Pelletizing drying technology and equipment for smelting alusil alloy

An aluminum-silicon alloy, drying process technology, applied in the direction of drying solid materials, progressive dryers, lighting and heating equipment, etc., can solve the problems of ineffective collection of slag, complex mechanical structure, and many materials for manufacturing, and achieve drying process. Reasonable temperature curve, good safety performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

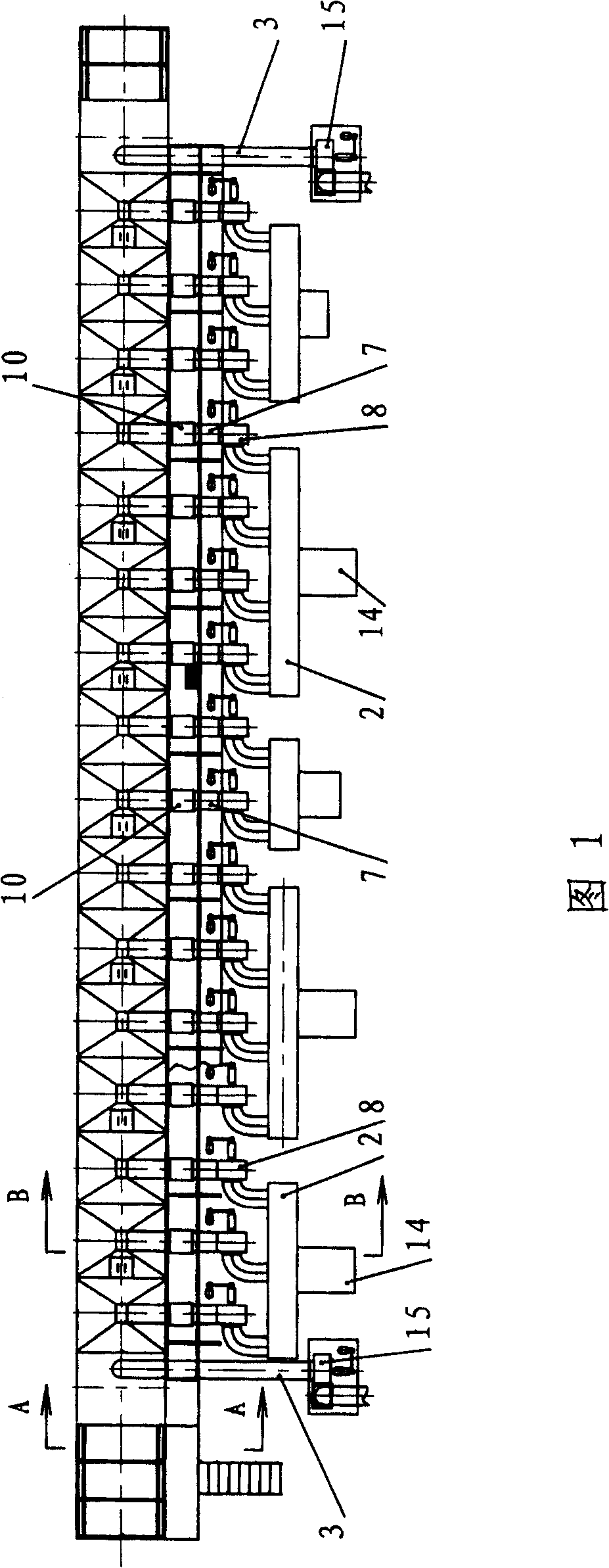

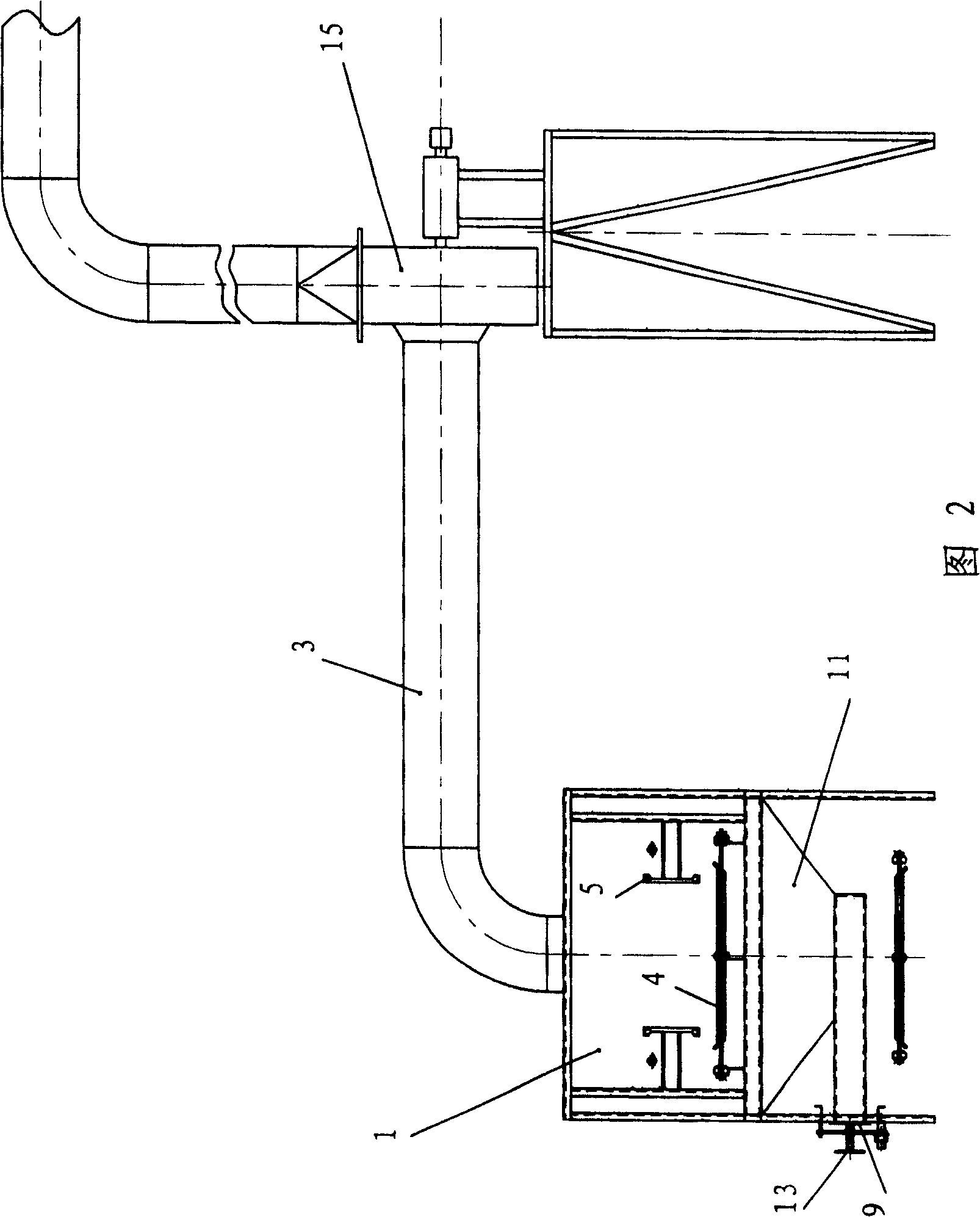

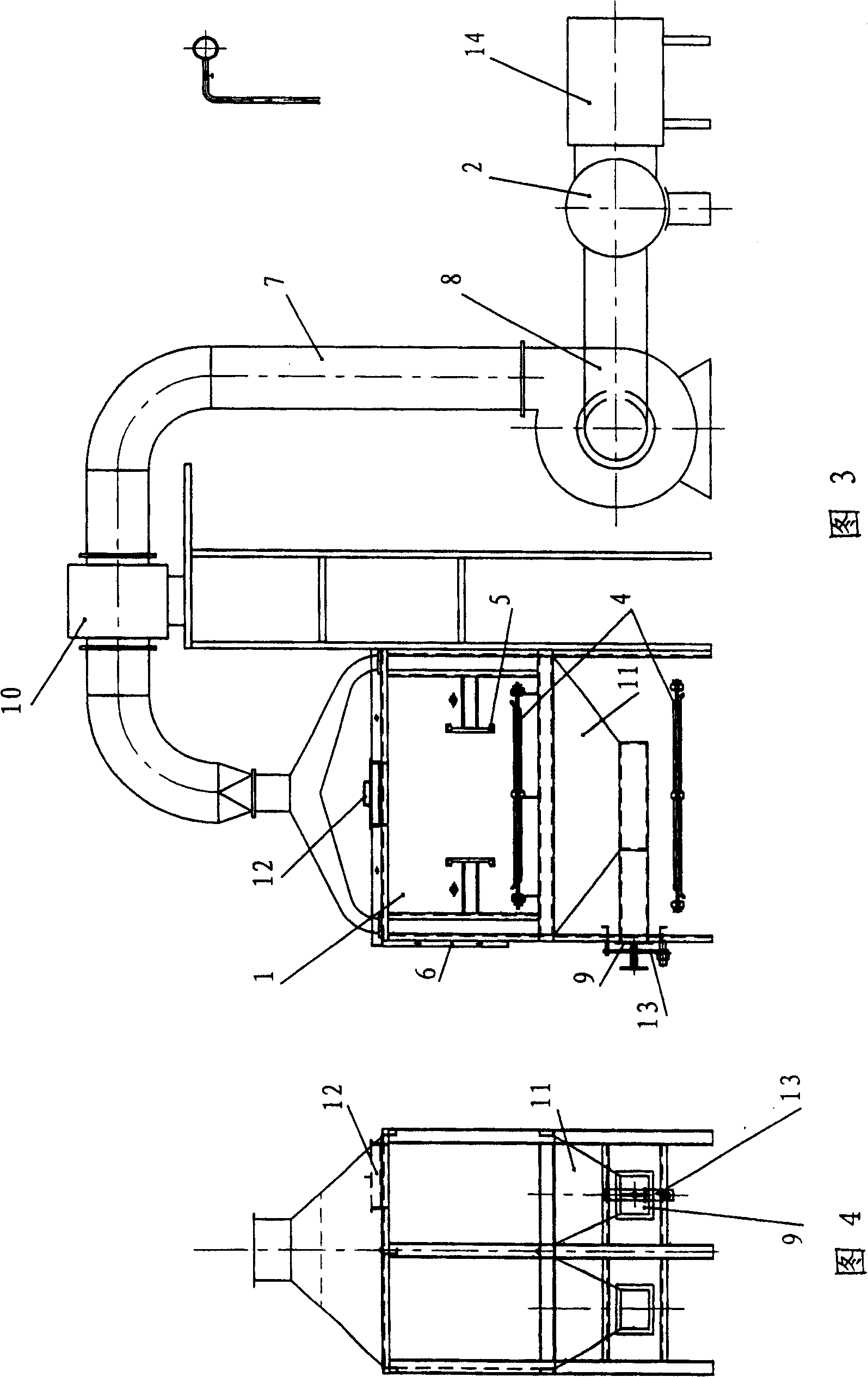

[0026] As shown in Figure 1, the pellet drying process for smelting aluminum-silicon alloy of the present invention comprises the following steps:

[0027] (1) Lay the pellets to be dried on the mesh conveyor belt 4 of the belt dryer. The moisture content of the pellets is 8%-35%, and the weight of the pellets to be dried is 70-90g / piece;

