Hollow fiber ultra-filtration membrane assembly having improved central conduit structure

A central catheter and ultrafiltration membrane technology, which is applied in the field of ultrafiltration membranes, can solve the problems of poor water output and achieve the effect of increased water flow rate and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

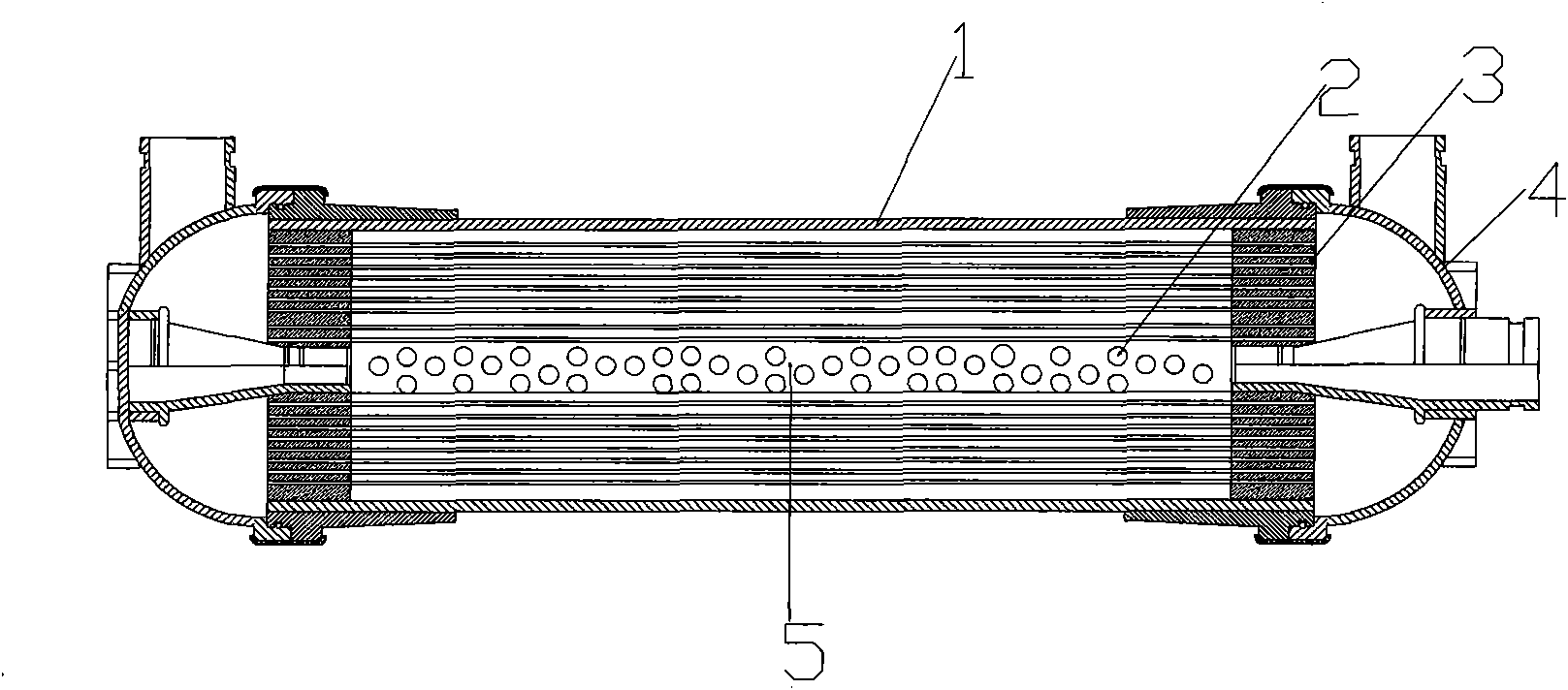

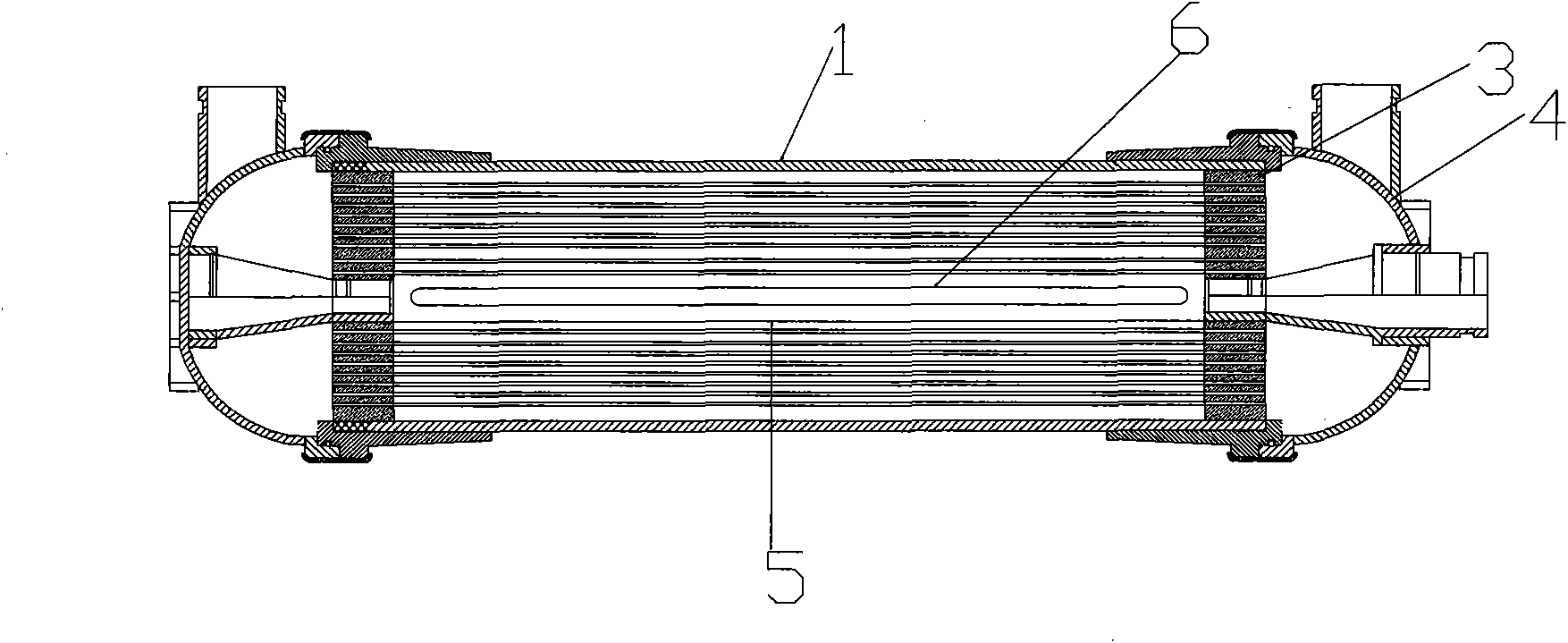

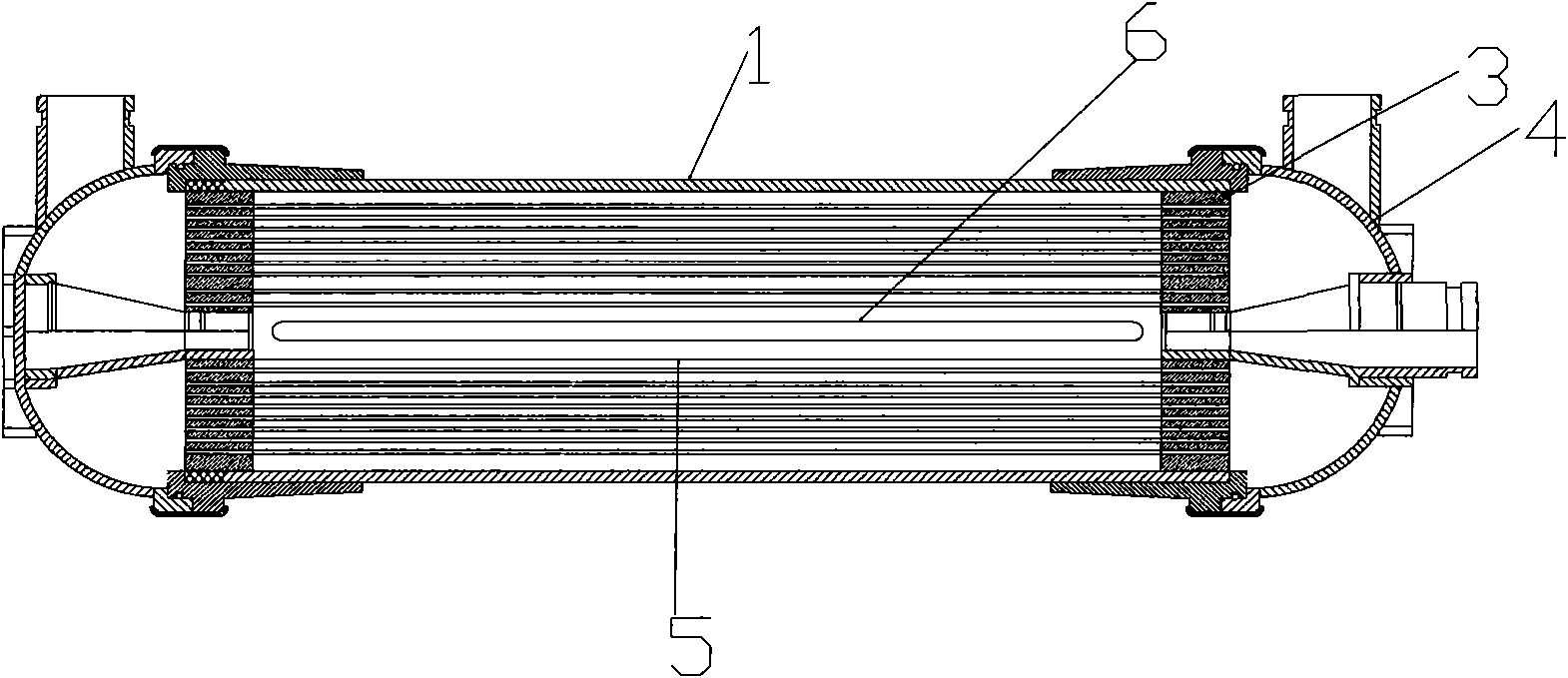

[0010] Such as figure 2 As shown, it is a hollow fiber ultrafiltration membrane module with an improved central conduit structure, and the hollow fiber ultrafiltration membrane is composed of a pressure-bearing housing 1, a sealant 3, an end cover 4, a central conduit 5, and a strip hole 6 composition.

[0011] The two ends of the pressure-bearing shell 1 are provided with end caps 4, the center of the pressure-bearing shell 1 is provided with a central conduit 5 along the axial direction, and an ultrafiltration membrane is arranged between the central conduit 5 and the inner wall of the pressure-bearing shell 1, and the two ends of the ultrafiltration membrane A sealant 3 is provided, and the feature is that the central conduit 5 is provided with a strip-shaped hole 6 .

[0012] When in use, after the raw water enters from the central conduit 5, the water exits from the elongated hole 6, and the flow rate of the exiting water is increased, and it is also easier to clean the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com