Flow divider for nose

A shunt and machine head technology, which is applied in the direction of insulating conductors/cables, can solve the problems of inconvenient and stable production, difficulty in ensuring product quality, and damage to the equilibrium state, and achieve thickness and uniformity guarantee, function improvement, and stable production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

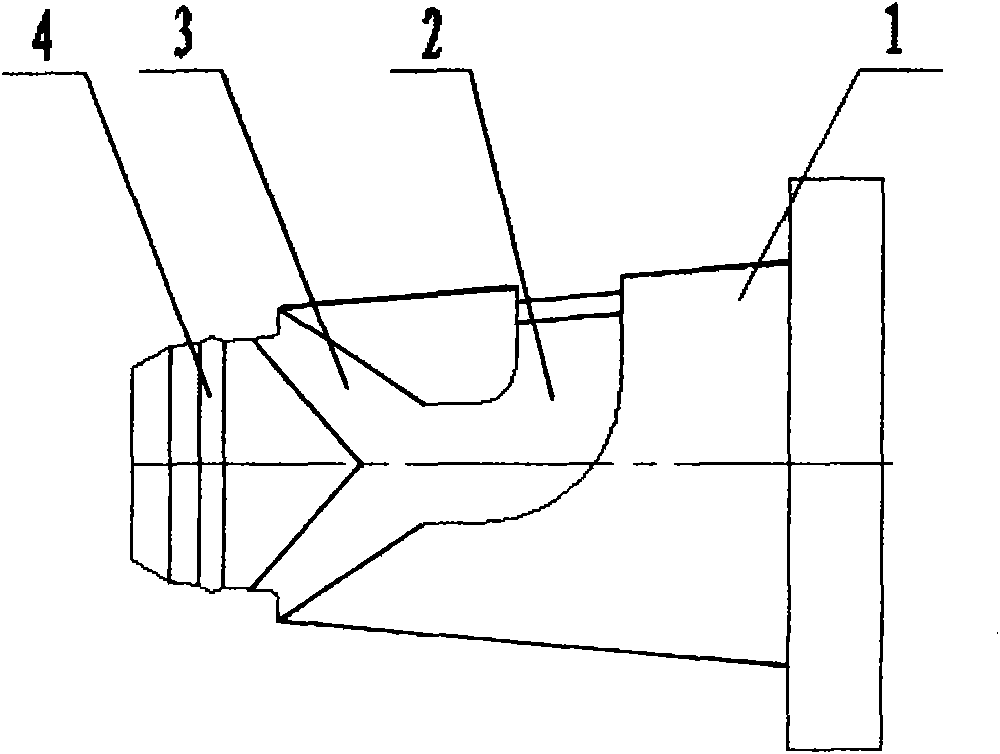

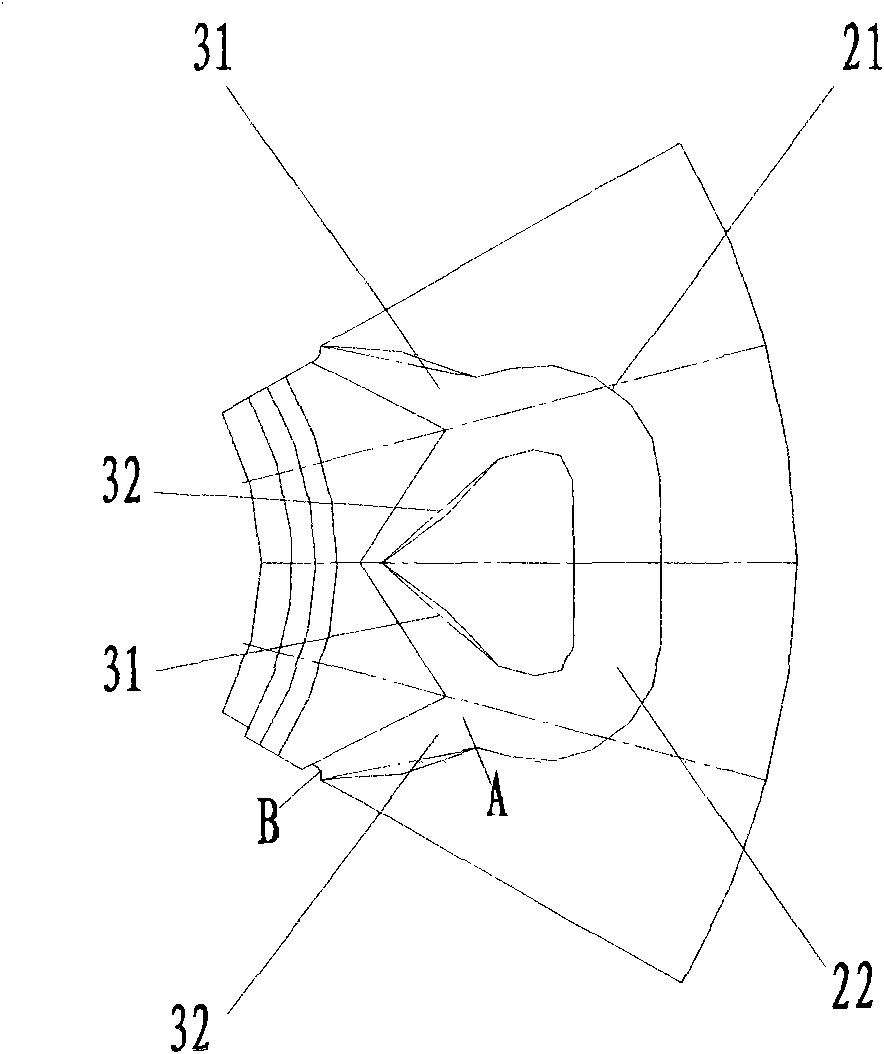

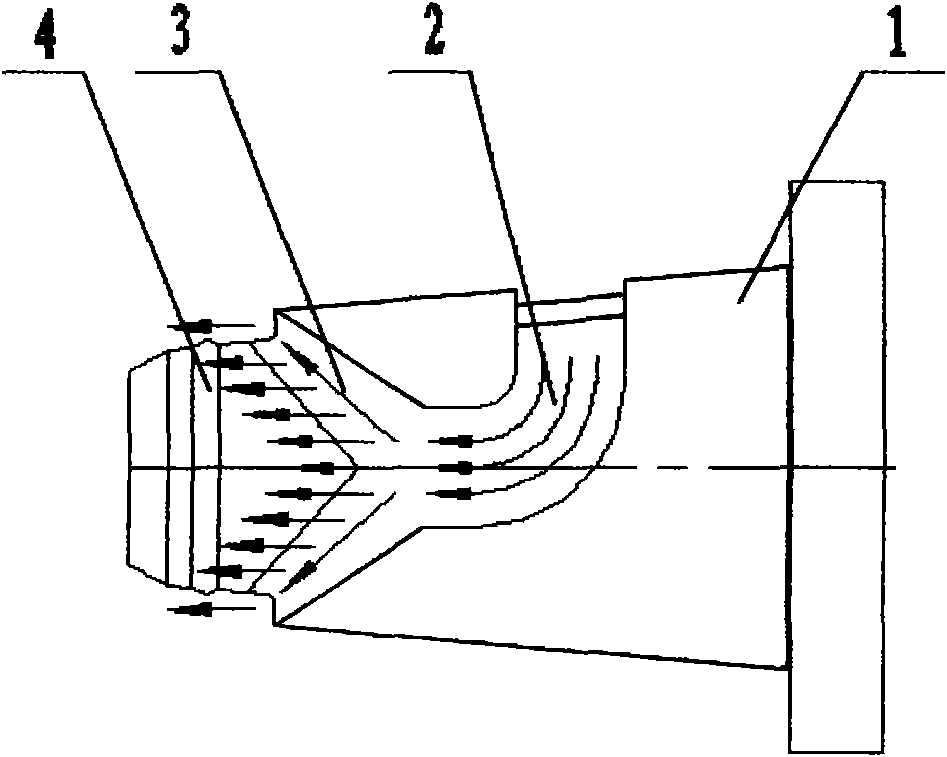

[0019] Such as Figure 1 to Figure 4 As shown, the head splitter of the present invention includes a splitter body 1, and a flow channel group is provided on the surface of the splitter body 1, and the flow channel group includes a first flow channel composed of two flow channels 21 and 22 in a bifurcated shape. In group 2, a second flow channel group 3 formed of two flow channels 31 and 32 in a bifurcated shape is respectively opened at the end of each flow channel 21, 22 of the first flow channel group 2.

[0020] Wherein, the diverter body 1 is cylindrical or conical, and the taper of the conical diverter body is 1°˜10°. The two runners 21 and 22 of the first runner group form an included angle of a certain degree; the two runners of the second runner group 3 also form an included angle of a certain degree. The groove is arc-shaped, and the outflow is evenly balanced. The connecting line between the end of the first group of flow channels and the end of the second group o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com