Three-degree-of-freedom precision-positioning workbench

A precision positioning and worktable technology, applied in the direction of machine/support, supporting machine, mechanical equipment, etc., can solve the problems of increasing control difficulty, input and output coupling, and affecting work accuracy, so as to increase work flexibility and improve precision , to avoid the effect of accumulating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention should not be limited thereby.

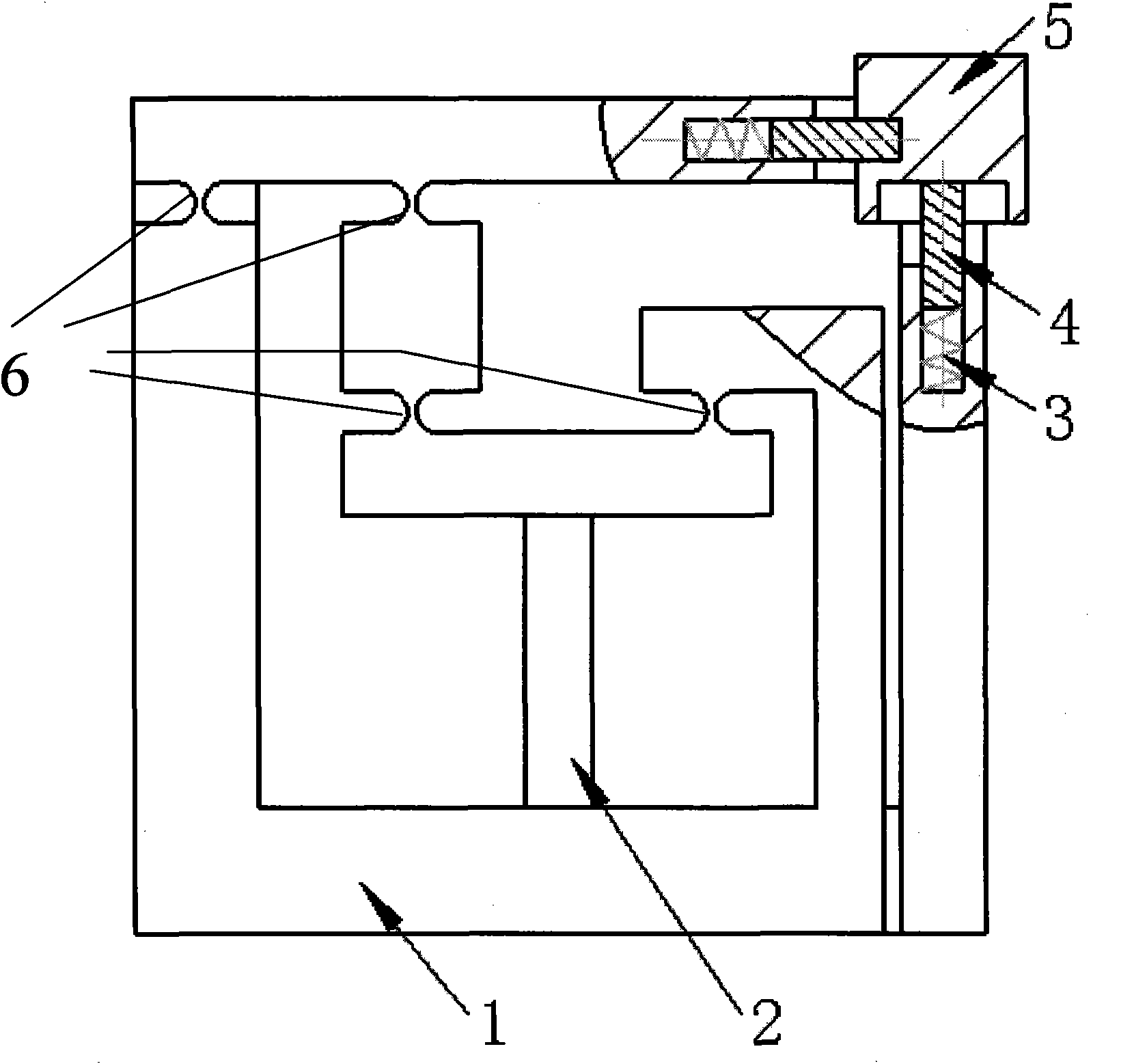

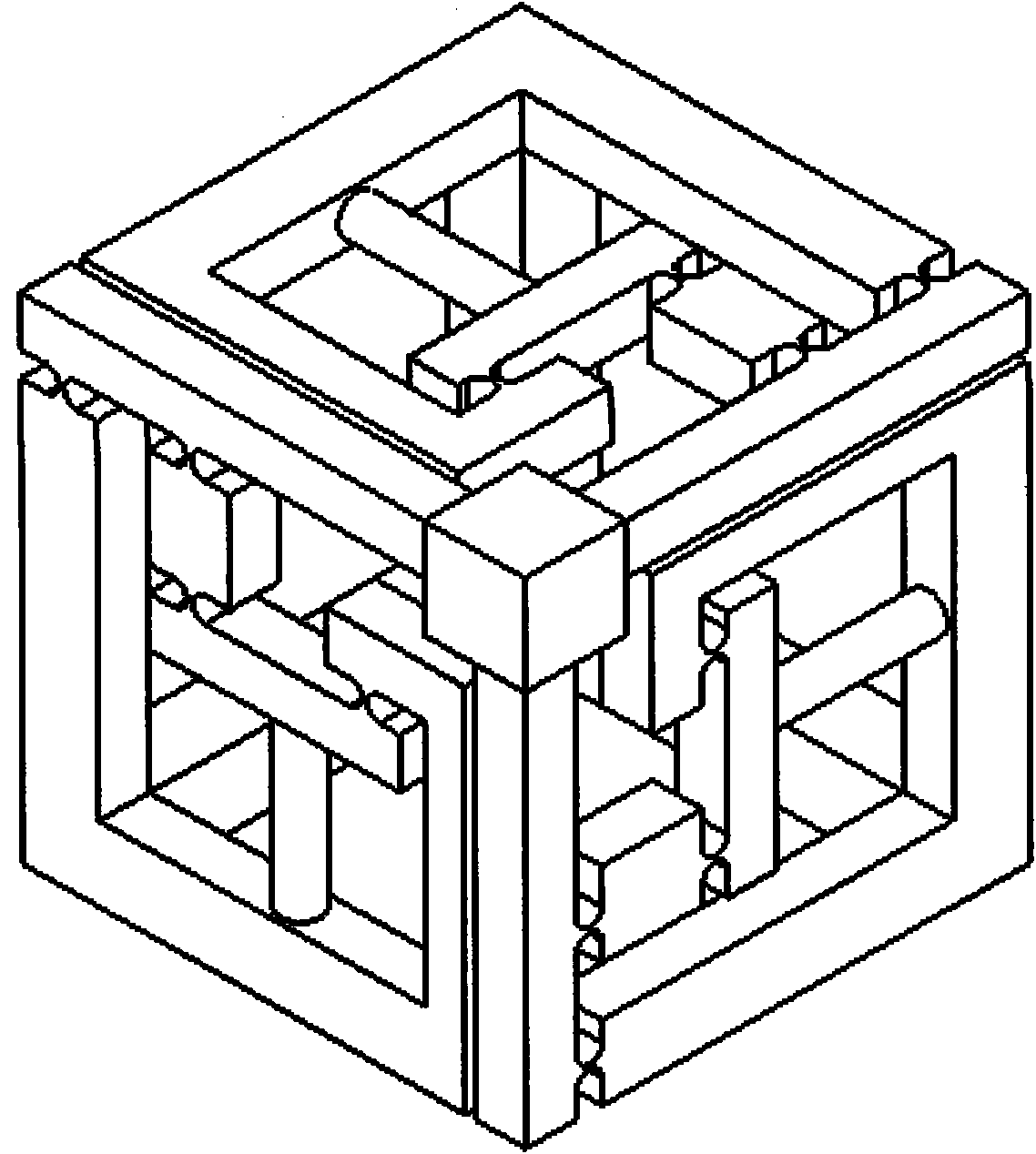

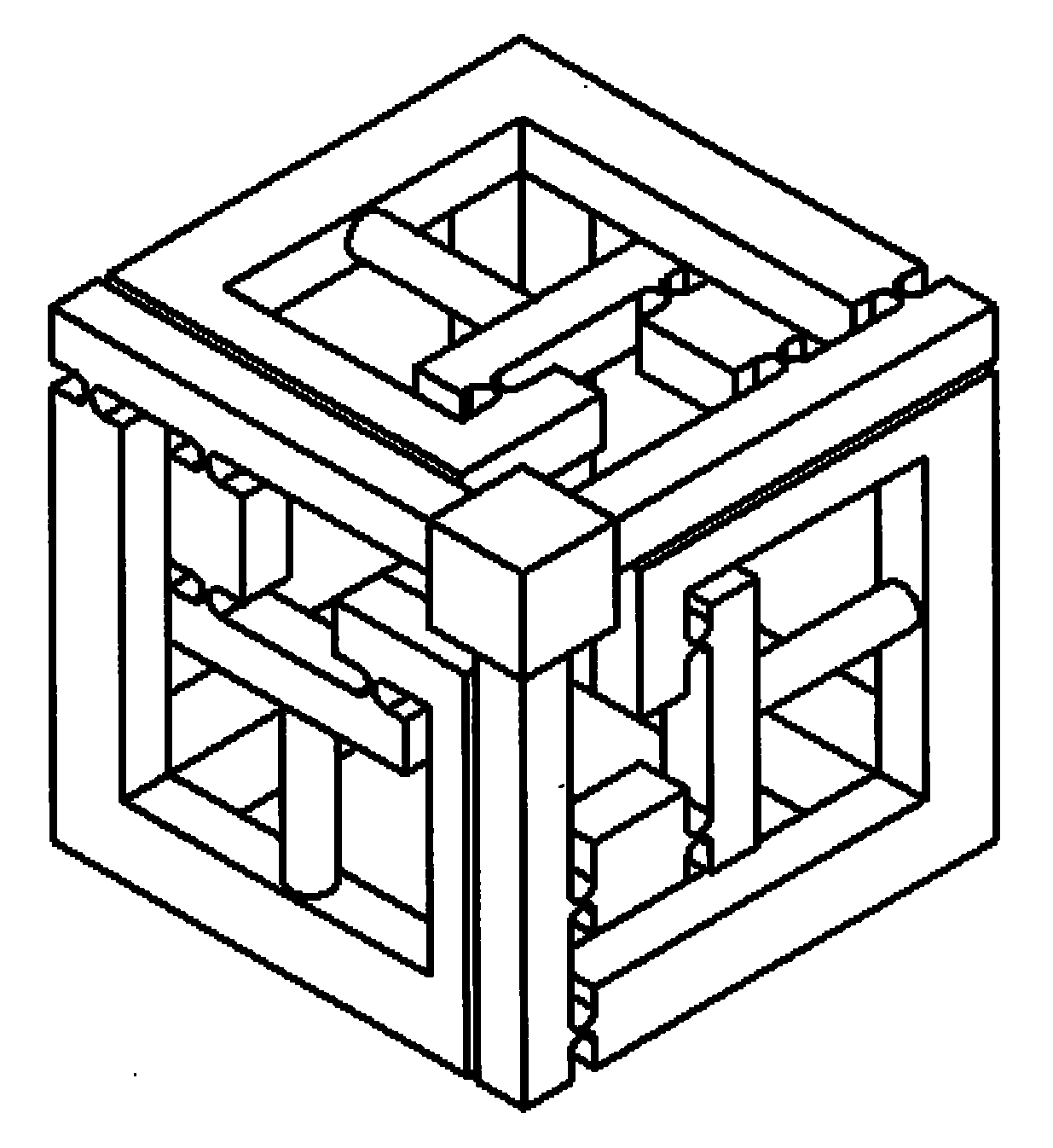

[0015] as attached figure 1 , figure 2 As shown, the three-degree-of-freedom precision positioning workbench of the present invention includes a work platform 5 and an enlarged base 1, and the work platform 5 and the enlarged base 1 are connected by three cylindrical rods 4. The enlarged base 1 is composed of three groups of secondary amplifying mechanisms vertically intersecting each other.

[0016] The cylindrical rod 4 is pushed by the spring 3 and is preloaded by the spring 3, and the cylindrical rod 4 can move in the enlargement base 1 with the expansion and contraction of the spring 3.

[0017] The working platform 5 has internal grooves perpendicular to each other on three adjacent surfaces, which are used to control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com