Elbow pipe piece forming machine

A technology for forming machines and pipe fittings, applied in the field of elbow pipe fittings forming machines, can solve the problems affecting the appearance, strength, and troublesome operation of bending pipe fittings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

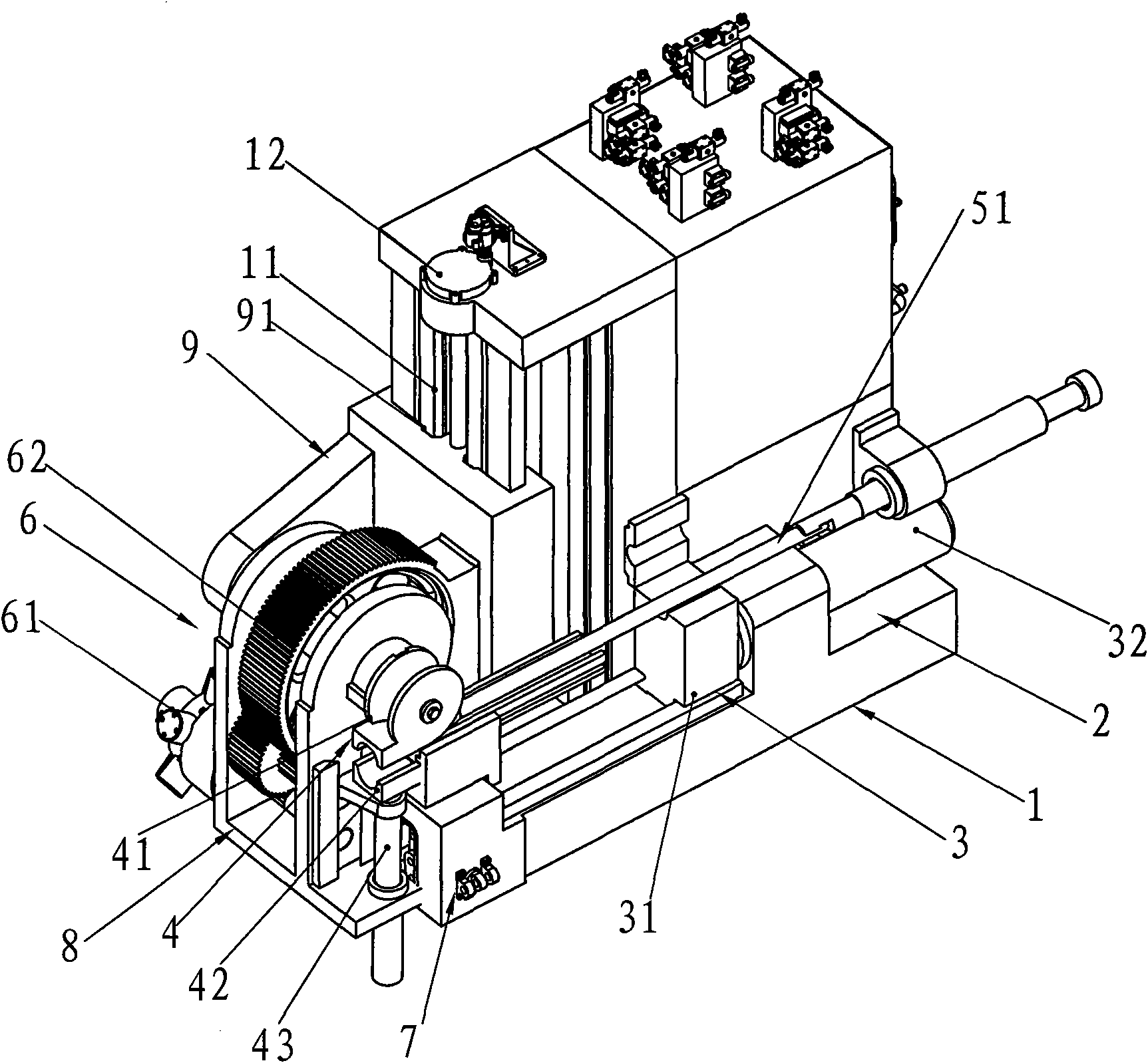

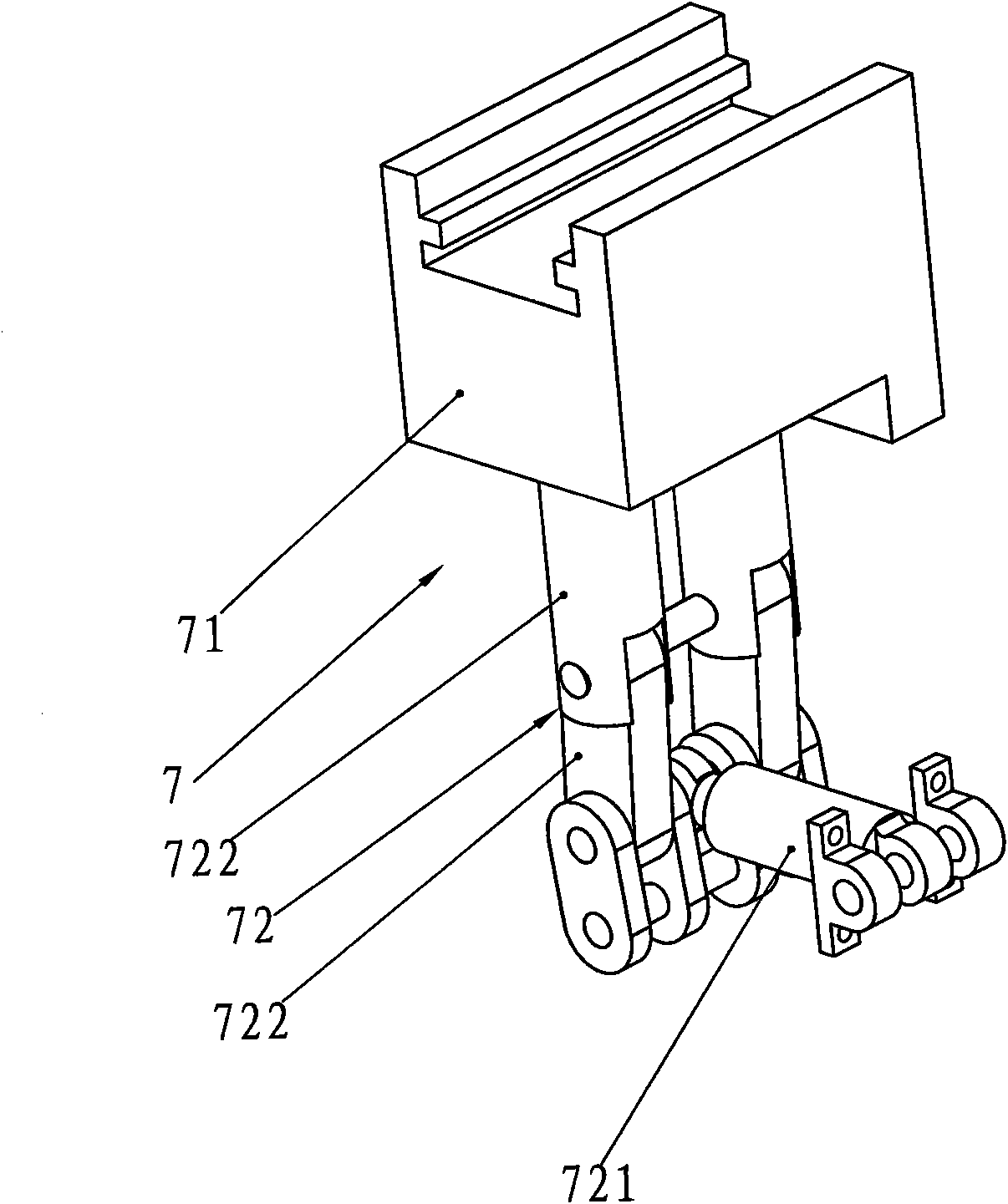

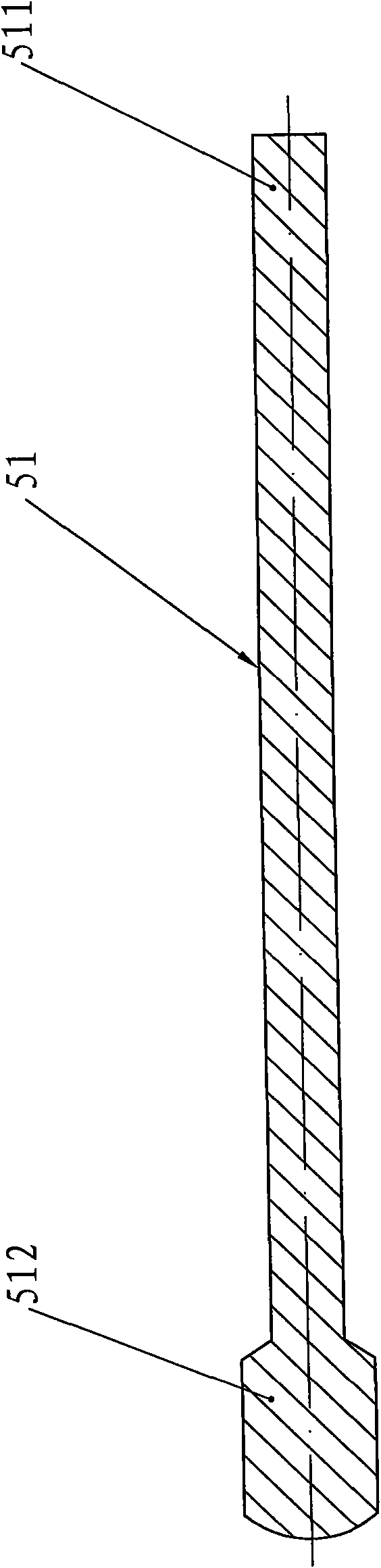

[0016] Such as Figure 1-Figure 3 The shown elbow pipe fitting forming machine includes a body 1, a workbench 2 arranged on the body 1, a pusher mechanism 3 arranged on the workbench 2, a bending mechanism 4 connected with the pusher mechanism 3, a core The rod 51, the mandrel positioning mechanism 5 and the driving mechanism 6 for driving the bending mechanism 4; The propulsion cylinder 32 that slides along the workbench; the bending mechanism 4 includes a bending die 41 and a die clamping block 42 corresponding to the bending die 41, and the end face of the bending die 41 opposite to the die clamping block 42 is the The arc-shaped clamping groove 43 adapted to the surface, the mold clamp block 42 and the bending mold 41 rotate synchronously, the mandrel 51 includes a sleeve end 511 and an expansion end 512, and the diameter of the expansion end 512 of the mandrel 51 is larger than the sleeve end. 511, its sleeve end 511 is an end that conflicts with the mandrel positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com