Manufacturing method of super thin bidirectional stretched polypropylene coarse thin film for capacitor

A technology of biaxial stretching and manufacturing method, used in applications, household appliances, flat products, etc., can solve the problems of poor product quality and performance, difficult to meet the breakdown voltage of power capacitors, and electrical weaknesses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

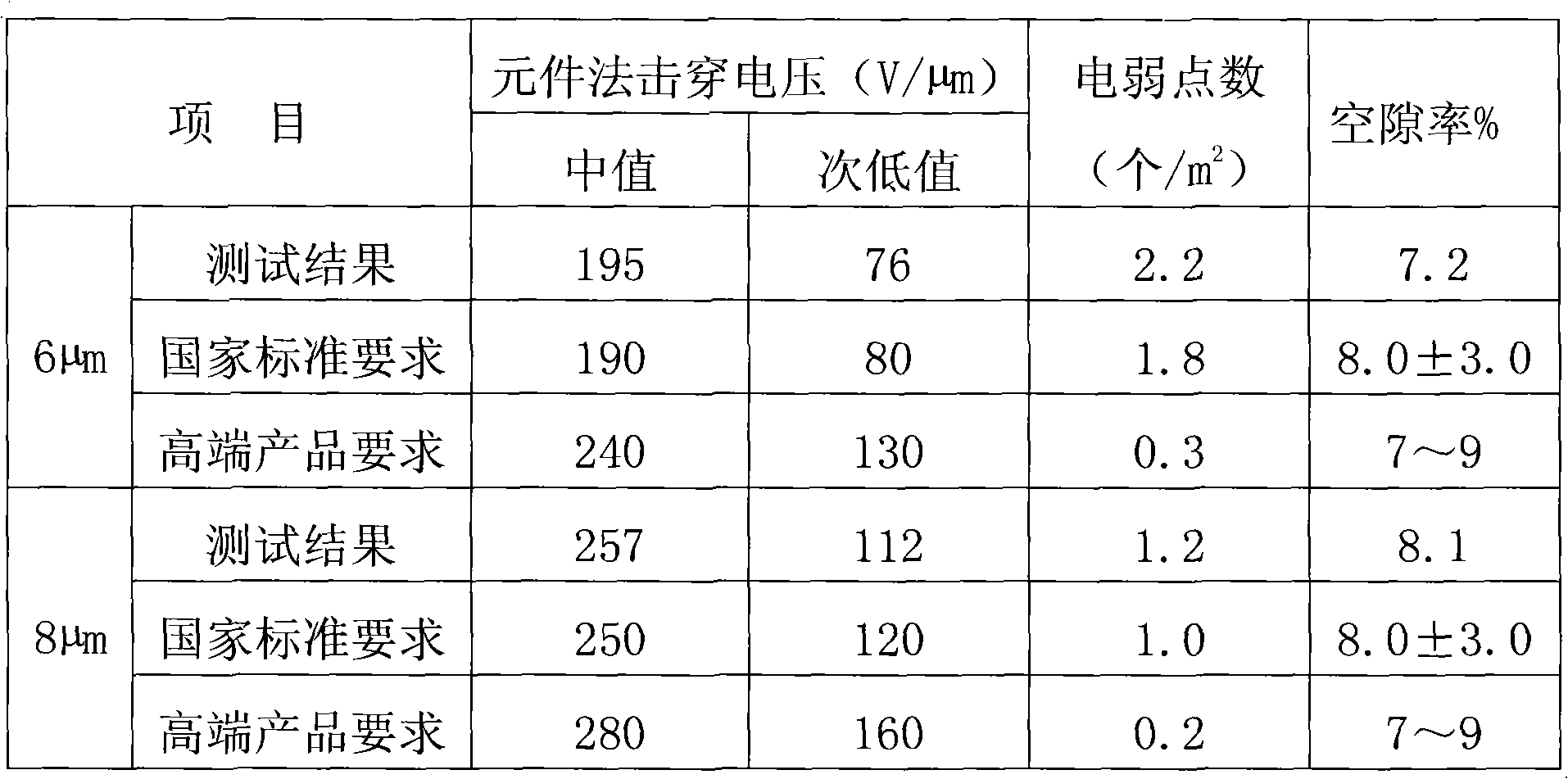

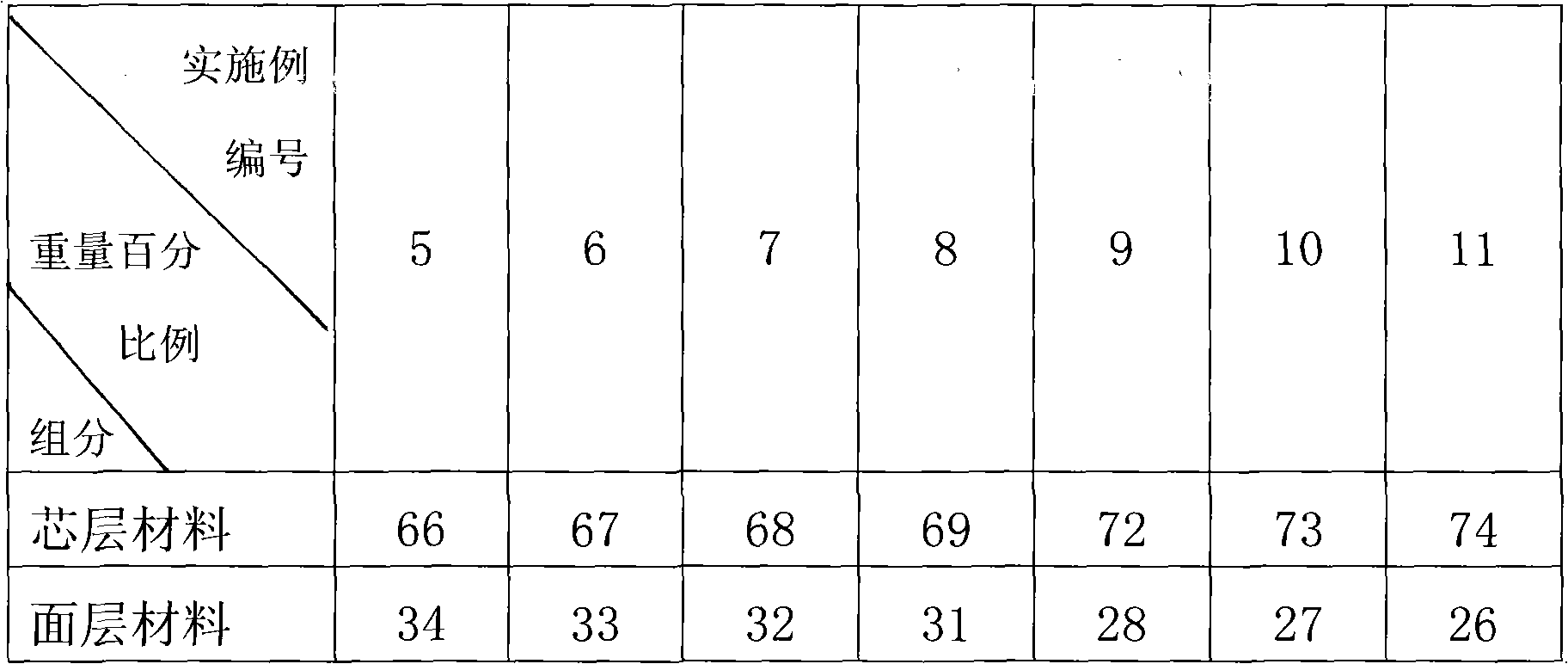

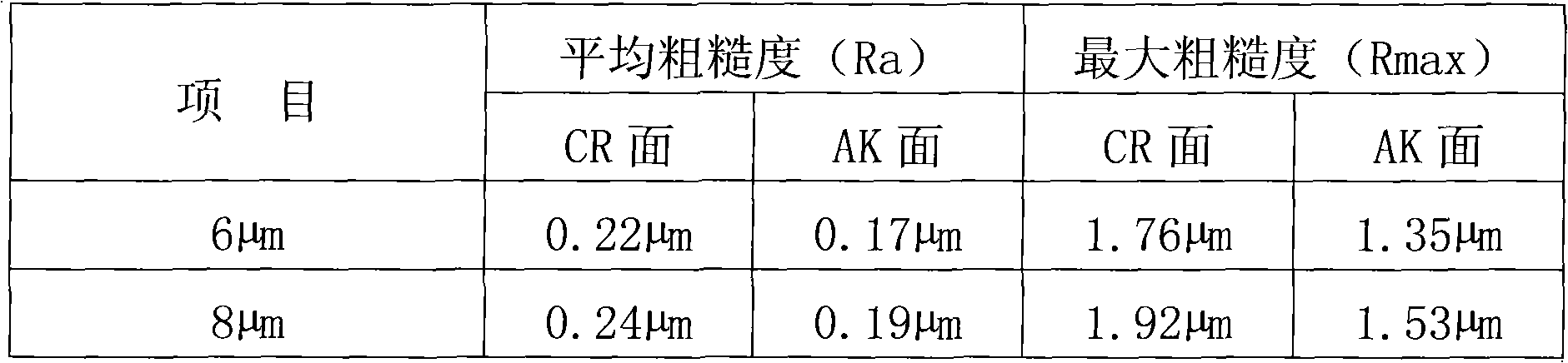

[0025] A method for manufacturing an ultra-thin biaxially oriented polypropylene roughened film for capacitors, comprising the following steps:

[0026] (1) The method of mixing and co-extruding with three-layer composite die head, main extruder and auxiliary extruder; using two kinds of special thickeners for electrical grade with an isotacticity of 95% to 98%, an ash content of less than 30ppm, and a different melt index. Polypropylene resin material; core layer material melt index is 2.5g / 10min~3.2g / 10min, extrusion ratio is 65%~75%, extruded by main extruder, extrusion temperature is 230℃~250℃; The melt index of the surface layer material is 3.5g / 10min~4.2g / 10min, the extrusion ratio is 25%~35%, extruded by the auxiliary extruder, and the extrusion temperature is 210℃~230℃;

