Method and equipment of aluminum capacitor disassembly and resource recovery

A technology of resource recovery and capacitors, applied in the removal of solid waste, grain treatment, etc., can solve the problems of landfill soil pollution, secondary environmental pollution, environmental pollution, etc., to achieve no waste gas generation, good environmental performance, separation and recovery efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

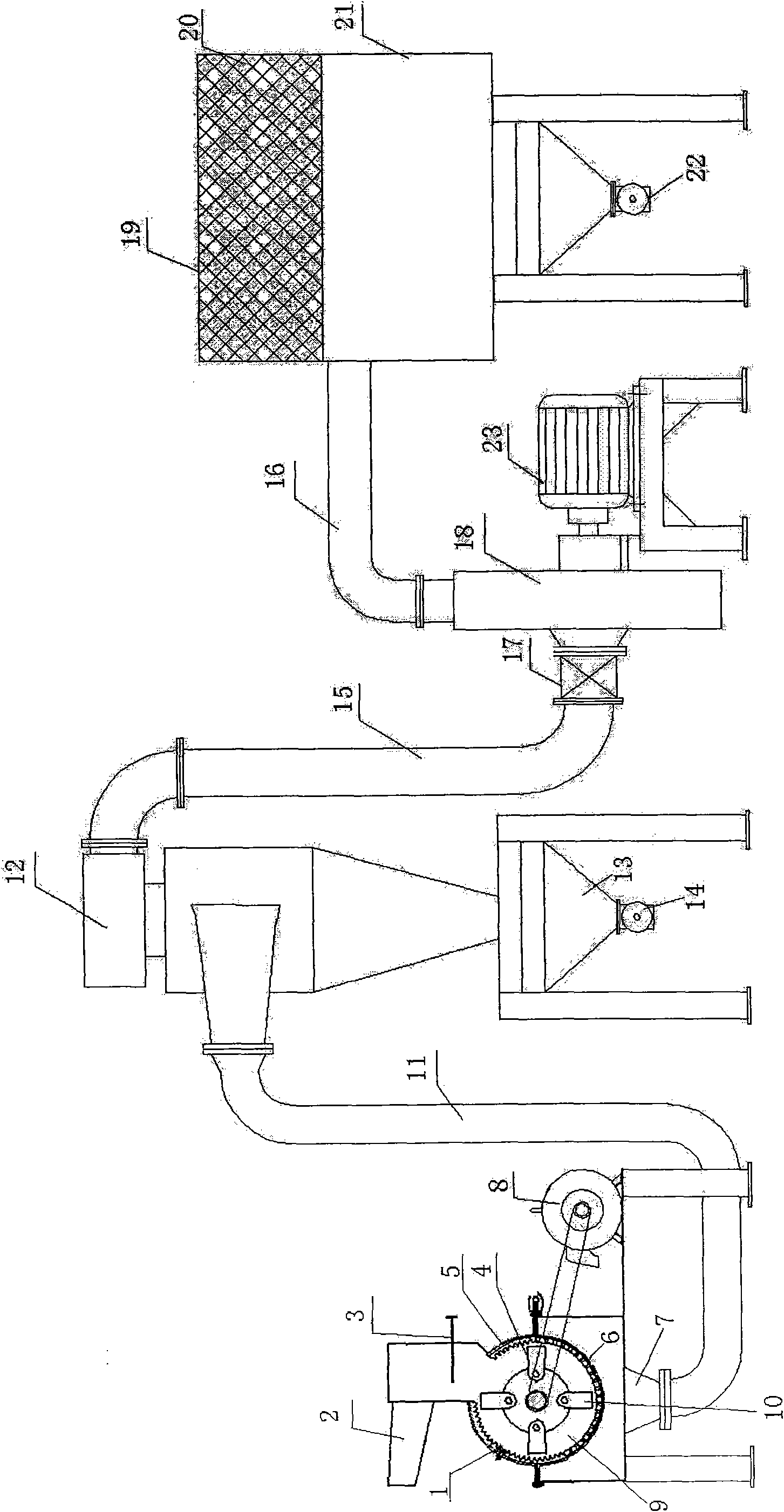

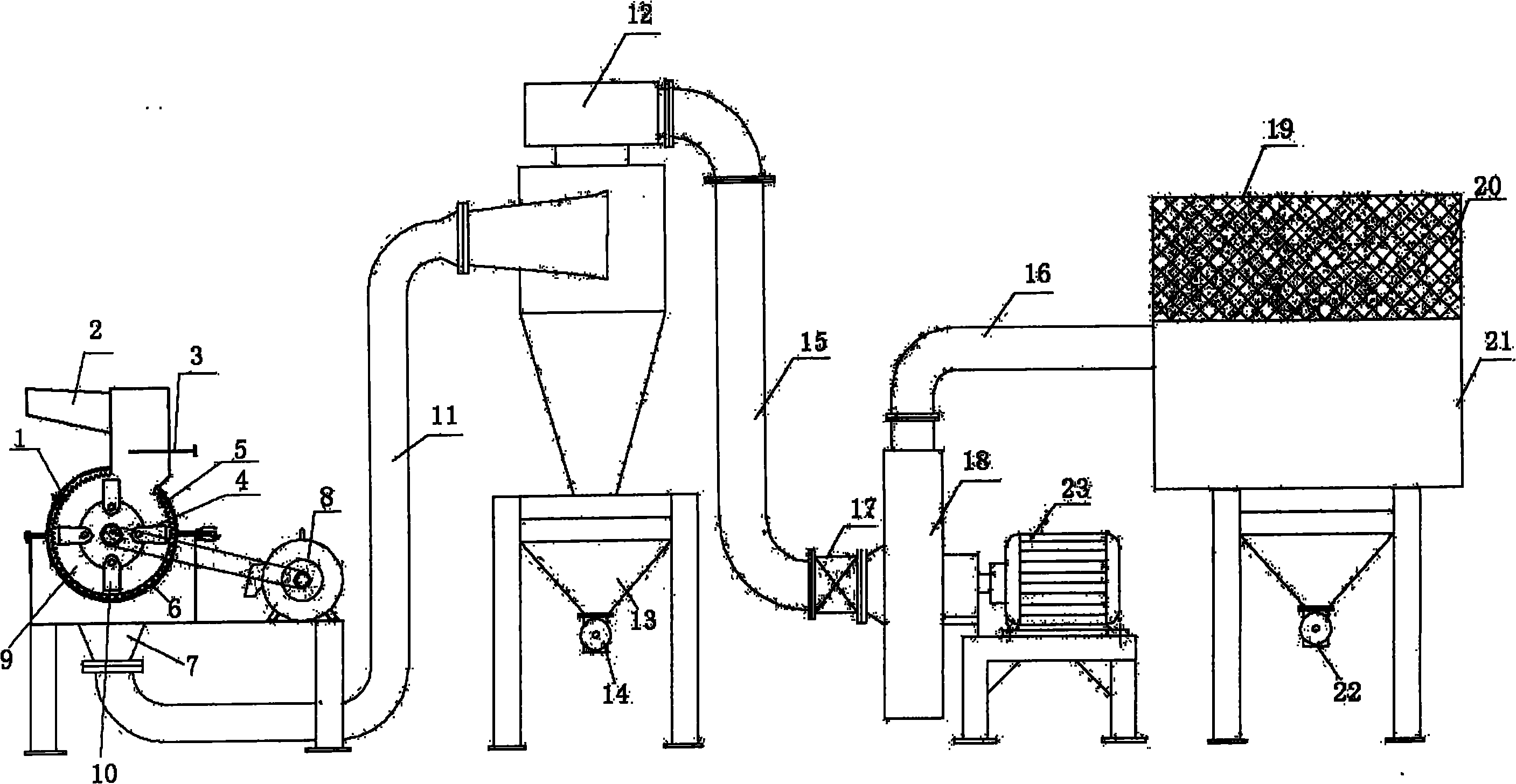

[0039] see figure 1 , the method of dismantling aluminum capacitors and recycling resources is as follows: first, the aluminum capacitors enter the hammer crushing chamber 9 from the feed hopper 2 and the feed regulating valve 3 of the hammer crusher 1, and the hammer crushing chamber 9 is The ring gear plate 5, the hammer prop 4 and its space are composed. The hammer prop 4 is driven to rotate by the crusher motor 8. There are multiple movable hammers 10 installed on the hammer prop, and a screen 6 is installed under the hammer crushing chamber 9. , the hammer-type crushing chamber crushes and separates the aluminum capacitor under the interaction of the heavy hammer 10 and the ring gear plate 5, separates the aluminum capacitor from the internal components, and breaks it into broken aluminum blocks and broken electrolytic paper; broken The aggregate is collected by the collecting hopper 7 after being sieved by the screen; the collecting hopper 7 undertakes the flow of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com