Fabric noniron finishing method, continuous fabric pressing device and press finishing machine

A finishing machine and pressure device technology, which is applied to washing devices, ironing machines, textiles and papermaking, etc., can solve problems such as poor flatness and poor wrinkle resistance, and achieve the effect of reducing internal stress and improving anti-wrinkle and non-ironing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

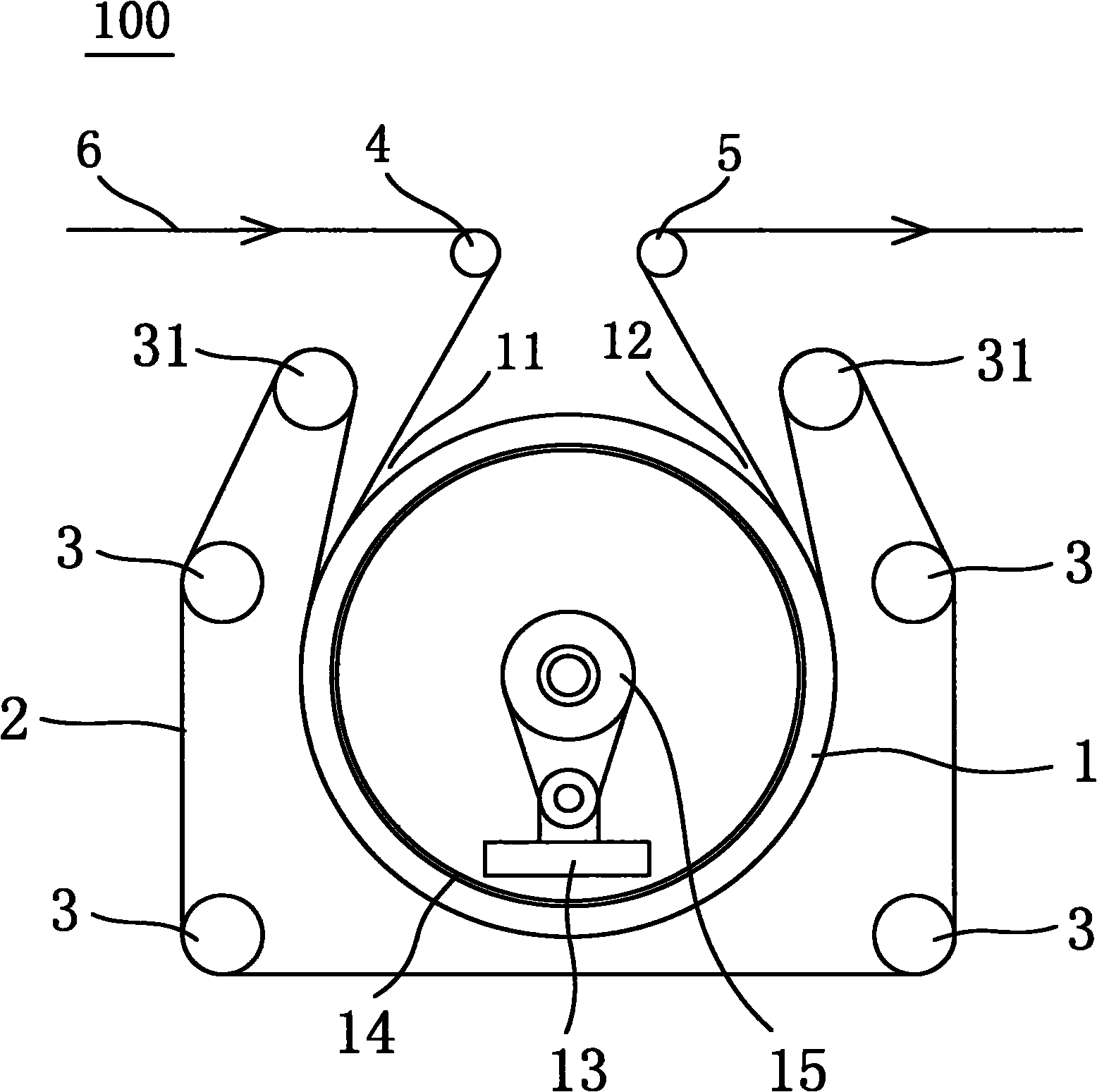

[0051] Please refer to figure 1 , is a schematic structural diagram of a continuous fabric pressing device according to the first embodiment of the present invention. As shown in the figure, the pressing device 100 of the present invention mainly includes: a pressing roller 1, a covering blanket 2, a supporting guide roller 3, a cloth feeding The guide roller 4 and the cloth outlet guide roller 5, wherein the pressing roller 1 is mainly used for pressing the fabric 6, and the covering blanket 2 is connected end to end to form a closed ring, which is closely attached to the roller surface of the pressing roller 1 and covered The covering blanket 2 is tightened by the supporting guide roller 3 arranged around the pressing roller 1 to ensure the tightness between the covering blanket 2 and the pressing roller 1. The fabric 6 is sandwiched between the roller surface of the pressing roller 1 and the coating Between the blankets 2, and at the cloth inlet end and the cloth outlet end...

