Method and equipment for disassembling waste ceramic resistors and recovering resources

A waste ceramics and resource recovery technology, applied in chemical instruments and methods, solid waste removal, solid separation, etc., can solve the problems of landfill soil pollution, waste of resources, pollution of the environment, etc., and achieve no waste gas generation and low working noise , good environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

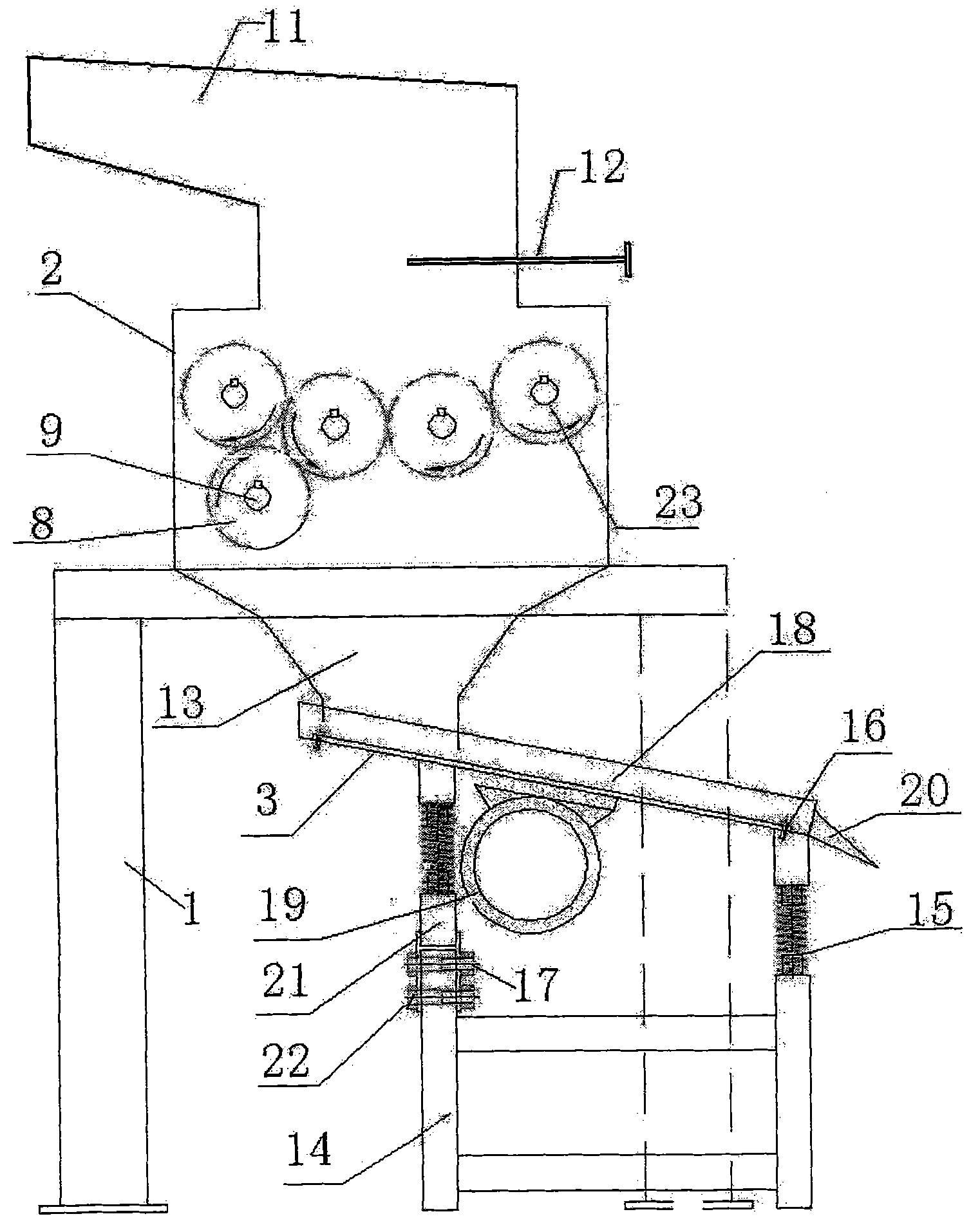

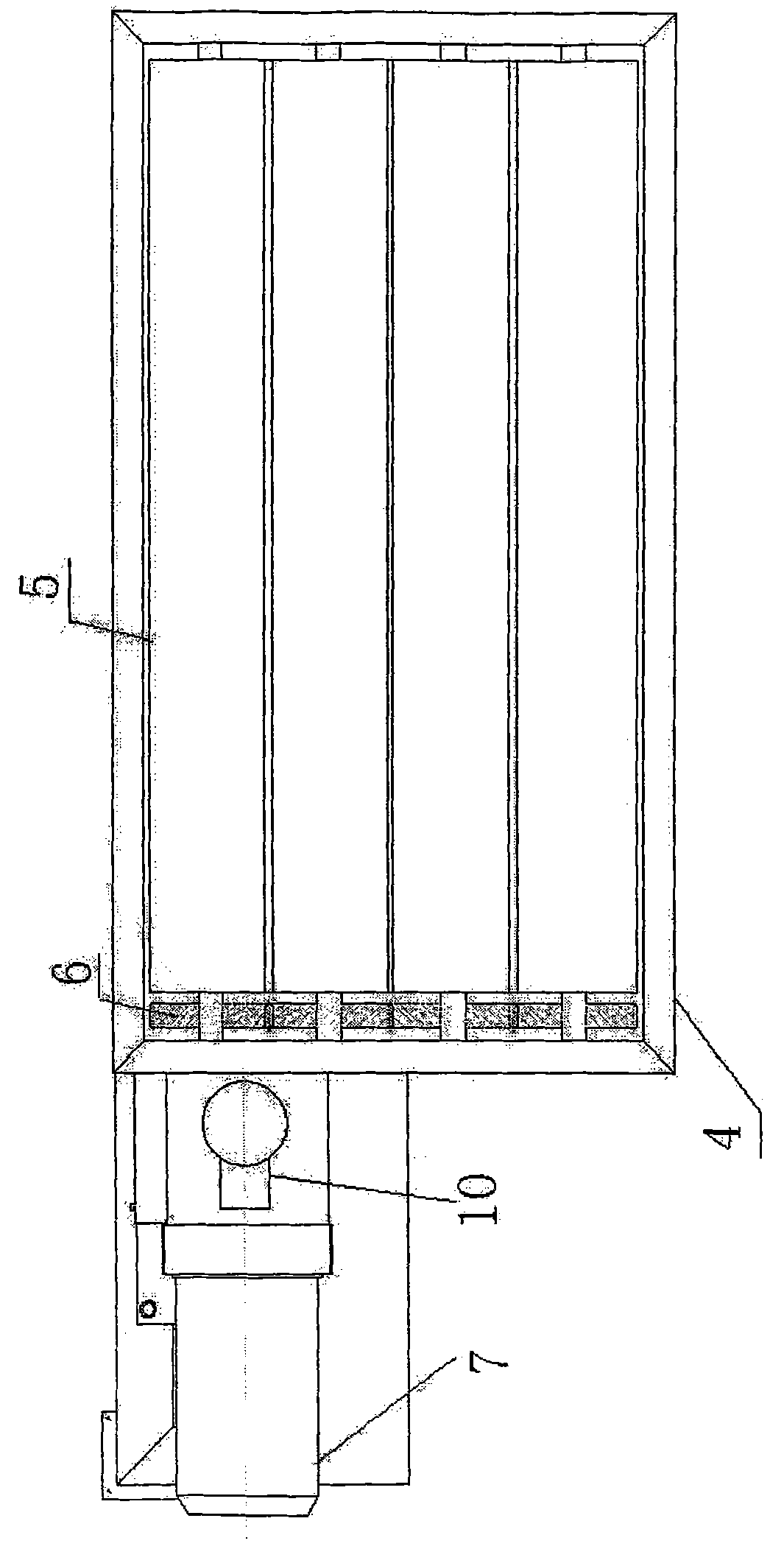

