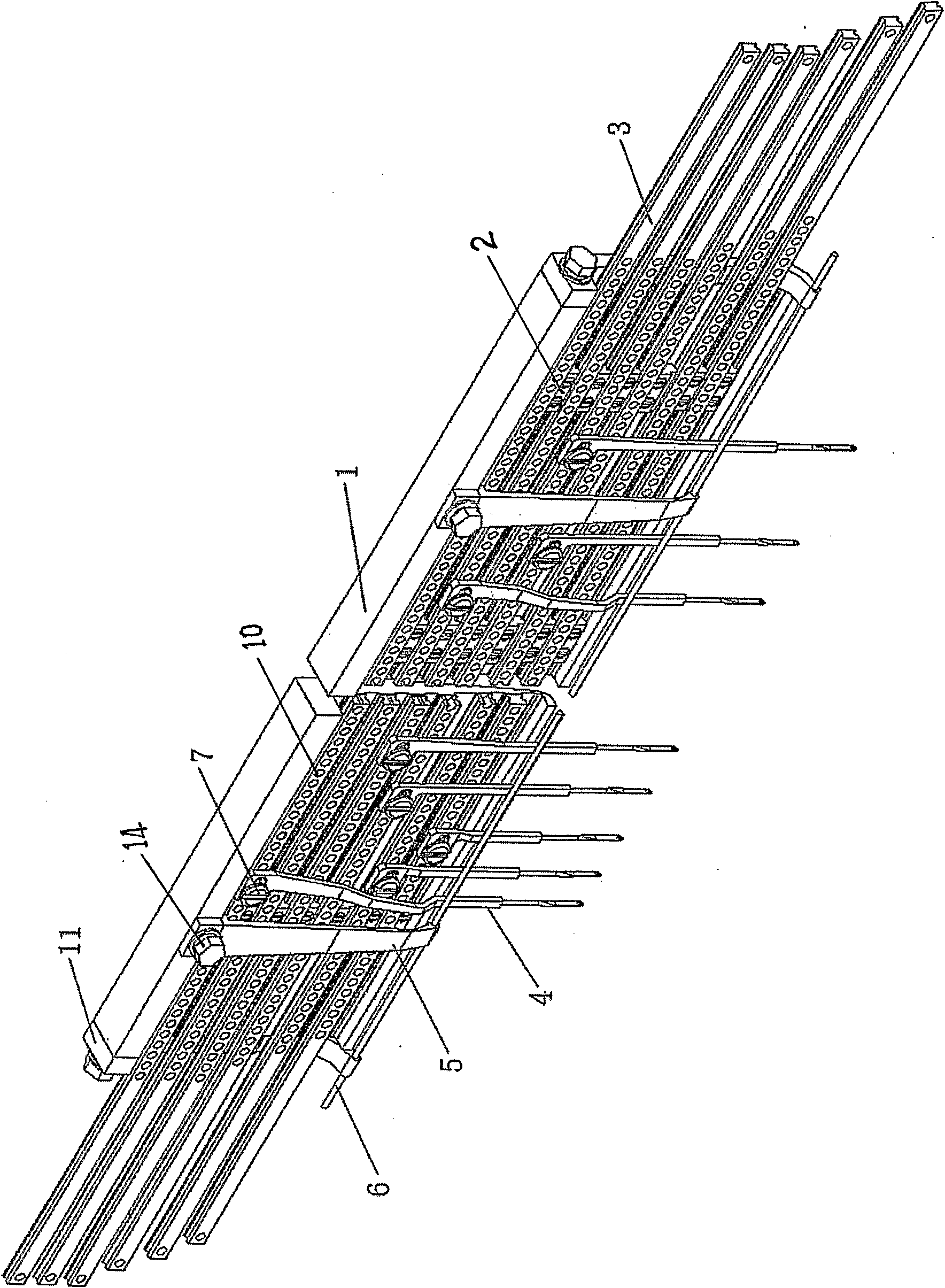

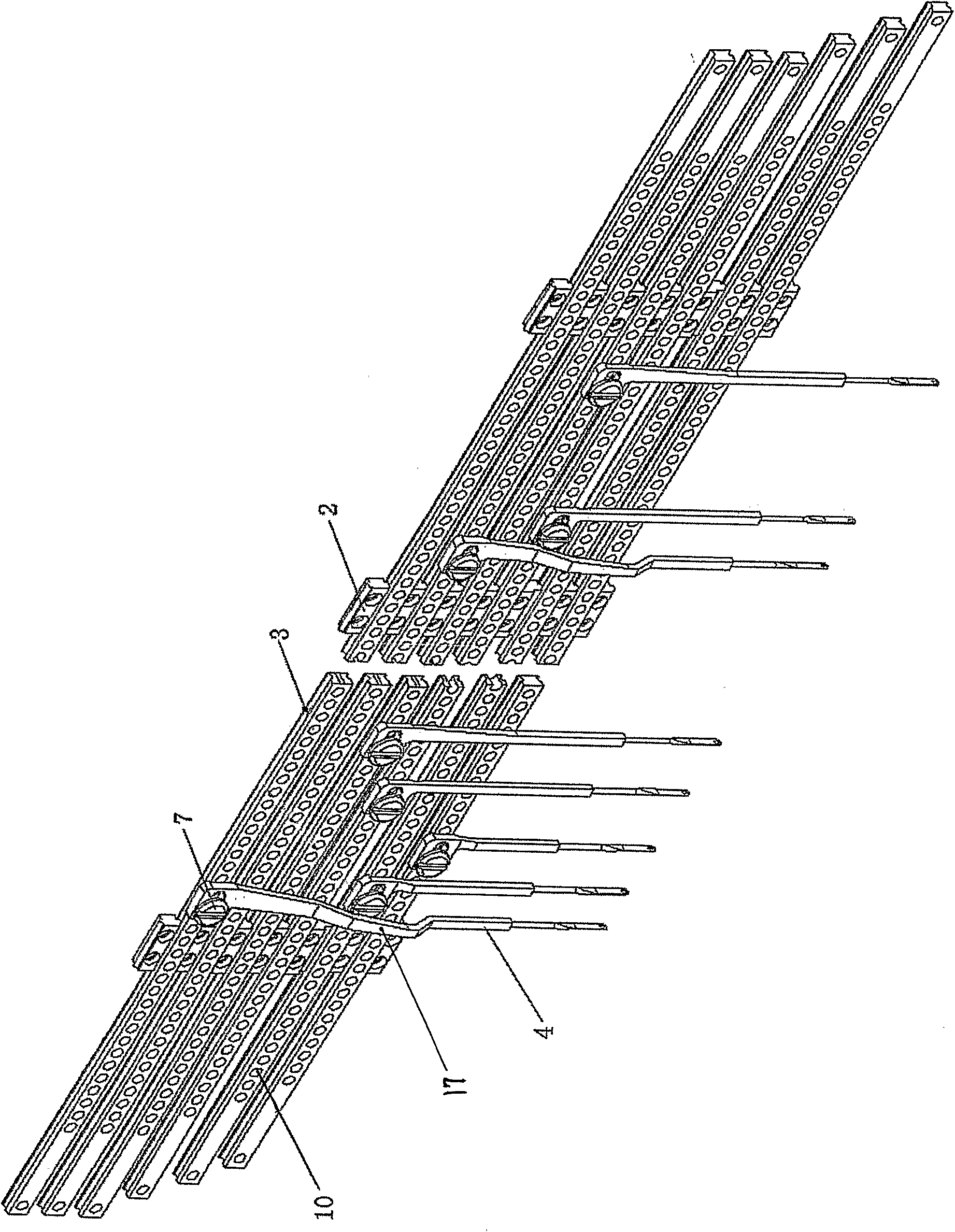

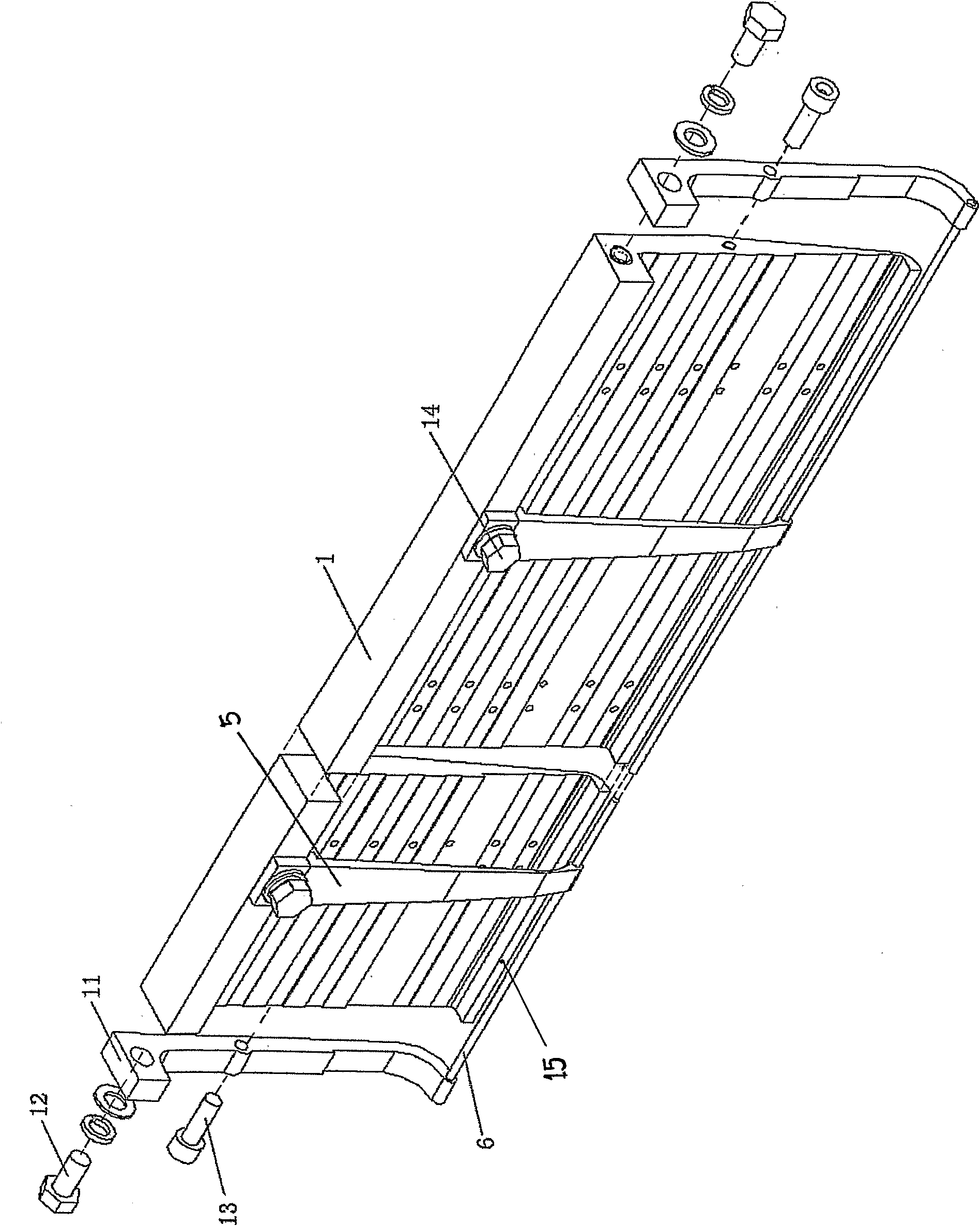

[0015] Referring to the accompanying drawings, 1 in the figure is the bar seat, 2 is the guide rail, 3 is the bar, 4 is the guide needle, 5 is the cover plate, 6 is the needle retaining wire, 7 is the bolt for fixing the guide needle, and 8 is the guide rail 9 is the chute on the bar, 10 is the screw hole on the bar, 11 is the baffle, 12 and 13 are the bolts for fixing the baffle, 14 is the bolt for fixing the cover plate, 15 is the bar The boss on the lower edge of the seat, 16 is the counterbore on the guide rail, and 17 is the bow on the guide needle.

[0016] In the present invention, the segmented guide rail traversing mode is adopted, the guide rail 2 is distributed on the bar seat 1 at a certain interval, and the bar 3 is moved laterally in the guide rail 2, and the bar is directly driven by the servo motor to move laterally, each The traverse amount of the bar is set by pattern program and controlled by computer. The guide needles are detachably fixed on the bar. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com