Piston assembly of air compressor

A technology of air compressor and piston assembly, which is applied in the direction of pump components, mechanical equipment, variable displacement pump components, etc., and can solve the problem of poor anti-loosening ability of the sealing ring 3

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with specific embodiment, see Figure 4-12 :

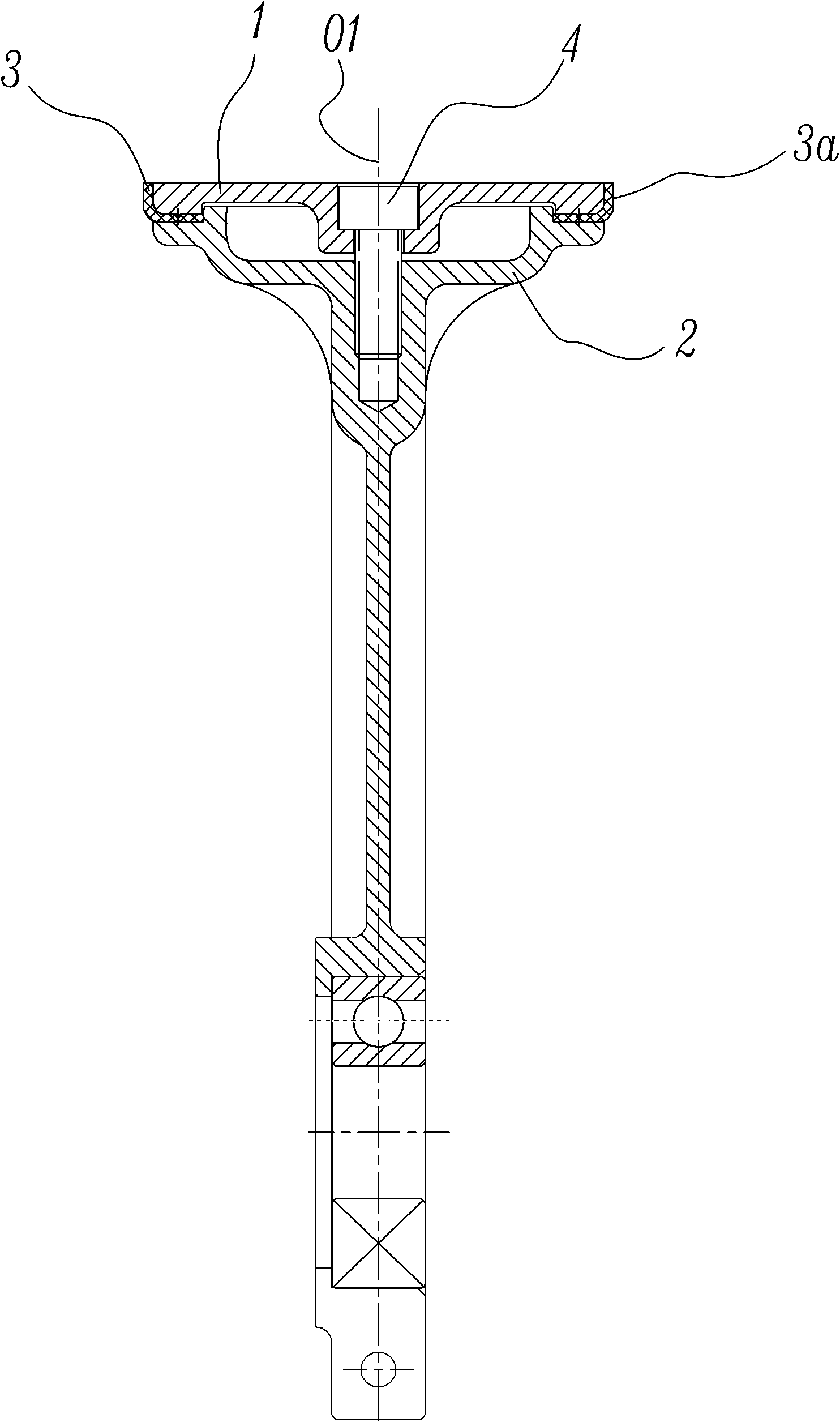

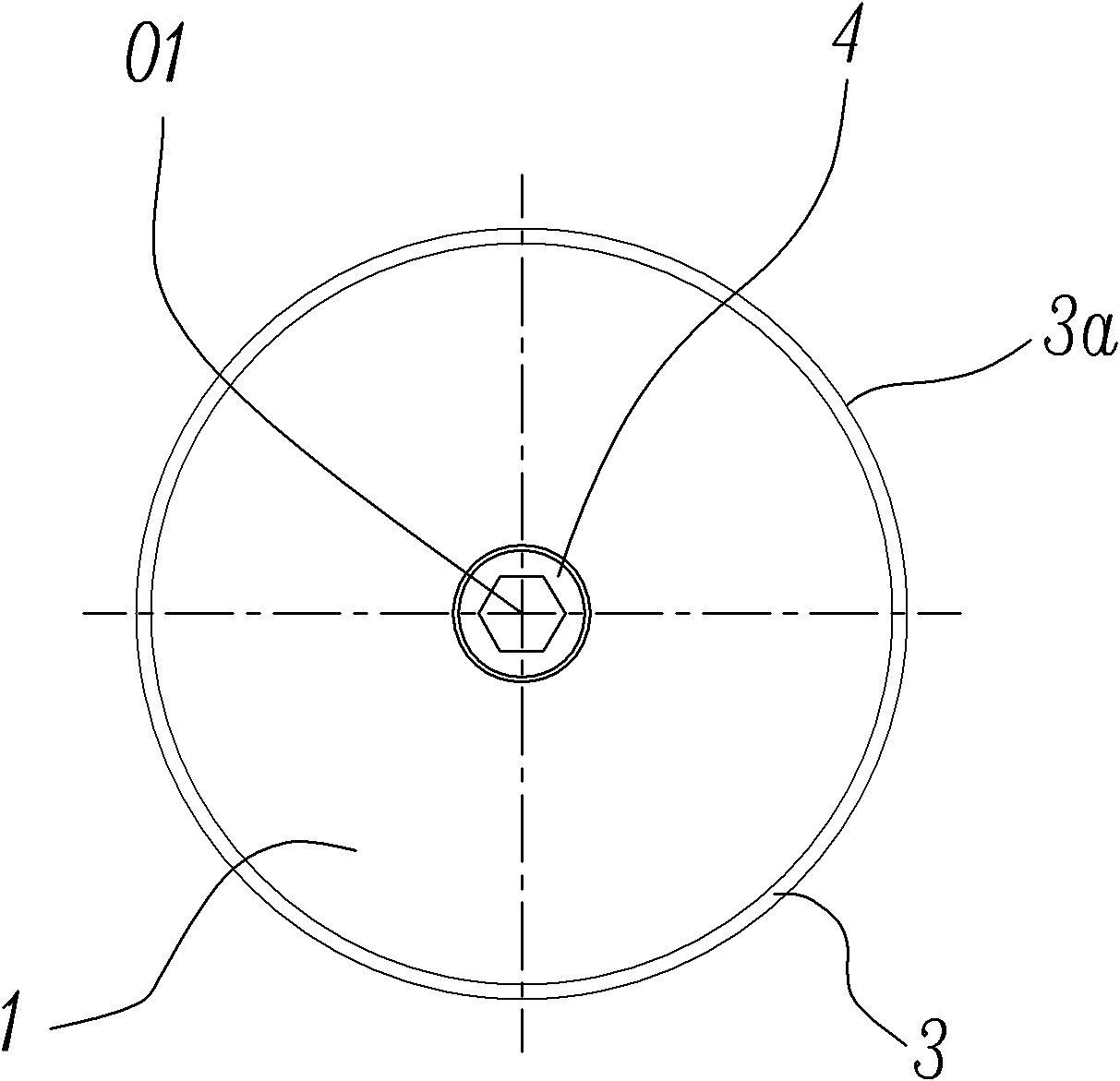