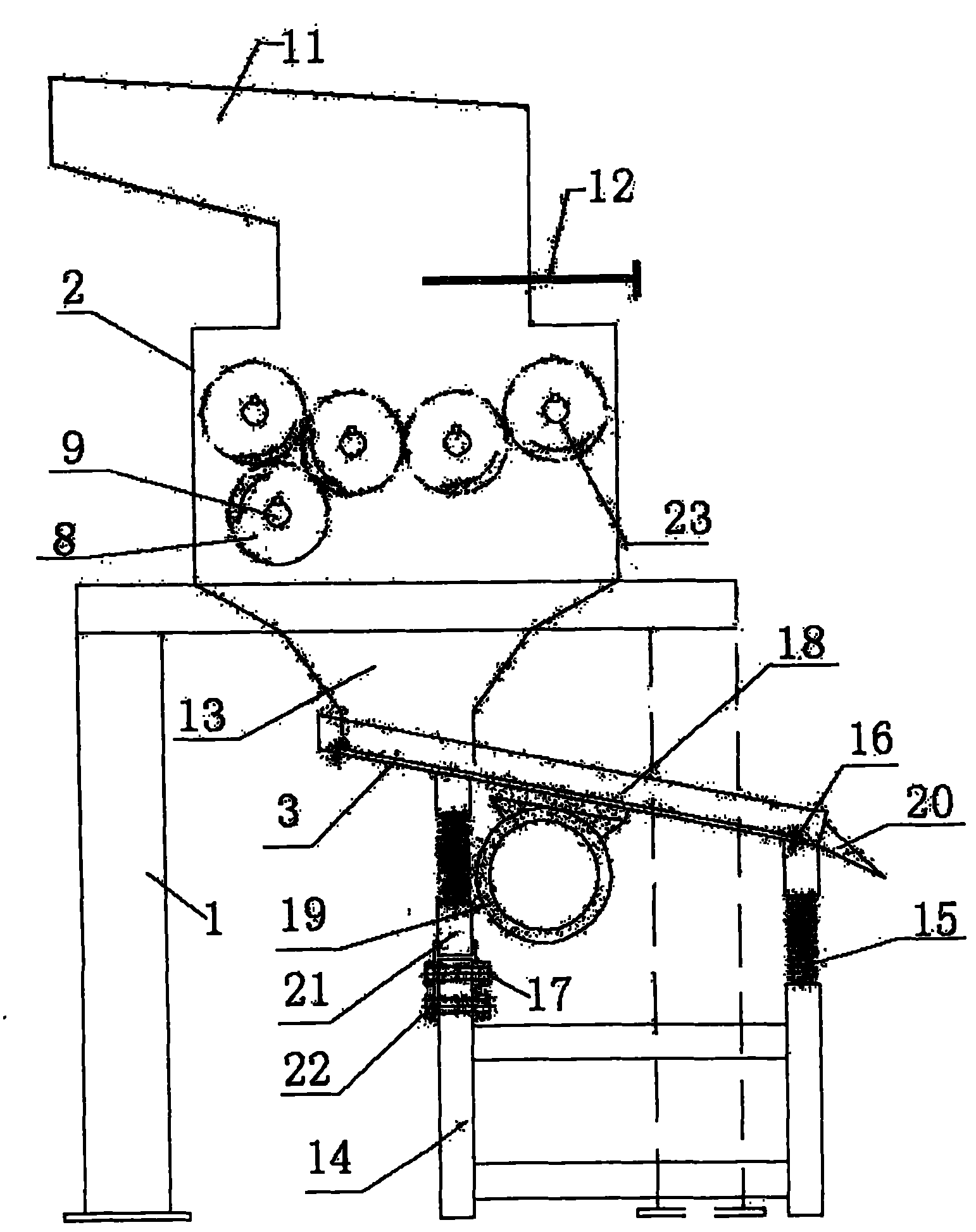

[0042] The method of dismantling and recycling waste ceramic resistors is as follows: the ceramic resistors are mainly composed of ceramic body and tin-plated copper-iron alloy pins, and the waste ceramic resistors are put into the rolling crusher through the feeding hopper 11 and the feeding regulating valve 12 2, the rolling crusher 2 is equipped with a plurality of pairs of rolling rollers or drums 5, and each pair of rolling rollers or drums is opposite to the rolling rollers or drums to roll and roll waste ceramic resistors, and the rolling rollers Or the drum is connected and driven by the drive motor 7, and a vibrating screening machine is installed under the rolling roller or the drum. The vibrating screen of the vibrating screening machine is installed at an inclination at a certain angle. Install a vibrating motor, and the vibrating motor is connected to vibrate. After the waste ceramic resistors are rolled by the rolling rollers or rollers, the ceramics are crushed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com