Surface grafting polar monomer modified polystyrene macroporous resin and preparation method thereof

A polystyrene type, polar monomer technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low grafting rate, a large number of processing restrictions, etc., achieve simple reaction steps, improve surface properties, The effect of overcoming pore blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

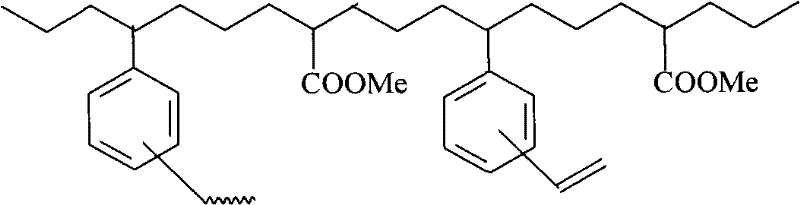

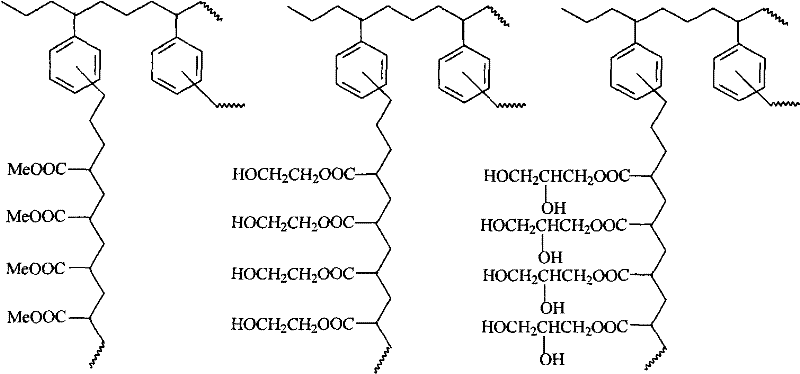

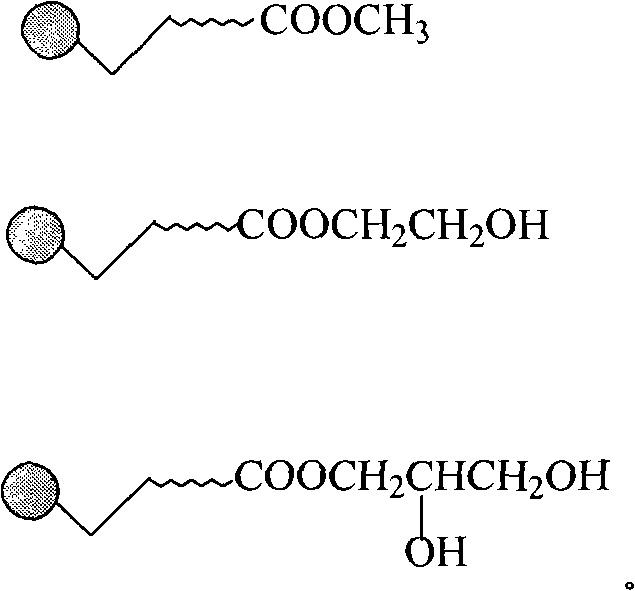

Method used

Image

Examples

Embodiment 1

[0039] Add 800 g of deionized water and 8.0 g of gelatin to a 2000 mL three-necked flask equipped with a stirrer, a reflux condenser, and a thermometer, soak overnight, heat the water bath to 45°C the next day, and prepare the pre-prepared oil phase (monomer Industrial divinylbenzene 100g content is 55%, mixed with 125ml porogen toluene, initiator BPO 1.0g) add, adjust the stirring speed, after the organic phase is dispersed into oil droplets with appropriate particle size, the temperature is raised at 1°C / 2min Slowly raise the temperature to 78°C for 2 hours, then raise the temperature to 85°C for 3 hours, then raise the temperature to 90°C for 6 hours, then stop the reaction. Filter out the resin with a gauze bag while it is hot, wash the resin with a large amount of hot water until the water is clear, wash with acetone, extract with acetone in a Soxhlet extractor for 8 hours, dry it in vacuum at 60°C, and sieve for 30-60 Mesh pellets are ready for use.

[0040] In a 100ml ...

Embodiment 2

[0042] According to the same method of embodiment 1, the grafting monomer is hydroxyethyl methacrylate. A modified resin containing a hydroxyl group and an ester group on the surface is obtained.

Embodiment 3

[0044] According to the same method as in Example 1, the grafted monomer is glycidyl methacrylate to obtain a grafted resin, which is swollen with 5 volumes of tetrahydrofuran for 1 hour, then added with 1M sulfuric acid aqueous solution, stirred and reacted at 50°C for 2 hours, filtered The resin is discharged, and the water is repeatedly washed until the effluent water is neutral to obtain a modified resin containing dihydroxy and ester groups.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com