Heat radiator

A technology for heat sinks and heat sinks, applied in indirect heat exchangers, lighting and heating equipment, electrical components, etc., can solve problems such as hindering heat transfer, limited thermal conductivity of heat-absorbing bottom plates, and reducing heat dissipation performance of heat sinks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

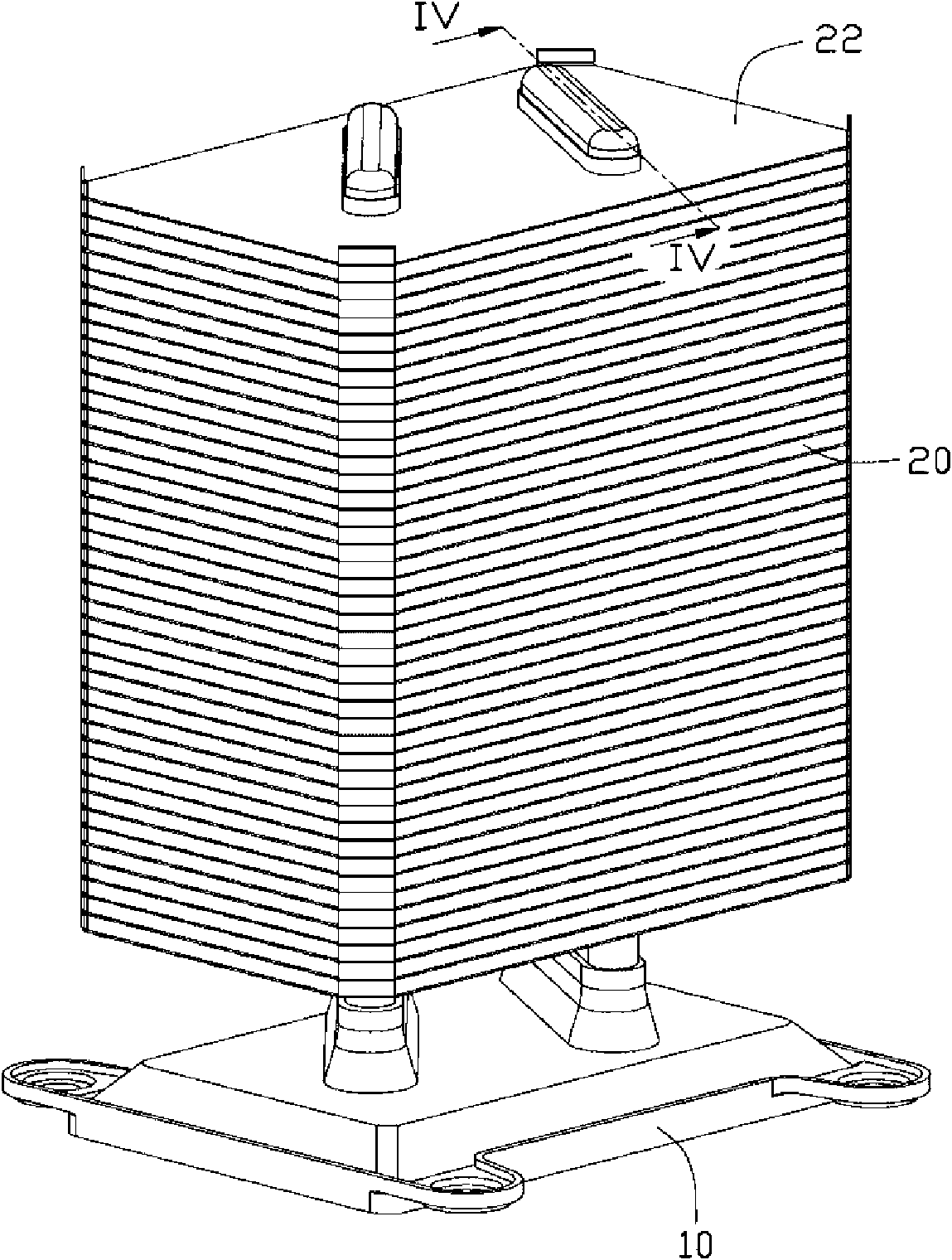

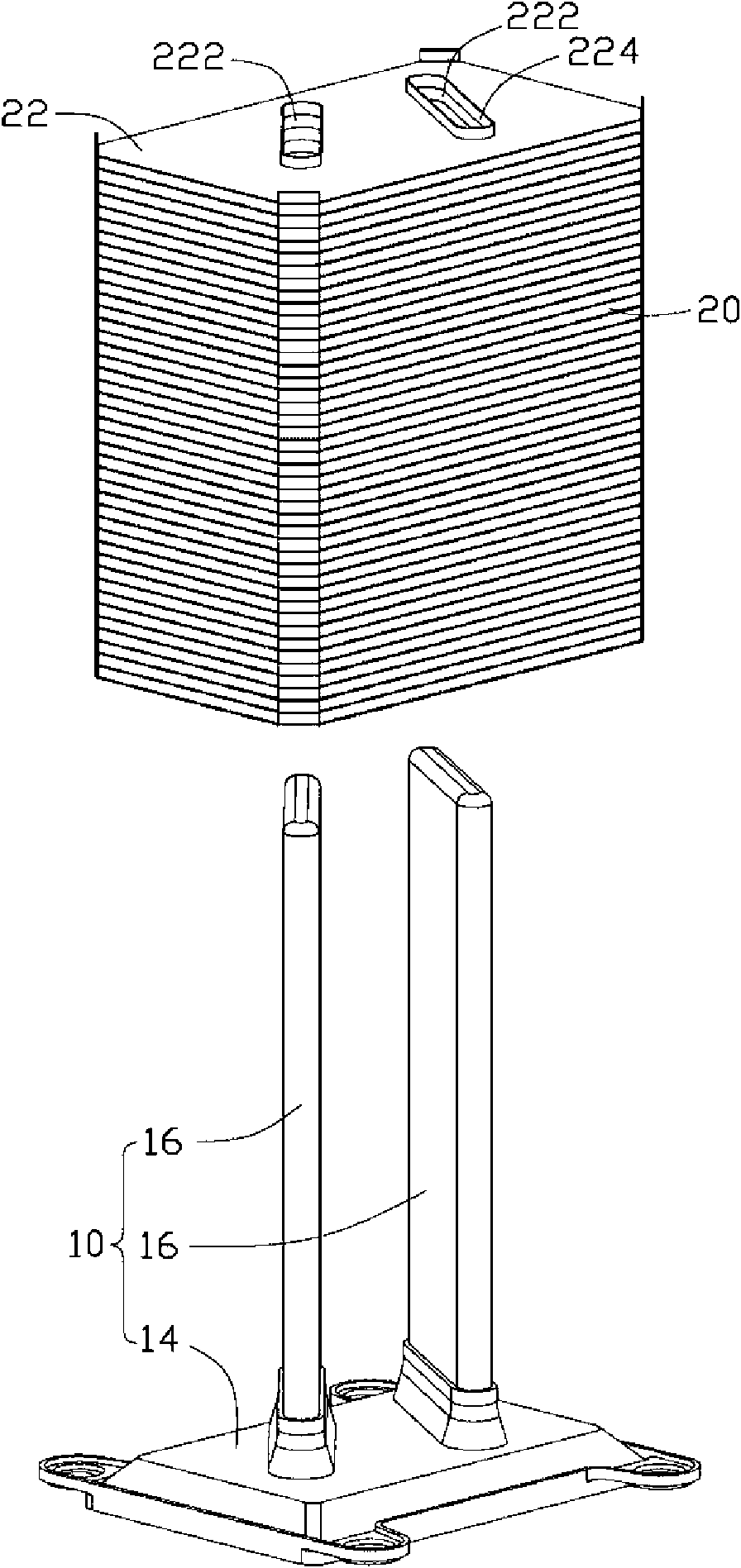

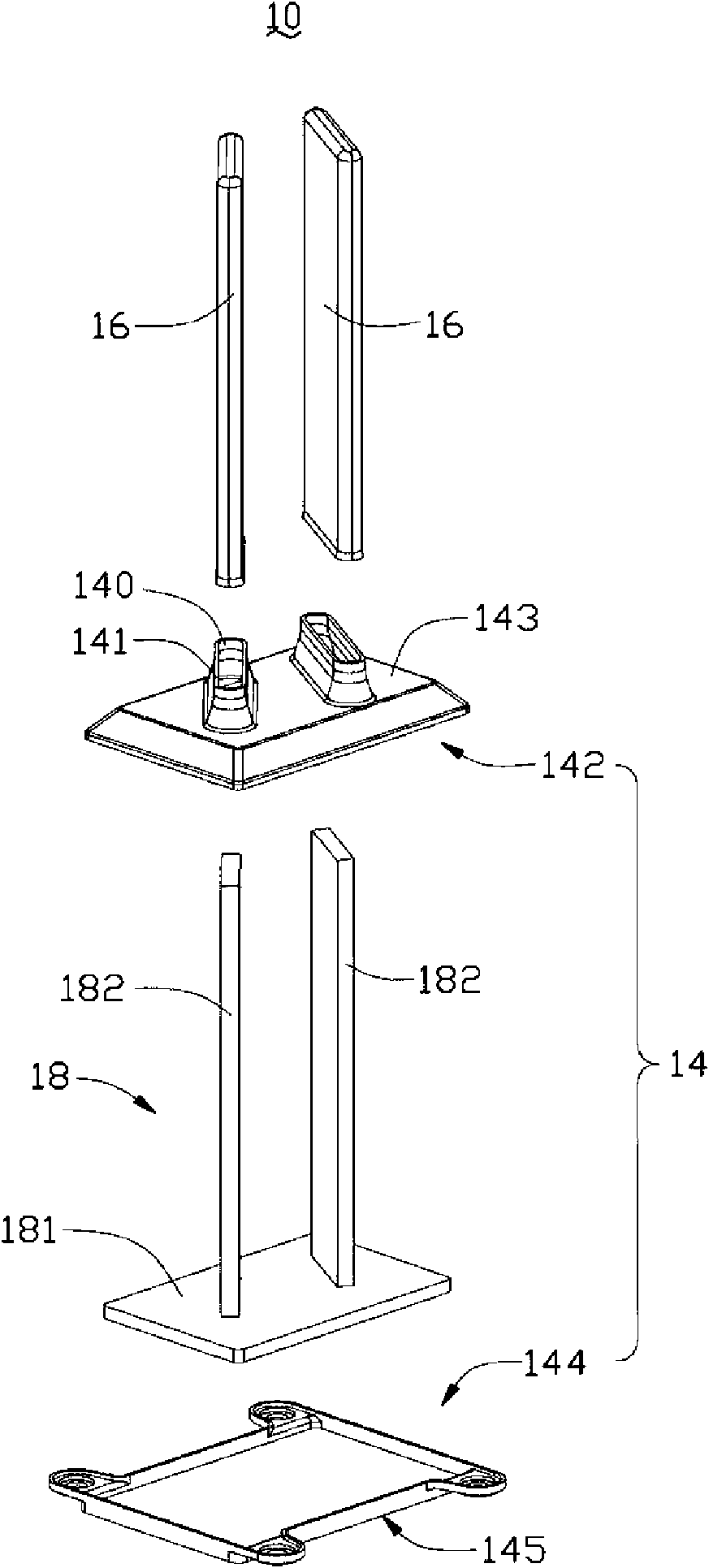

[0011] see figure 1 and figure 2 , the heat dissipation module includes a heat transfer body 10 and a heat dissipation body 20 .

[0012] The radiator 20 is formed by stacking a plurality of parallel radiator fins 22 from top to bottom, and the radiator fins 22 are spaced apart from each other to form gaps between adjacent radiator fins 22 . Each heat dissipation fin 22 is roughly flat, with two adjacent strip-shaped holes 222 disposed in its middle, and the two holes 222 are roughly opposite to each other in a "eight" shape. The strip-shaped holes 222 on all the heat dissipation fins 22 are aligned with each other from top to bottom, so as to jointly form two through holes that penetrate the entire heat dissipation body 20 along the stacking direction of the heat dissipation fins 22 . A ring 224 protrudes upward from the periphery of each strip hole 222 .

[0013] Please also see image 3 and Figure 4 , the heat transfer body 10 is a hollow structure, and a capillary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com