Packaging structure and method of quasi-distributed fiber grating temperature sensor

A temperature sensor and fiber grating technology, which is applied in the field of packaging structure of quasi-distributed fiber grating temperature sensor, can solve the problems of fiber grating temperature sensor damage and easy breaking, and achieves the effects of low cost, good repeatability and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The best embodiment of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

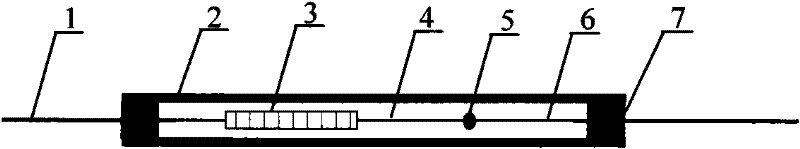

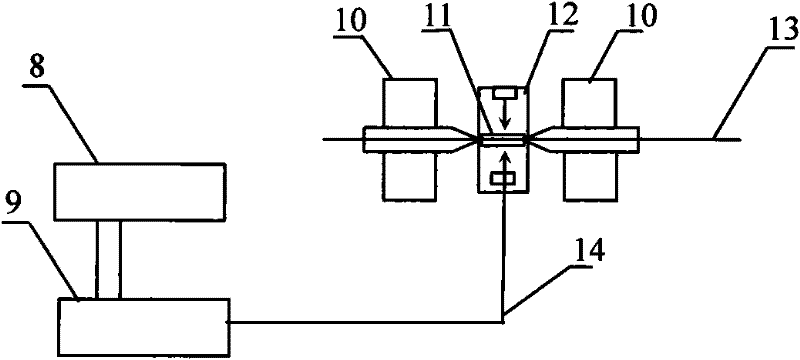

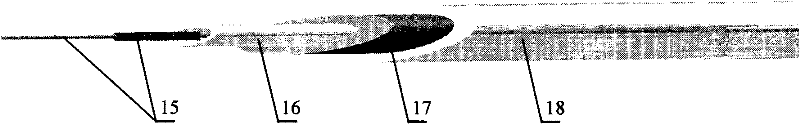

[0026] Single Fiber Bragg Grating Temperature Sensor Package (see figure 1 ) is as follows: (1) cutting a section of quartz glass capillary 2 that is 50-100mm in length, 130-150um in inner diameter, and 100-300um in wall thickness; (3) Remove the coating layer of the short pigtail section, and wipe it clean with pure water / alcohol; (5) Thread the quartz capillary 2 onto the long pigtail side 1 of the grating with the coating layer (6) cut the optical fiber at the short tail fiber side 4 with an optical fiber cutter, then put it on the fiber fusion splicer; (7) remove the long tail fiber side 6 of the next grating, cut the flat end face, and ( 6) The end face processed in the process is welded with an optical fiber fusion splicer to form a solder joint 5; (8) Return the quartz capillary 2 to the short tail fiber side 4 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com