Low-noise rotor chamber for a centrifuge

一种离心机转子、转子腔的技术,应用在离心机领域,能够解决离心机噪声高、恼人等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

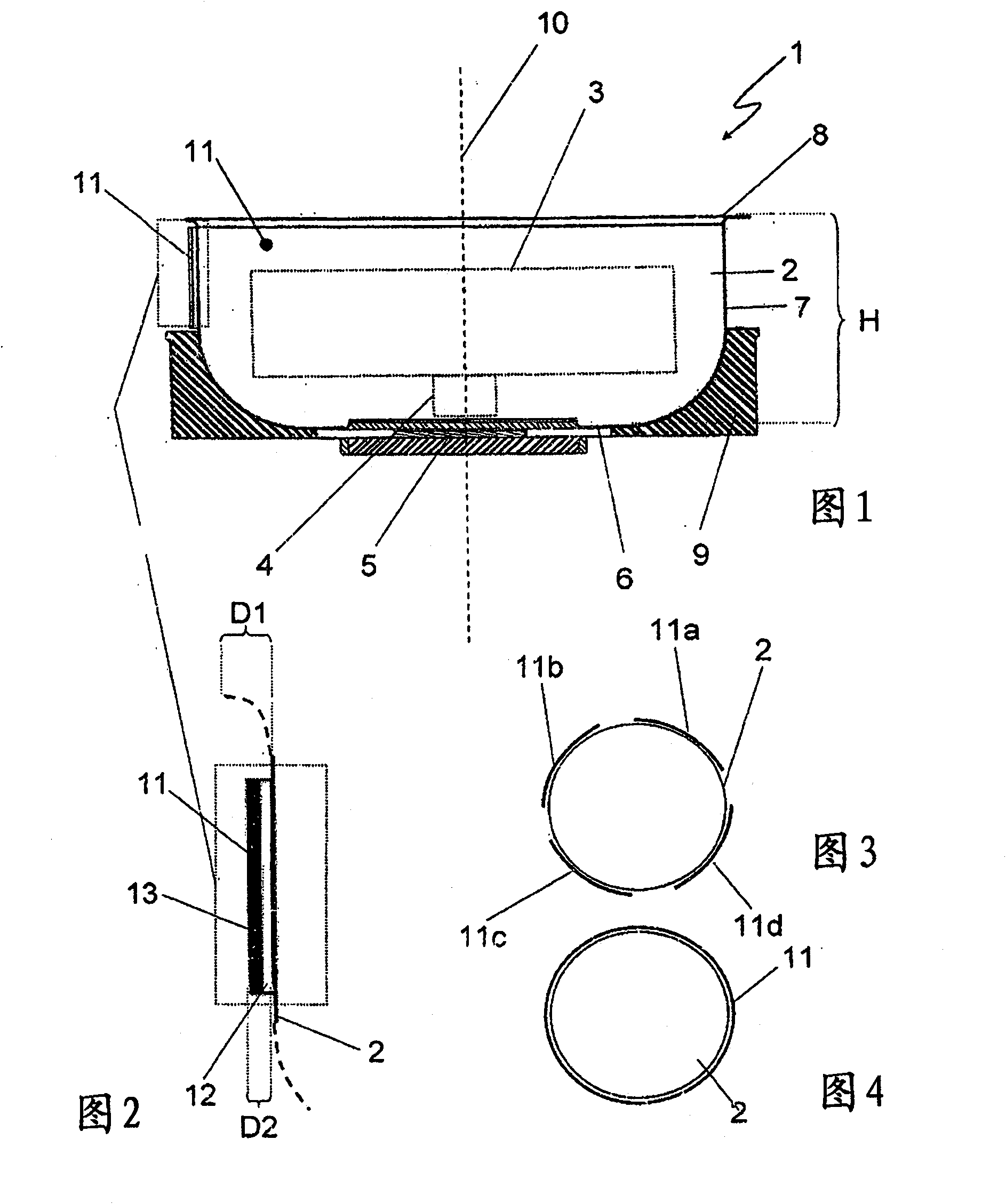

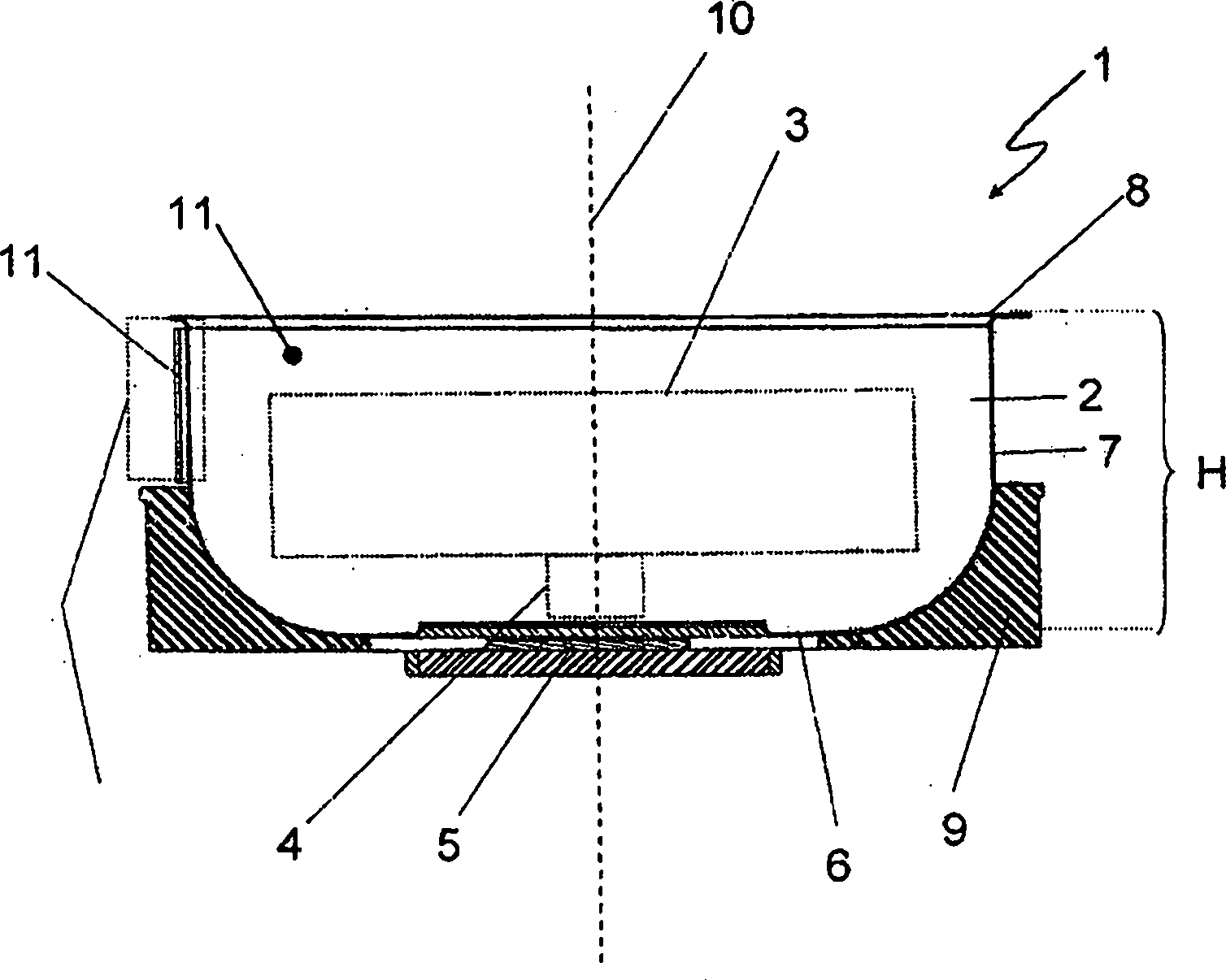

[0035] In the illustrated embodiment, the same parts are provided with the same reference signs hereinafter.

[0036] exist figure 1 The centrifuge 1 is only partially shown in the figure, which comprises a rotor chamber 2 in a housing (not shown), the rotor chamber 2 is provided with a rotor chamber interior 2a for receiving a rotor 3 (in particular a pair of oscillating Outer rotor), the rotor 3 is connected to the motor element 5 via a drive shaft 4 . The rotor chamber 2 also comprises a flat base area 6 , a wall area 7 adjoining on top of the base area and an upper edge area 8 . The rotor chamber 2 is designed to be open at the top, and the outside is covered by a cover (not shown) during operation. Furthermore, in the lower region, the rotor chamber 2 is accommodated in a groove-shaped foam molding 9 which protrudes from the base region 6 by up to half the height H of the rotor chamber 2 . The damping lining 11 adjoins the top of the foam-molded part 9 in the direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com