[0028] (2) Pass the hot air flow passing through the laying pellet layer to multiple drying temperature sections in the belt dryer, wherein the inlet drying temperature section with a length of 2m or 1m or 3m or 4m is introduced from the bottom And the temperature of the hot air flow passing through the pellet layer is 82°C or 87°C or 92°C or 97°C or 102°C or 112°C or 117°C or 127°C or 132°C or 137°C or 138°C. The temperature of the hot air flowing through the pellet layer from bottom to top in the second drying temperature section adjacent to the drying temperature section with a length of 14m or 12m or 15m or 16m is 202°C or 207°C or 212...

Embodiment 2

[0032] As shown in Figure 1, the pellet drying process for smelting aluminum-silicon alloy of the present invention comprises the following steps:

[0033] (1) Lay the pellets to be dried on the mesh conveyor belt 4 of the belt dryer. The thickness of the paving should be less than 260mm, generally 150mm-250mm. The moisture content of the pellets is 10%-16%, and the weight of the pellets to be dried is 70-90g / piece;

[0034] (2) Pass the hot air flow passing through the laying pellet layer to multiple drying temperature sections in the belt dryer, wherein the inlet drying temperature section with a length of 2m or 1m or 3m or 4m is introduced from the bottom The temperature of the hot air flow passing through the pellet layer is 80°C or 85°C or 90°C or 95°C or 100°C or 110°C or 115°C or 125°C or 130°C or 135°C or 140°C. The temperature of the hot air flowing through the pellet layer from bottom to top in the second drying temperature section adjacent to the drying temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com