Tray (well) diameter detector

A detector and diameter measuring technology, which is applied in the directions of measurement, wellbore/well parts, earthwork drilling and production, etc., can solve the problem of good economic and social benefits, which is difficult to promote and apply, and cannot effectively detect and supervise the supporting pile technology. Problems such as the construction quality of coiled piles, achieving good economic and social benefits, easy to popularize and use, and ensuring the quality of the pile body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

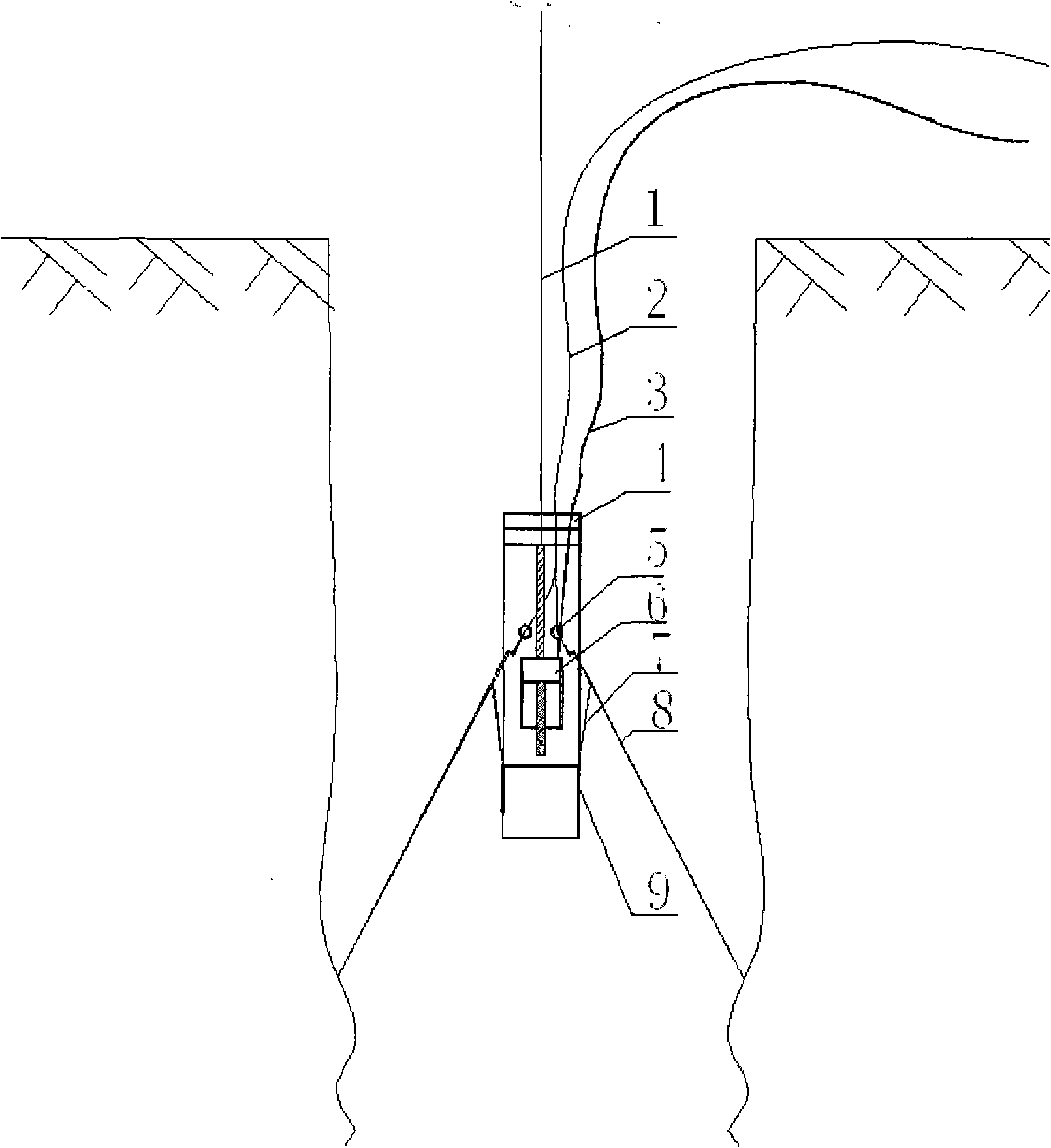

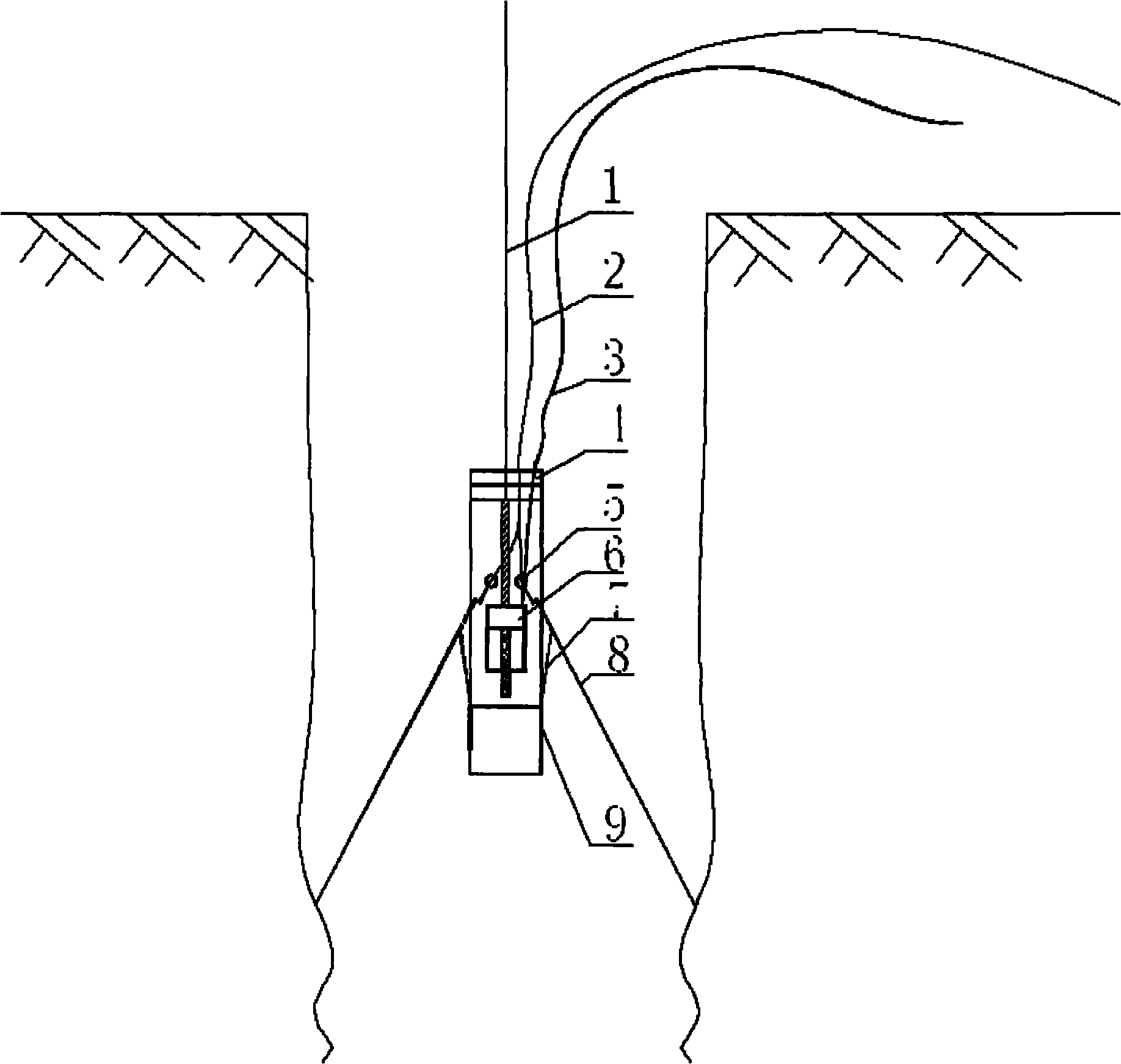

[0009] like figure 1 As shown: the caliper arm 8 is hinged with the pull rod 7, the caliper arm tension spring 9 is hinged with the pull rod 7, the inclination sensor 5 is fixed on the caliper arm 8, and the retracting arm hydraulic cylinder 6 is fixed on the outer seat 4 of the instrument for oil supply. The pipe 3 is connected with the arm retracting hydraulic cylinder 6, the information output line 2 is connected with the inclination sensor 5, and the instrument sling 1 is connected with the instrument outer seat 4.

[0010] The extrusion plate (well) diameter detector works like this: when the hole is drilled, the instrument sling 1 hangs the equipment down, and supplies oil to the retracting arm hydraulic cylinder 6 through the oil supply pipe 3, so that the tension spring 9 of the measuring arm shrinks, At the same time, the pull rod 7 is driven, and the caliper arm 8 is in the recovery state; during measurement, the instrument sling 1 hangs the equipment up, and at this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com