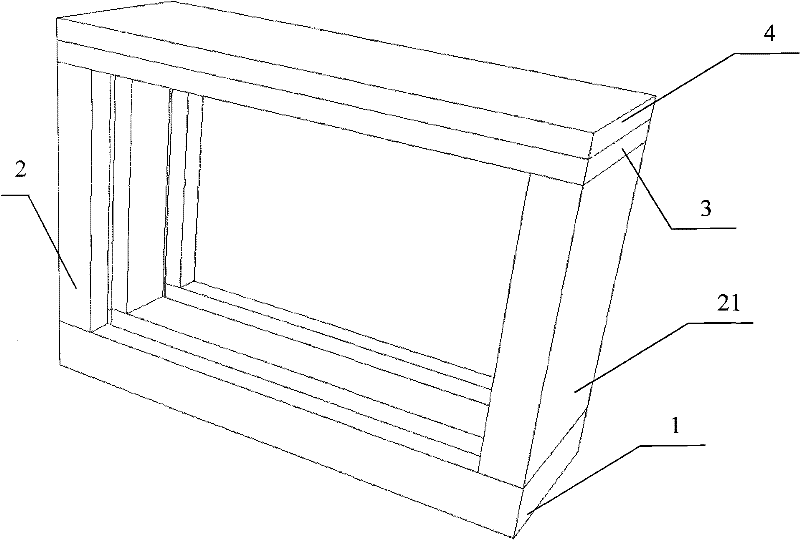

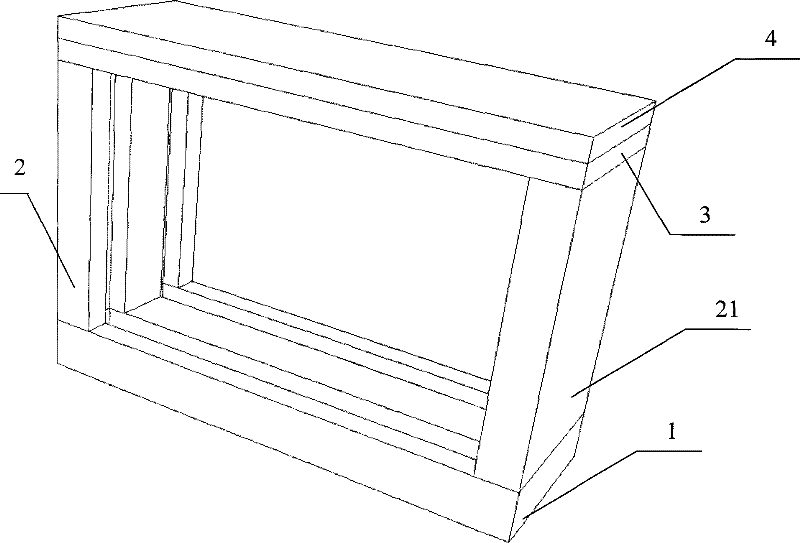

Built-in carbon box type sealed device for horizontal kiln and sealing method

A horizontal furnace, carbon-based technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of high cost, time-consuming, troublesome, affecting the atmosphere in the kiln and product quality, etc., to improve product quality, maintain The effect of stabilizing and reducing the heat storage of the kiln body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] In the test of the pre-trial production of this embodiment 1, the boride ceramics were fired, and the built-in carbon box-type airtight device for the horizontal furnace of the present invention was not provided in the horizontal furnace, and the gas produced in the firing process In direct contact with refractory materials, the firing cycle is 22.3 hours, the daily output is 2.8 tons, the qualified rate is 90.02%, the first-grade product rate is 74.78%, the reject rate is 4.16%, the power consumption is 8526kWh / ton, and the heating element replacement frequency 0.41 sticks / day.

Embodiment 2

[0067]In the test of the pre-trial production of Example 2, boride ceramics were fired, and a steel shell was used to seal the outside of the horizontal kiln. The firing cycle was 21.4 hours, the daily output was 3.2 tons, and the pass rate was 91.35%. The product rate is 76.78%, the reject rate is 3.77%, the power consumption is 8124kWh / ton, and the heating element replacement frequency is 0.36 pieces / day.

Embodiment 3

[0069] In the test of the pre-trial production of Example 3, boride ceramics were fired, and a carbon furnace was built in a horizontal kiln without sealing. The firing cycle was 22.5 hours, the daily output was 3.4 tons, and the qualified rate was 91.01 %, the first-class product rate is 75.62%, the scrap rate is 3.58%, the power consumption is 8258kWh / ton, and the heating element replacement frequency is 0.33 pieces / day.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com