Moulding die with movable drawing rib and solid particle medium radial thrust

A technology of radial thrust and granular media, which is applied in the field of stamping dies, can solve the problems of inability to change the resistance of variable drawbeads without radial thrust and the sealing of deep drawing dies, and achieve the advantages of large adjustment, convenient maintenance, and improved product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

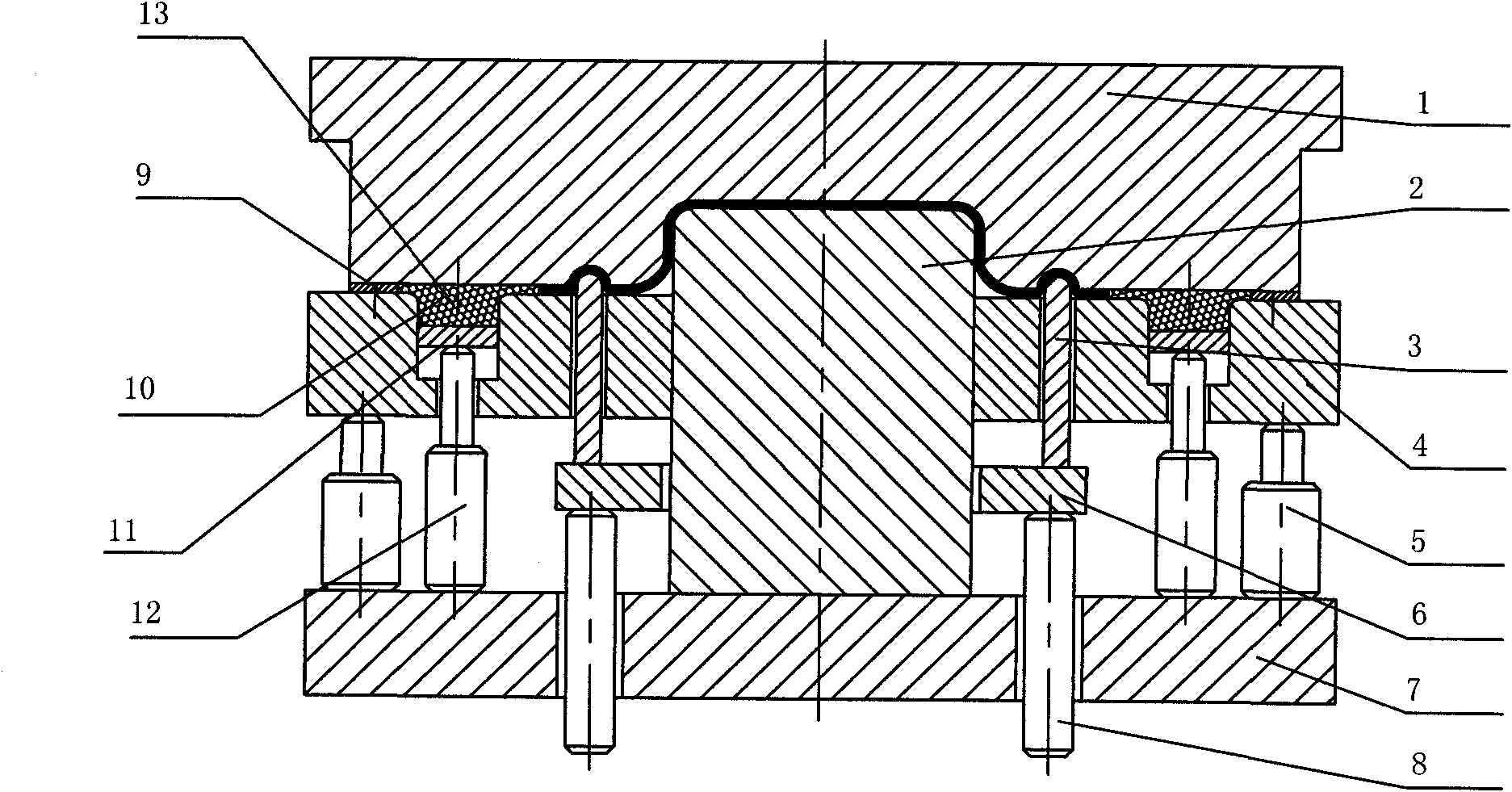

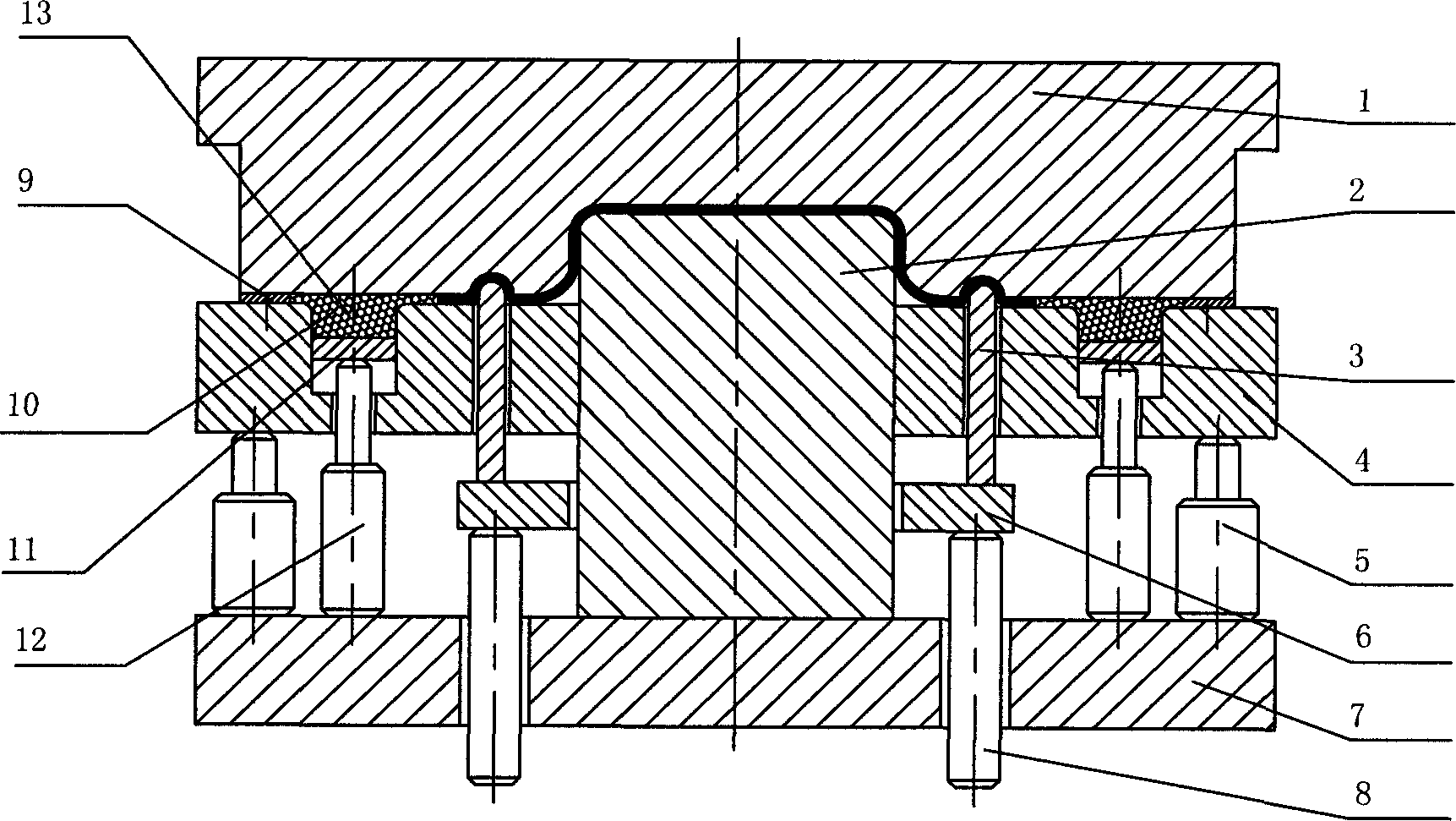

[0014] see figure 1 , shows the forming die with movable drawbead and radial thrust of the present invention, including upper die 1, punch 2, drawbead 3, binder plate 4, compression nitrogen cylinder 5, backing plate 6, lower die Seat 7, ejector pin 8, sealing plate 9, solid particle 10, top plate 11 and top material nitrogen cylinder 12; Upper mold 1 is installed on the inner slide block (not shown in the figure), and upper mold 1 is usually a die; Convex Die 2 is installed on the lower mold base 7, usually a punch as the lower die. Compression nitrogen cylinder 5 and top material nitrogen cylinder 12 are also installed on the lower mold base 7, the working end of compression nitrogen cylinder 5 is in contact with the lower surface of binder plate 4, and withstands the lower surface of binder plate 4; The cylinder 5 provides the required pressing force of the pressing plate 4 . The working end of the top material nitrogen cylinder 12 passes through the binder plate 4, conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com