High-strength water-retaining perfluorosulfonic acid proton exchange membrane as well as preparation method and application thereof

A proton exchange membrane and perfluorosulfonic acid technology, applied in fuel cells, electrochemical generators, electrical components, etc., can solve the problems of weak interface binding force, poor durability and stability, and disadvantages, and achieve low porosity , long service life, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

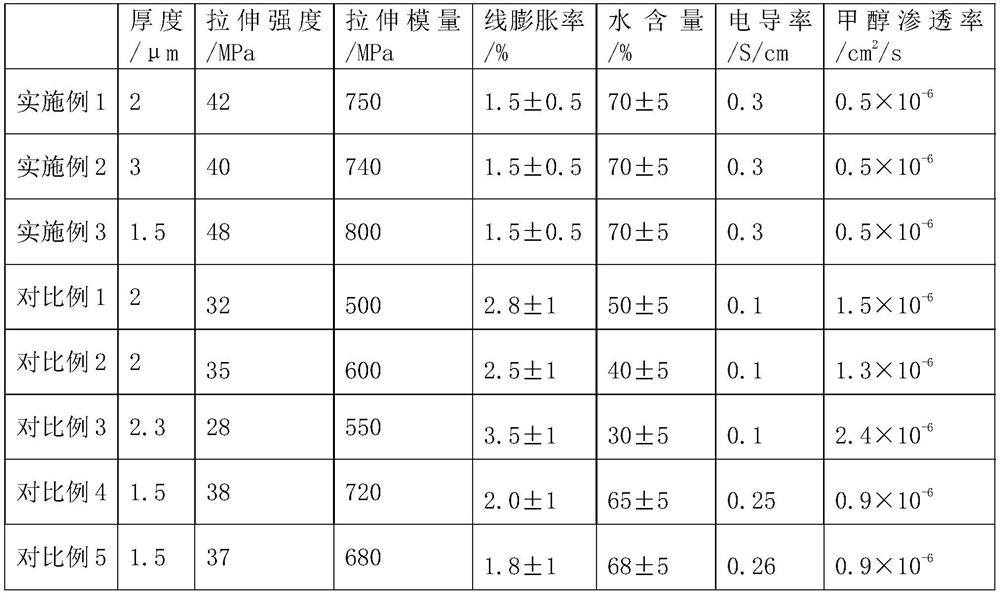

Examples

preparation example Construction

[0015] First illustrate the preparation method according to the high-intensity water-retaining perfluorosulfonic acid proton exchange membrane of the first aspect of the present invention, it comprises the following steps: (1) prepare functionalized graphene: by mass ratio 10:(1~3):20: 0.2 Weigh graphene oxide, lactic acid monomer, deionized water and stannous octoate into the autoclave, pressurize and heat at 100-120°C, pressure 1-2Mpa, time 4-10h, then naturally cool to 40- 60°C, filtered, and washed with deionized water to obtain lactic acid functionalized graphene oxide; (2) Preparation of perfluorosulfonic acid resin modified material: end with -SO 3 The mixed aqueous solution of Na perfluorosulfonic acid resin and polyvinyl alcohol is heated to 95-100°C, and the above-mentioned lactic acid functionalized graphene oxide is added according to the mass ratio of the aqueous solution to 5-20%, stirred evenly, and pressurized in the autoclave for 1.5- Heat at 2Mpa at 105-120°C...

Embodiment 1

[0020] The preparation method of high-strength water-retaining perfluorosulfonic acid proton exchange membrane is as follows: (1) Preparation of functionalized graphene: by mass ratio 10:1:20:0.2, weigh graphene oxide, lactic acid monomer, deionized water and octanoic acid Put stannous into the autoclave, pressurize and heat, temperature 100°C, pressure 1Mpa, time 4h, then naturally cool to 40°C, filter, and wash with deionized water once to obtain lactic acid functionalized graphene oxide; (2) perfluorinated Sulfonic acid resin modified material: with -SO at the end 3 The mixed aqueous solution of Na perfluorosulfonic acid resin and polyvinyl alcohol is heated to 95°C, and the mass ratio of the aqueous solution is 5%, and the above-mentioned lactic acid functionalized graphene oxide is added, stirred evenly, heated to 105°C under pressure of 1Mpa, kept for 2h, and stirred Heating and drying under normal pressure to obtain modified perfluorosulfonic acid resin; 3 The concentr...

Embodiment 2

[0022] The preparation method of high-strength water-retaining perfluorosulfonic acid proton exchange membrane is as follows: (1) Preparation of functionalized graphene: according to the mass ratio of 10:3:20:0.2, weigh sulfonated graphene oxide, lactic acid monomer, deionized Add water and stannous octoate into the autoclave, pressurize and heat, temperature 120°C, pressure 2Mpa, time 10h, then naturally cool to 60°C, filter, and wash with deionized water for 5 times to obtain lactic acid functionalized sulfonated graphene; ( 2) Perfluorosulfonic acid resin modified material: with -SO at the end 3 The mixed aqueous solution of Na perfluorosulfonic acid resin and polyvinyl alcohol is heated to 100°C, and the mass ratio of the aqueous solution is 20%, the above-mentioned lactic acid functionalized sulfonated graphene is added, stirred evenly, heated to 120°C under pressure at 2MPa, and kept for 10h, Heating and drying under normal pressure under stirring conditions to obtain pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com