Zipper coating device

A coating device and zipper technology, applied in the field of mechanical equipment, can solve problems such as waste, and achieve the effects of convenient coating, uniform coating and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

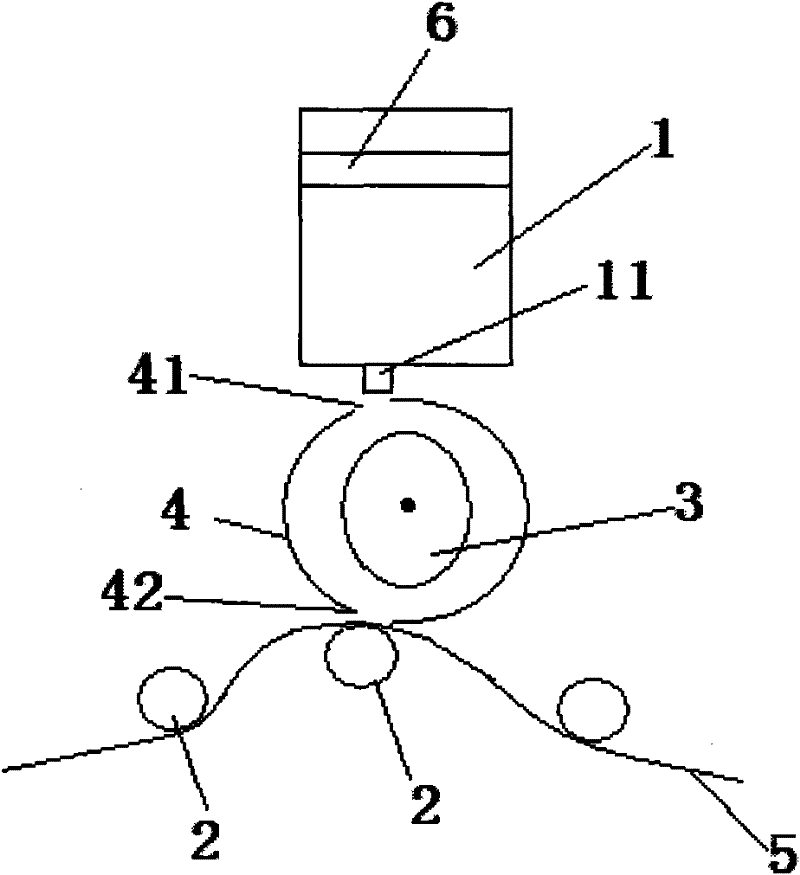

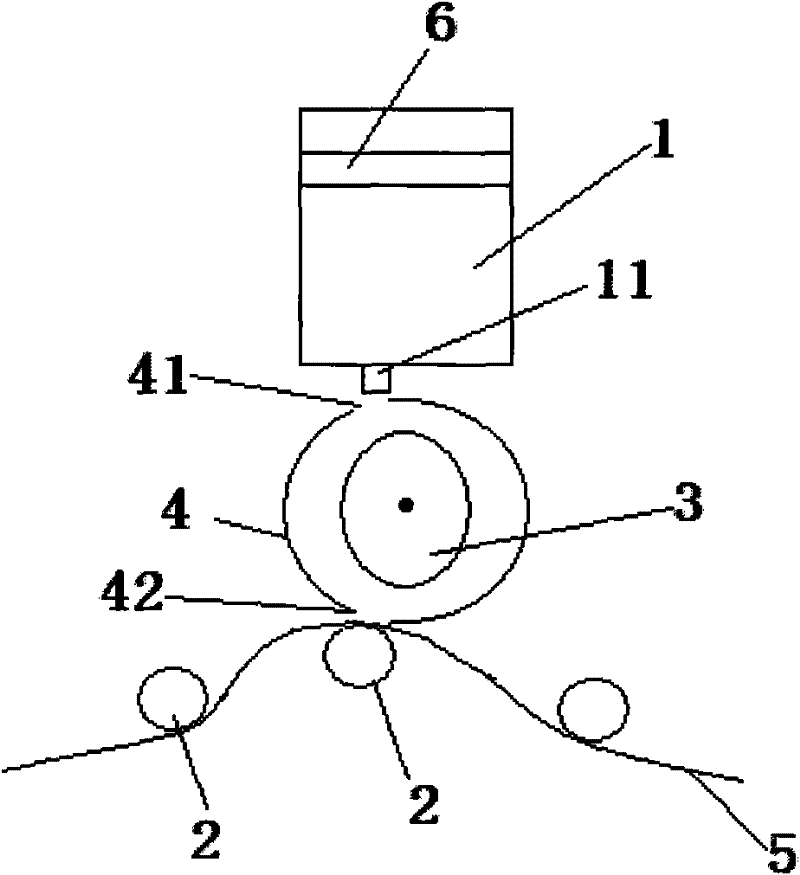

[0011] As shown in the drawings, a zipper coating device includes a material box 1, a roller 2 that guides the zipper 5 to travel, and a roller 3. The material box 1 is located above the device, and the bottom of the material box 1 is provided with a discharge Mouth 11, feed chute 4 is installed below discharge port 11, the top and bottom of described feed chute 4 are provided with feeding inlet 41 and coating port 42 respectively, are provided with roller coating wheel 3 inside feed chute 4; Below the trough 4, a roller 2 is arranged.

[0012] The material box 1 is placed on the top of the device, and the material box 1 can be set as a sealed tank-shaped structure through its own gravity or through mechanical pressure, and a piston-type material pressing device is arranged inside it. The protective paint or hot melt adhesive in the material box 1 can flow into the material tank 4 automatically or through the piston pressing device, and the roller coating wheel 3 in the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com