Automatic test device for simulating ocean tide environment

A test device and tidal technology, applied in the field of automated test devices, can solve the problems of resistance to chloride ion corrosion, accelerated concrete specimens, and inability to simulate ocean tidal environment, and achieve the effects of reliable production requirements, convenient maintenance, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

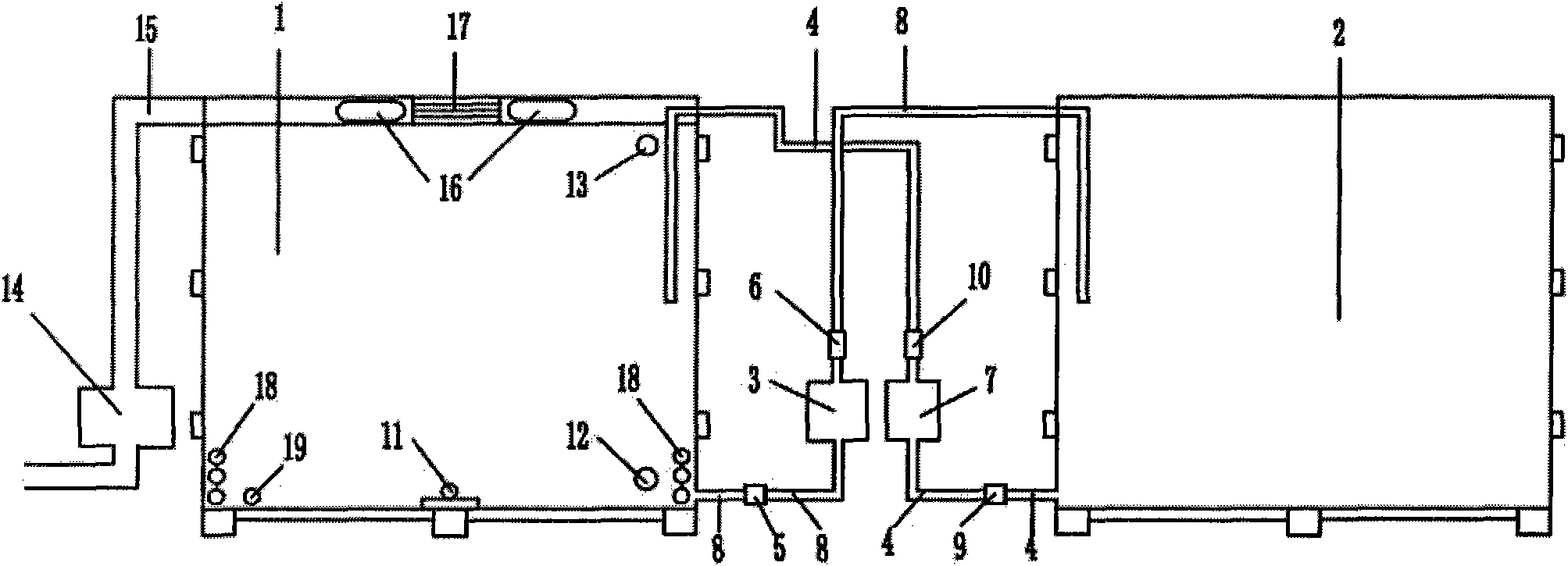

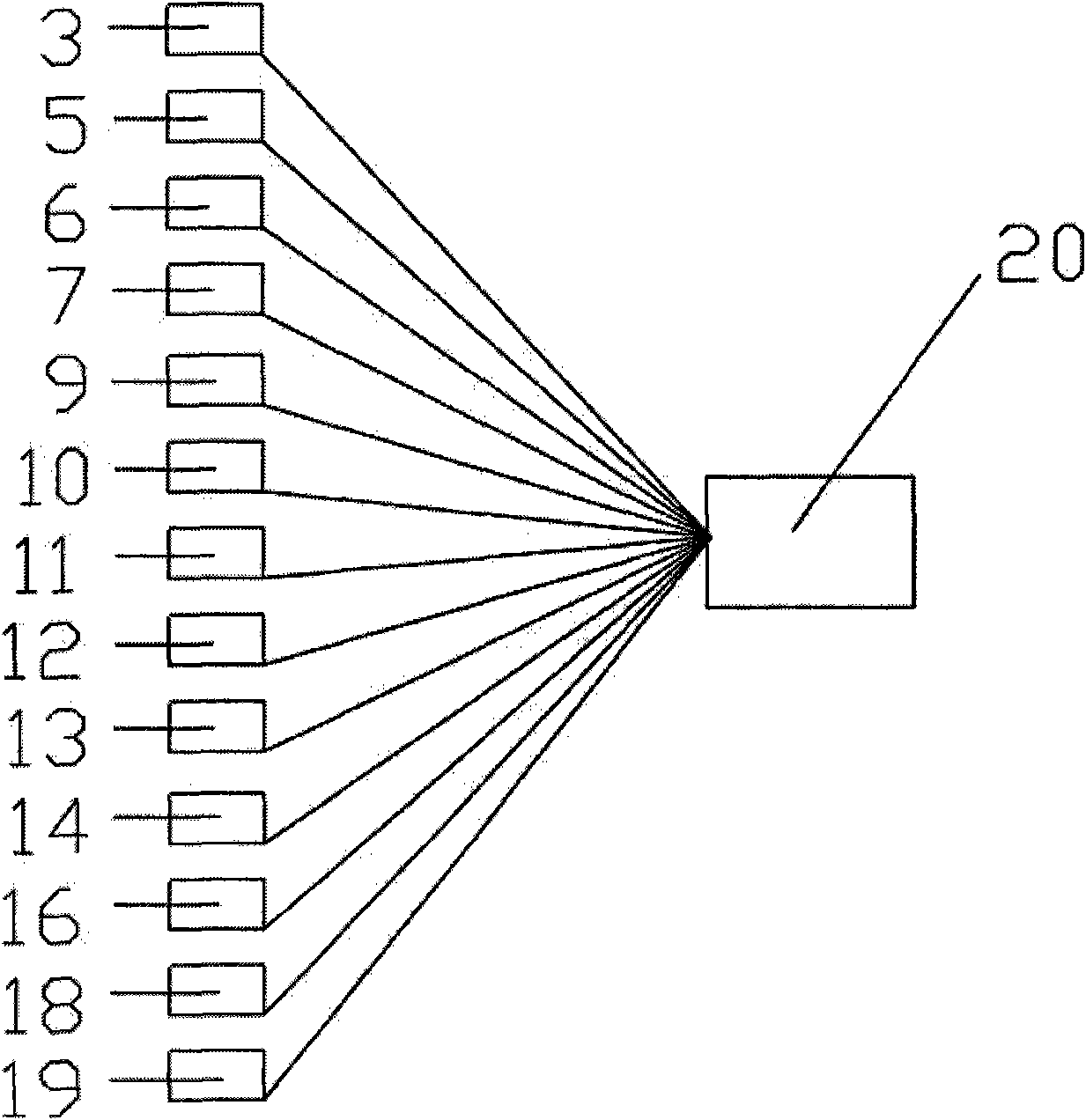

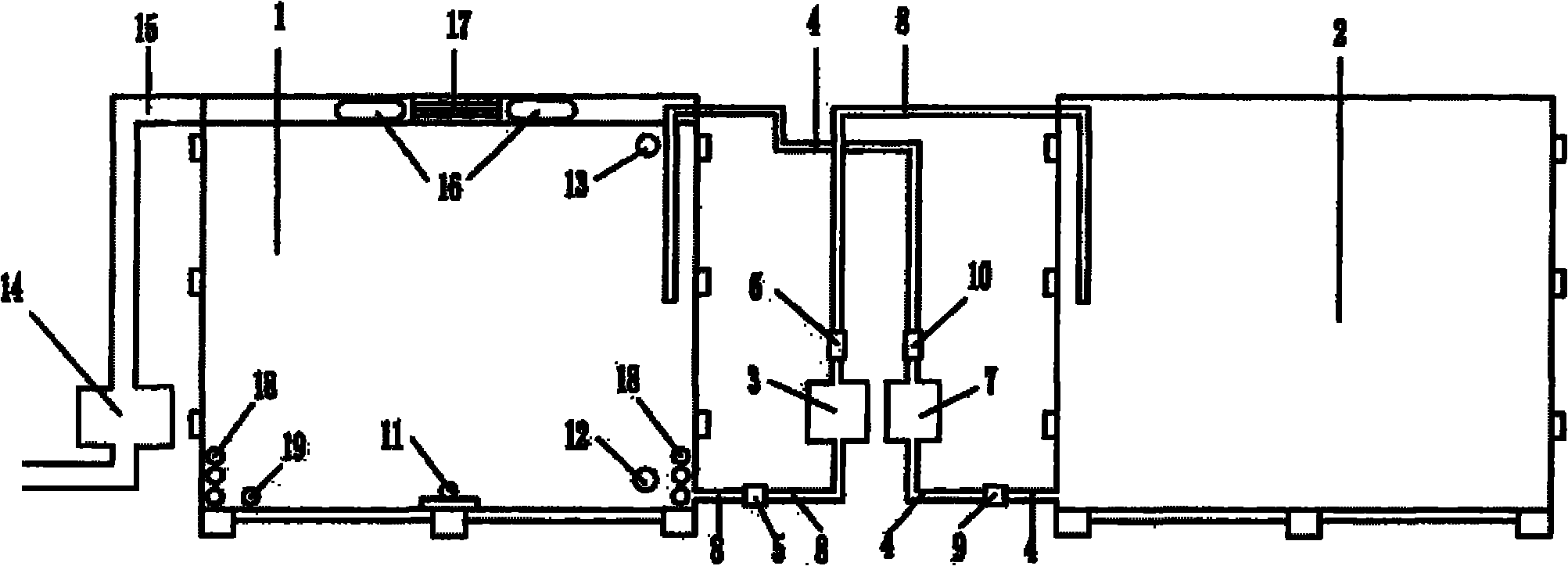

[0012] Such as figure 1 and figure 2 As shown, the automatic test device for simulating the ocean tidal environment of the present invention mainly includes a seawater circulation controller, a seawater temperature controller, a blowing device, a lighting device, a main corrosion working chamber, an auxiliary corrosion working chamber and a controller. The seawater circulation controller includes a water inlet device and a drainage device. The water inlet device includes a water inlet pipe 4, an inlet water pump 7, an inlet solenoid valve 9 and a first flow sensor 10; Valve 5, second flow sensor 6.

[0013] Connect one end of the water inlet pipe 4 with the water outlet at the bottom of the auxiliary corrosion working chamber 2, then install the water inlet solenoid valve 9, the water inlet pump 7 and the first flow sensor 10 on the water inlet pipe 4 in sequence, and finally the other end of the water inlet pipe 4 It communicates with the water inlet on the top of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com