Code-spraying printing ink

A technology for printing ink and coding, applied in inks, household appliances, applications, etc., can solve the problems of slow evaporation, difficulty in taking into account color recognition, excitation, luminescence, and difficulty in drying, and achieve accurate and clear reading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

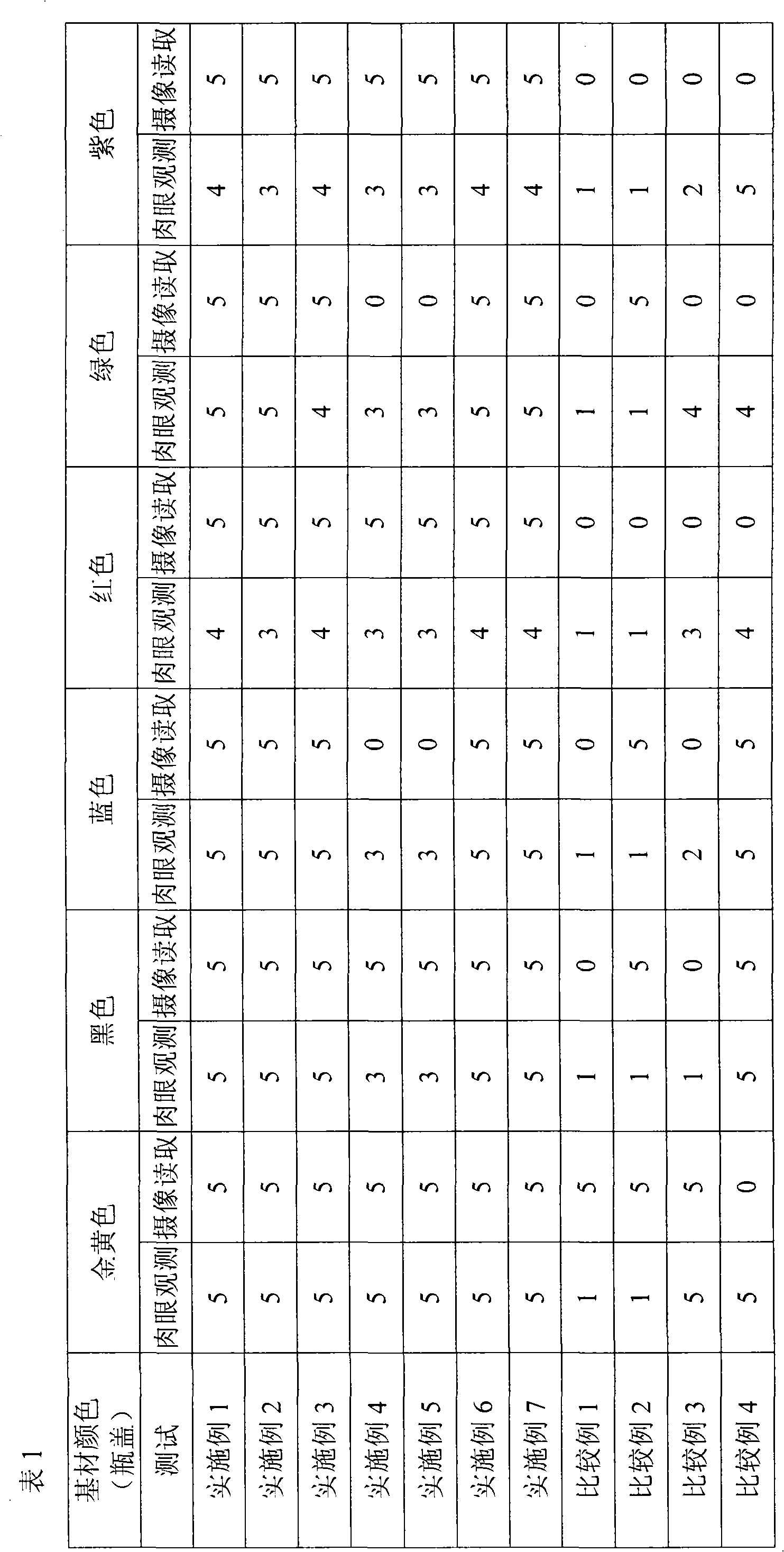

Examples

Embodiment 1

[0021] The composition of inkjet printing ink, with the total weight of inkjet printing ink as 100%:

[0022] Butanone 75

[0023] 2013 Acrylic 5

[0024] fluorescent orange dye 18

[0025] ES-81 antistatic agent 2

Embodiment 2

[0027] The composition of inkjet printing ink, with the total weight of inkjet printing ink as 100%:

[0028] Butanone 78

[0029] 2013 Acrylic 5

[0030] fluorescent orange dye 15

[0031]ES-81 antistatic agent 2

Embodiment 3

[0033] The composition of inkjet printing ink, with the total weight of inkjet printing ink as 100%:

[0034] Acetone 73.5

[0035] Cyclohexanone 1.5

[0036] BN18PVB resin 5

[0037] Fluorescent yellow dye 18

[0038] ES-81 antistatic agent 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com