Three-dimensional printing method

A three-dimensional printing and three-dimensional technology, applied in manufacturing tools, processing data acquisition/processing, additive manufacturing, etc., can solve the problems of material property differences, ink falling off, insufficient bonding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

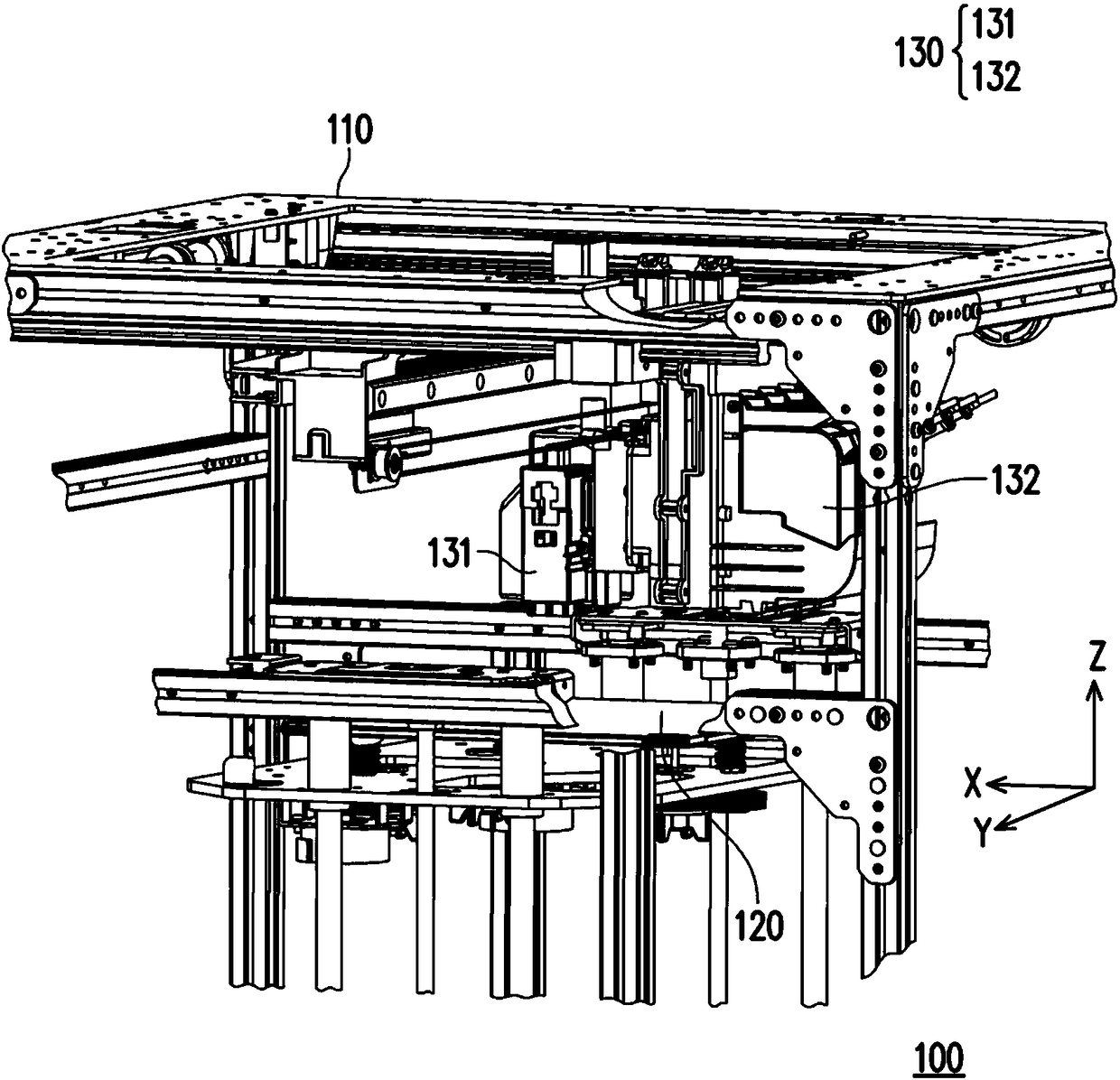

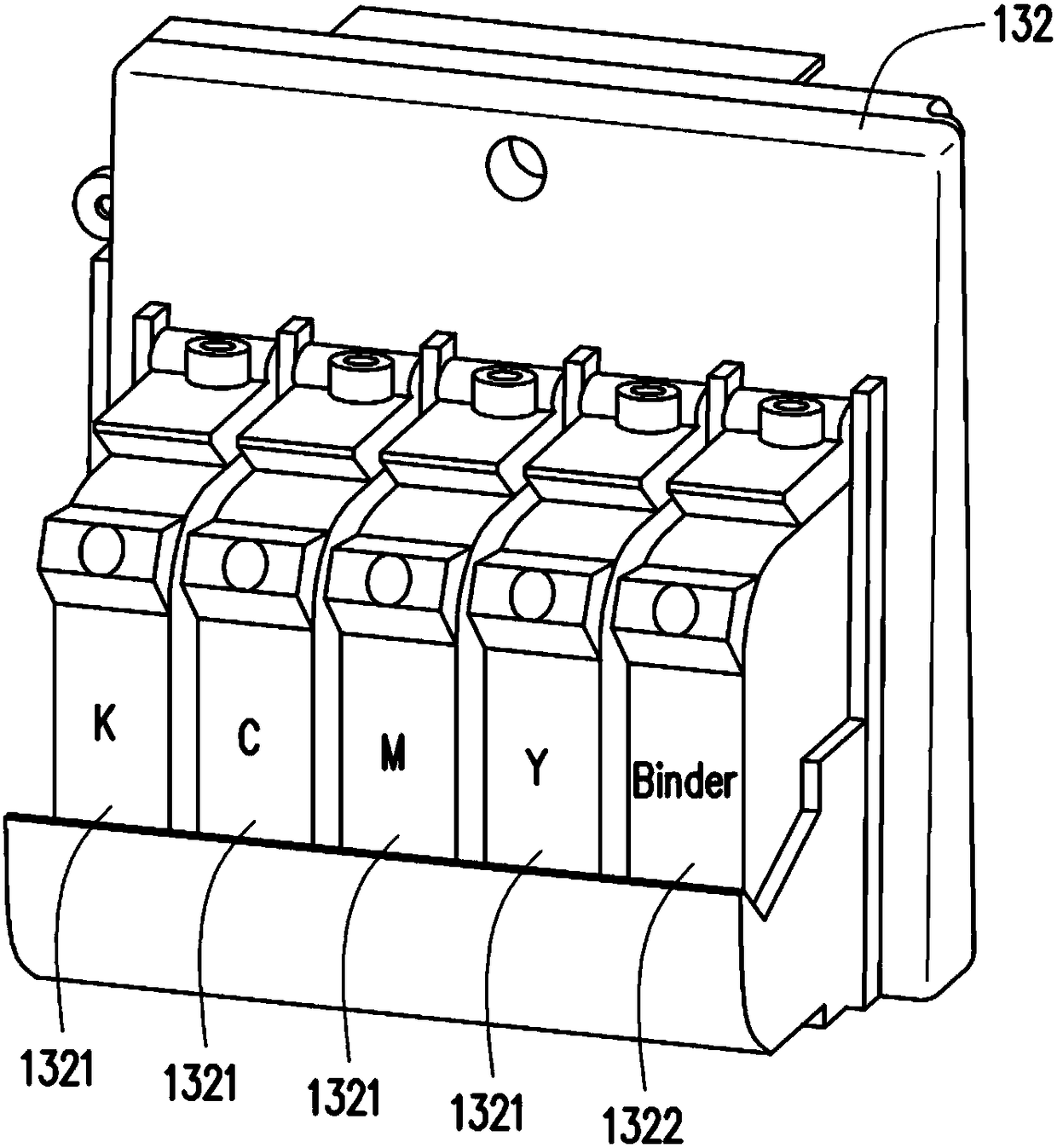

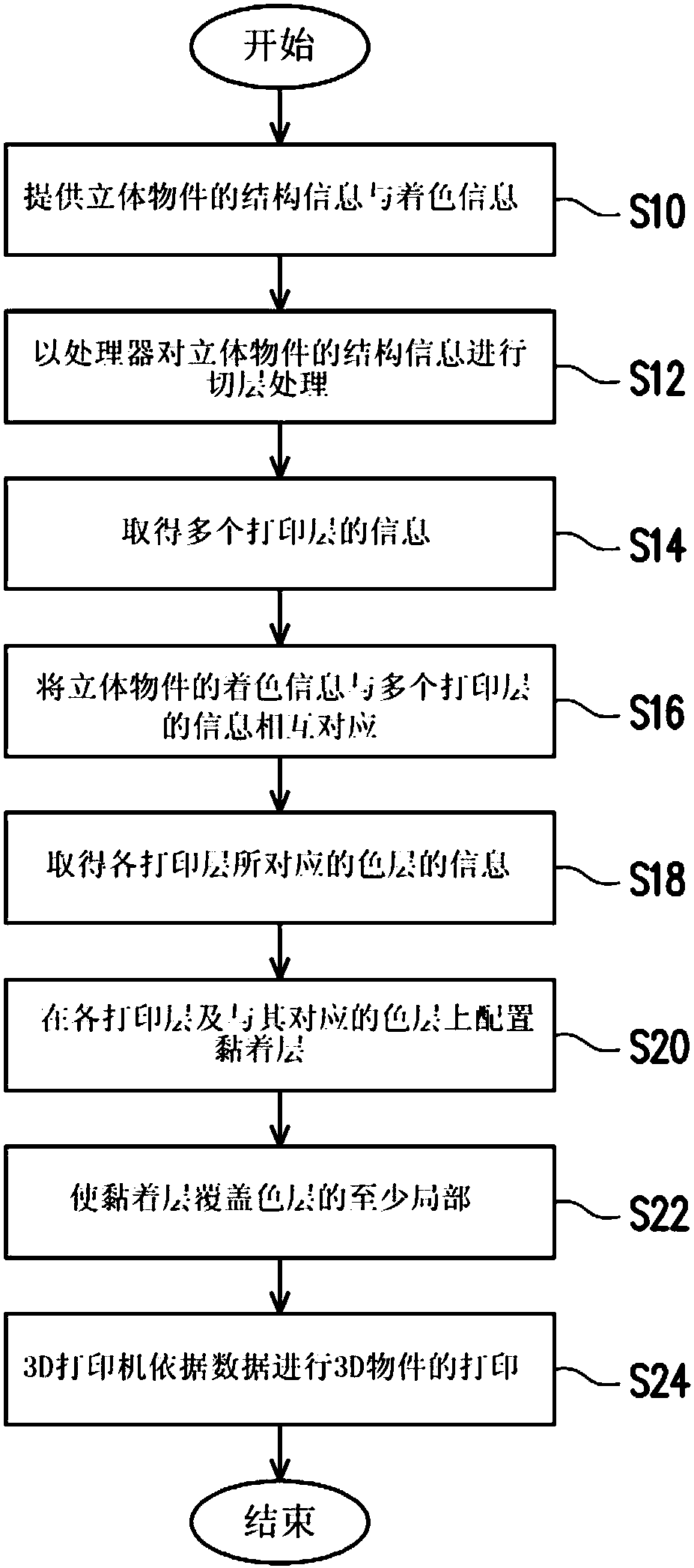

[0039] figure 1 It is a partial schematic diagram of a three-dimensional printing apparatus according to an embodiment of the present invention. figure 2 display figure 1 A partial schematic diagram of the printing assembly. Please also refer to Figure 1 to Figure 2 In this embodiment, the 3D printing apparatus 100 includes a frame 110, a platform 120, and a printing assembly 130. In addition, rectangular coordinates are provided to facilitate description. Here, the 3D printing device 100 is, for example, a fused deposition modeling (FDM) device, which can print the printing layer layer by layer on the platform 120 through the printing nozzle 131 of the printing assembly 130, and stack 3D objects layer by layer. . Furthermore, the printing assembly 130 further includes a coloring nozzle 132, which is, for example, an inkjet head, for coloring the surface of the printing layer or the three-dimensional object. In this embodiment, the colored nozzle 132 includes a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com