[0027] (2) When the melt is cooled, the temperature of the cooling roll is controlled at 95°C to 105°C. At the same time, when the melt is attached to the cooling roll, the back side is cooled by a he...

Embodiment 2

[0030] A method for manufacturing an ultra-thin biaxially oriented polypropylene roughened film for capacitors, comprising the following steps:

[0031] a. Ingredients: The ingredients are formulated according to the weight percentage of 65% of the core layer material and 35% of the surface layer material. The core layer material adopts an isotacticity of 95% to 98%, an ash content of less than 30ppm, and a melt index of 2.5g / 10min to 3.2 g / 10min polypropylene resin material (manufacturers include Borealis HC312BF, Japan Mitsui Chemicals F104A-1, etc., and other embodiments can be the same), and the surface layer material adopts an isotacticity of 95% to 98%, an ash content of less than 30ppm, A polypropylene resin material with a melt index of 3.5g / 10min to 4.2g / 10min (manufacturers include Borealis HC314BF, Mitsui Chemicals F104A, etc., and other embodiments can be the same);

[0032] b. Melt extrusion: the core layer material and the surface layer material are melted by the...

Embodiment 3

[0037] A method for manufacturing an ultra-thin biaxially oriented polypropylene roughened film for capacitors, comprising the following steps:

[0038] a. Ingredients: The ingredients are formulated according to the weight percentage of 75% of the core layer material and 25% of the surface layer material. The core layer material adopts an isotacticity of 95% to 98%, an ash content of less than 30ppm, and a melt index of 2.5g / 10min to 3.2 g / 10min polypropylene resin material, the surface layer material adopts a polypropylene resin material with an isotacticity of 95% to 98%, an ash content of less than 30ppm, and a melt index of 3.5g / 10min to 4.2g / 10min; the core layer The materials and surface materials are all electrical grade special polypropylene resin materials;

[0039] b. Melt extrusion: the core layer material and the surface layer material are melted by the main and auxiliary double extruders at the same time, and then extruded through the auxiliary-main-auxiliary thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com