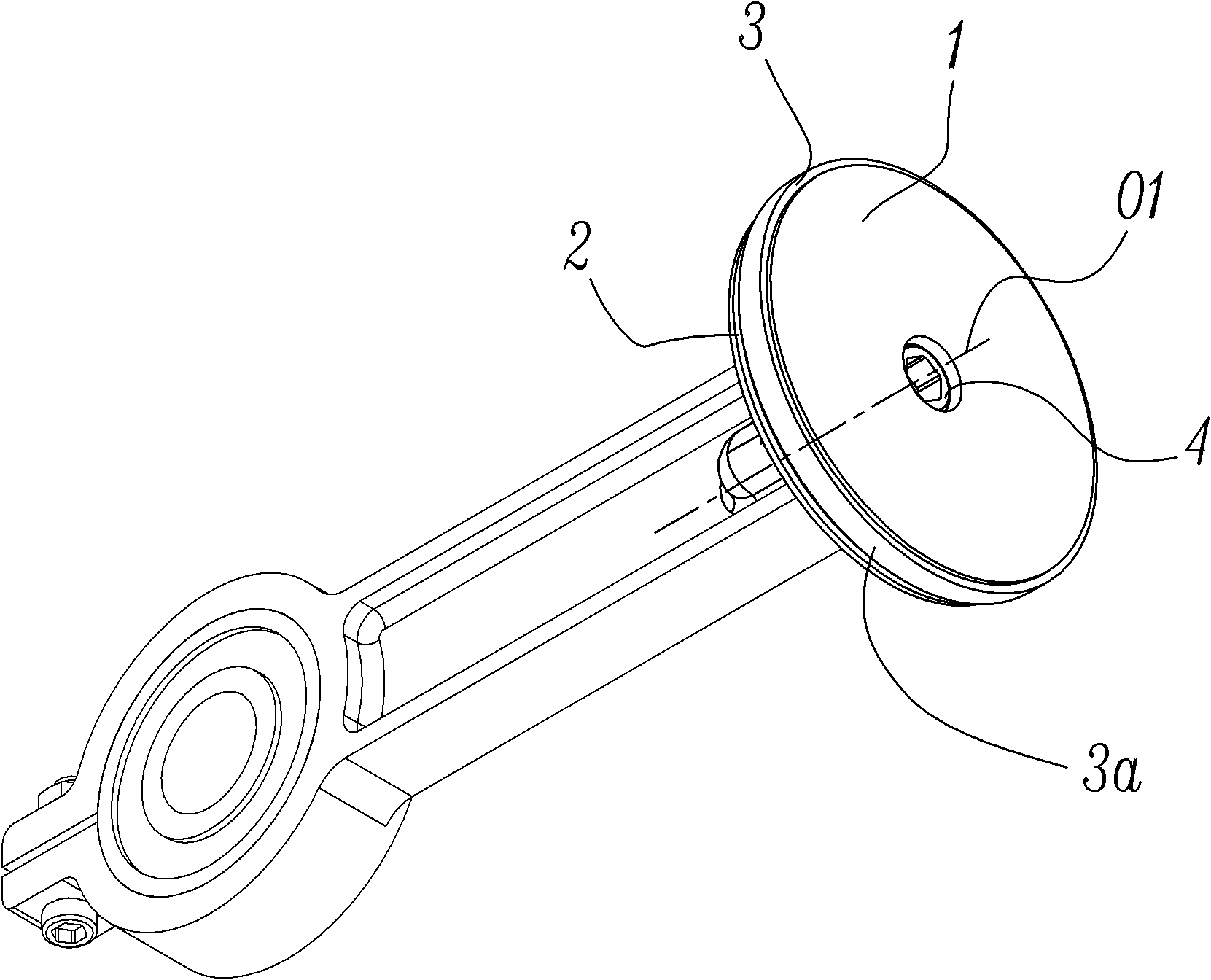

[0027] An air compressor piston assembly, which includes a piston cover plate 1, a piston body 2 and a sealing ring 3, the piston cover plate 1 is fastened to the piston body 2 using fasteners 4, the piston body 2 and the compression The connecting rod of the machine is tightly connected or made in one piece. In addition, the piston body 2 can also be connected with the connecting rod through a bearing or a pivot pin structure; the sealing ring 3 is fitted between the piston cover plate 1 and the piston body 2, and the sealing ring A part of 3 can be bent and rolled up to be a cup shape and cover a part of the cover plate outer edge surface 1c of the piston cover plate 1 (from Figure 4 and Figure 8 It can be clearly seen from above), of course, the sealing ring 3 can also not cover the cover plate outer edge surface 1c of the piston cover plate 1; center and perpend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com