no. 2 example

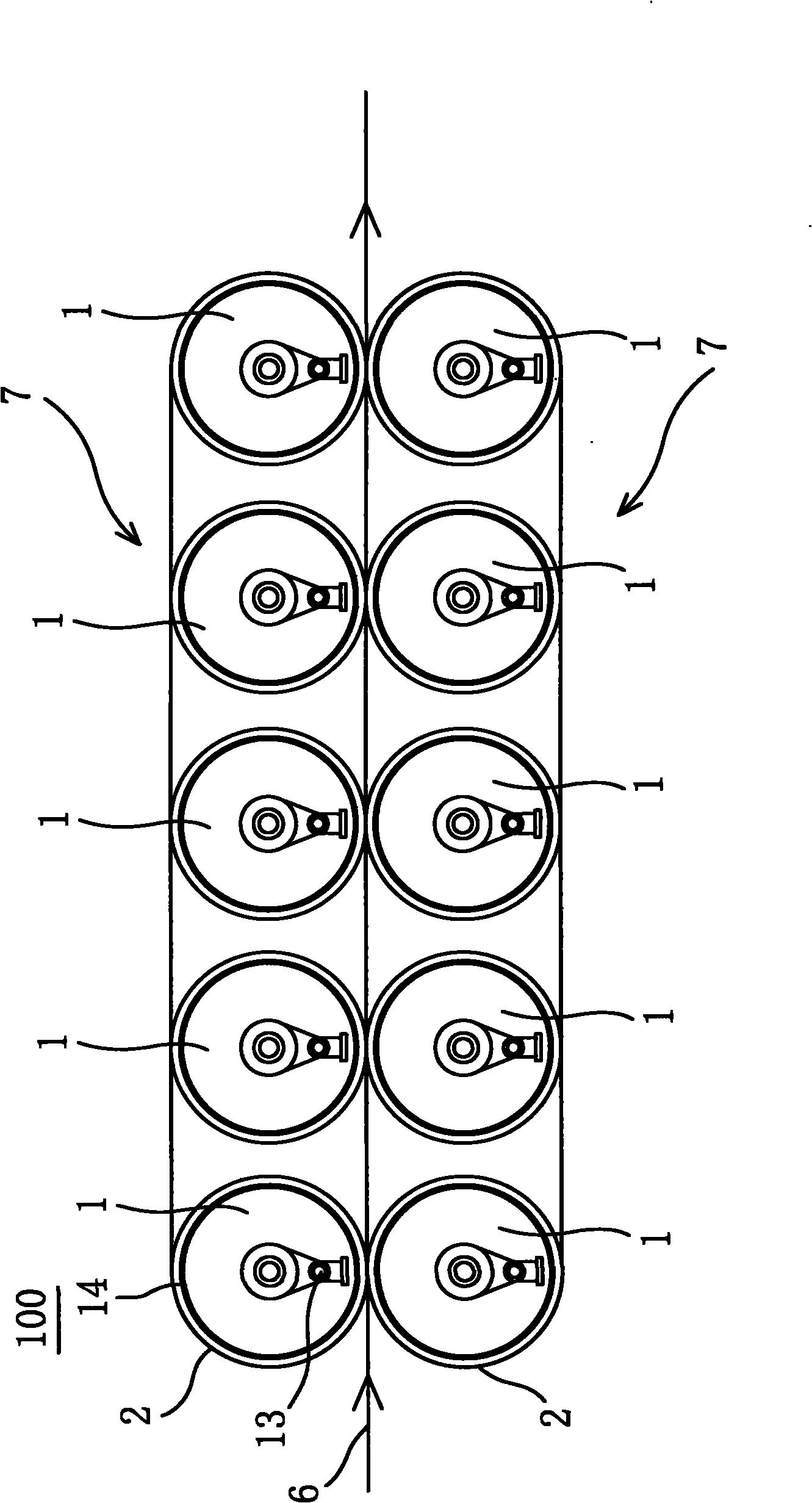

[0058] Please refer to figure 2 , is a schematic structural diagram of the continuous fabric pressing device of the second embodiment of the present invention, as shown in the figure, compared with the above-mentioned first embodiment, in this embodiment, the pressing roller track group 7 is used to replace the first embodiment Pressing rollers in the fabric 6 are used to press the fabric 6. In this embodiment, the pressing device 100 mainly includes two sets of pressing roller track groups 7, and each group of pressing roller track groups 7 includes a plurality of pressing rollers 1 In this embodiment, each set of pressing roller crawler tracks 7 includes five pressing rollers 1, but it is not limited thereto. A plurality of pressing rollers 1 have the same specification and size and are parallel and arranged in a row, wherein at least one pressing roller 1 is connected to the driving device and can be driven to rotate. Preferably, each pressing roller 1 is provided with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com