Transparent and toughened polymethyl methacrylate (PMMA) material and preparation method thereof

A toughening and transparent technology, applied in the field of transparent and toughened PMMA materials and their preparation, can solve the problems of few PMMA modified materials, inability to have both transparency and high toughness, and achieve good fluidity, high toughness, high transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

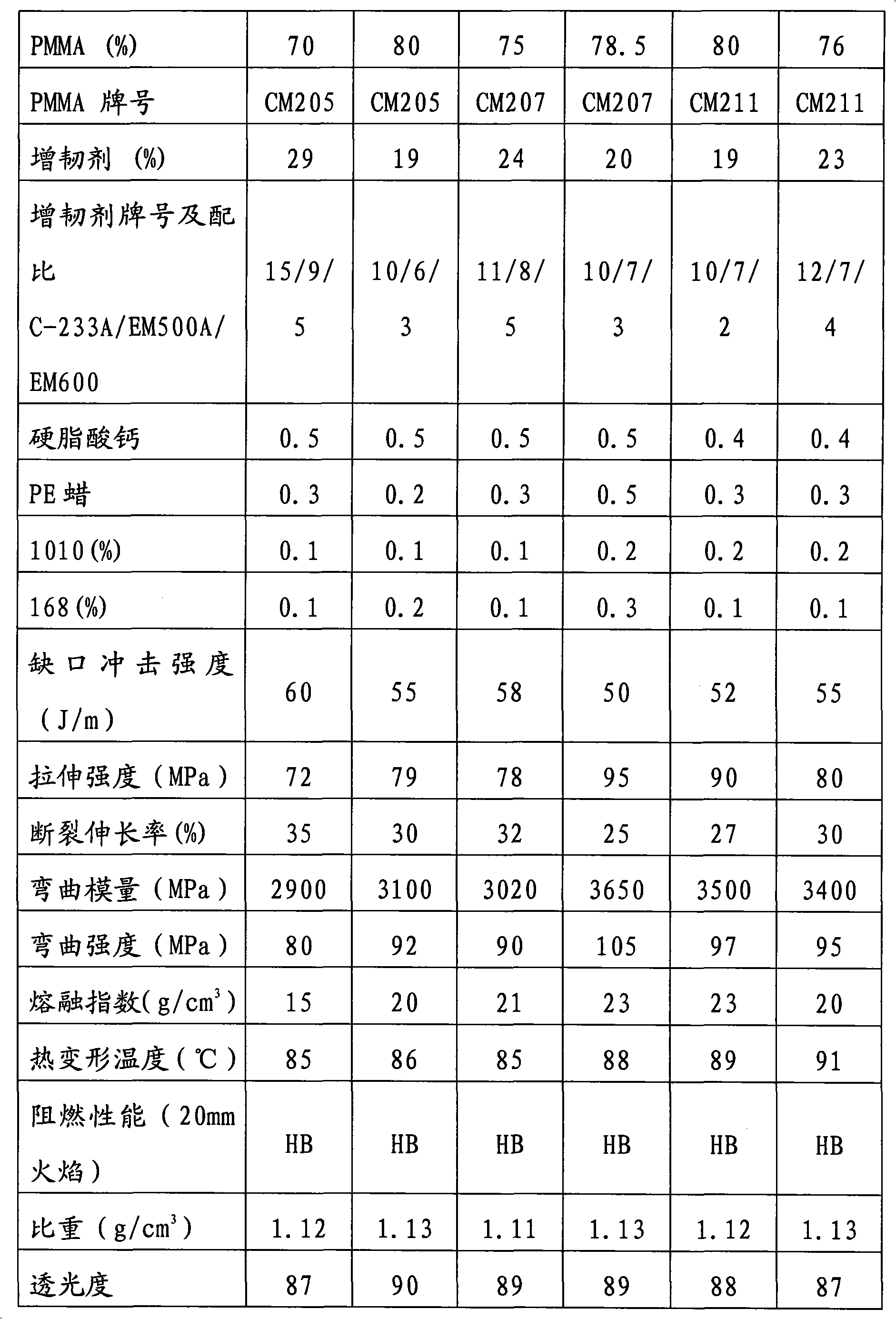

Embodiment 1

[0030] PMMA (brand is CM205) weight ratio is 70% (both percentages by weight), toughening agent 29% (wherein C-233A / EM500A / EM600=15 / 9 / 5), lubricant 0.8%, antioxidant 0.2 % mixing, the mixed materials are added into the hopper of the twin-screw extruder, melted and blended, extruded and granulated into alloy materials. Among them, the temperature settings of each zone of the screw are: the temperature of the first zone of the twin-screw extruder is 190-200°C, the temperature of the second zone is 210-220°C, the temperature of the third zone is 220-225°C, the temperature of the fourth zone is 210-220°C, and the head is 200- 205°C, residence time 1-2min, pressure 10-20MPa.

Embodiment 2

[0032] PMMA (brand is CM205) weight ratio is 80% (both percentages by weight), toughening agent 19% (wherein C-233A / EM500A / EM600=10 / 6 / 3), lubricant 0.7%, antioxidant 0.3 % Mixing Add the mixed materials into the hopper of the twin-screw extruder, melt and blend, extrude and granulate into alloy materials. Among them, the temperature settings of each zone of the screw are: the temperature of the first zone is 190-200°C, the temperature of the second zone is 210-220°C, the temperature of the third zone is 220-225°C, the temperature of the fourth zone is 210-220°C, the head is 200-205°C, the residence time 1~2min, the pressure is 10-20MPa.

Embodiment 3

[0034] PMMA (brand is CM207) weight ratio is 75% (both percentage by weight), toughening agent 24% (wherein C-233A / EM500A / EM600=11 / 8 / 5), lubricant 0.8%, antioxidant 0.2 % mixing, the mixed materials are added into the hopper of the twin-screw extruder, melted and blended, extruded and granulated into alloy materials. Among them, the temperature settings of each zone of the screw are: the temperature of the first zone is 190-200°C, the temperature of the second zone is 210-220°C, the temperature of the third zone is 220-225°C, the temperature of the fourth zone is 210-220°C, the head is 200-205°C, the residence time 1~2min, the pressure is 10-20MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com