Direction converting device for flat glass

A technology of flat glass and direction conversion, which is applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., can solve the problem of long time, achieve the effect of rapid direction conversion, reduce waiting time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

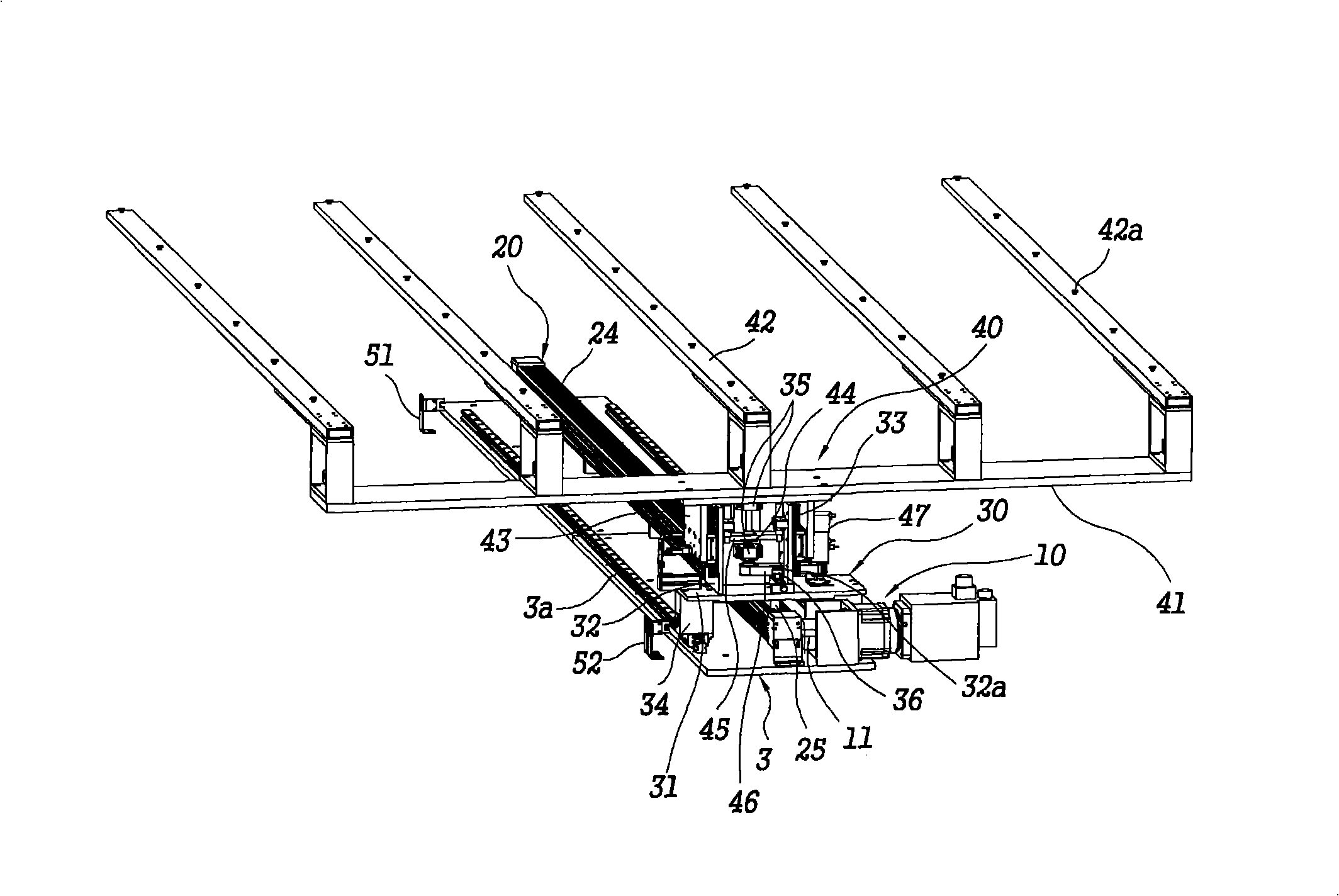

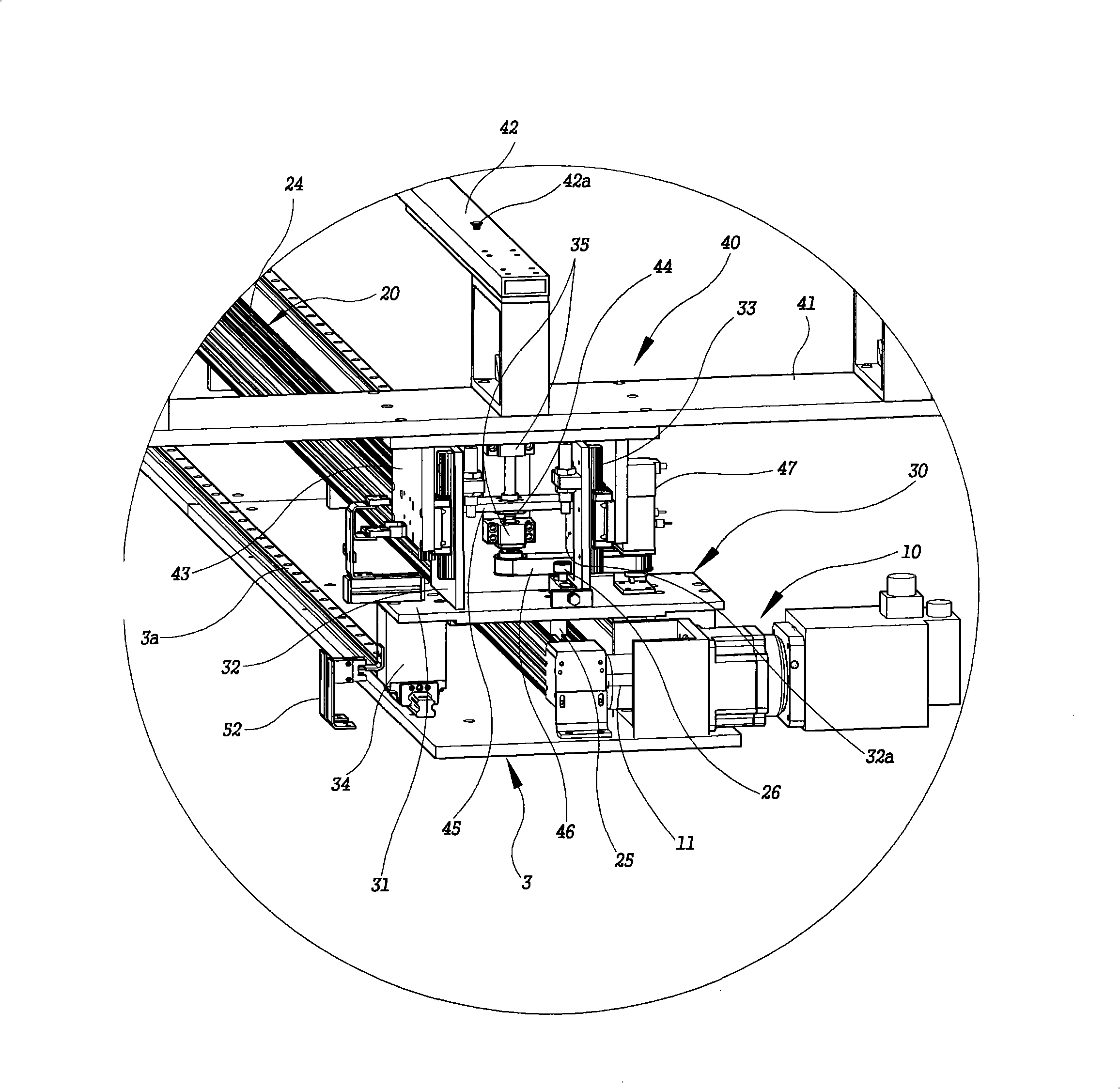

[0024] The present invention will be described below according to the figures in the appendix.

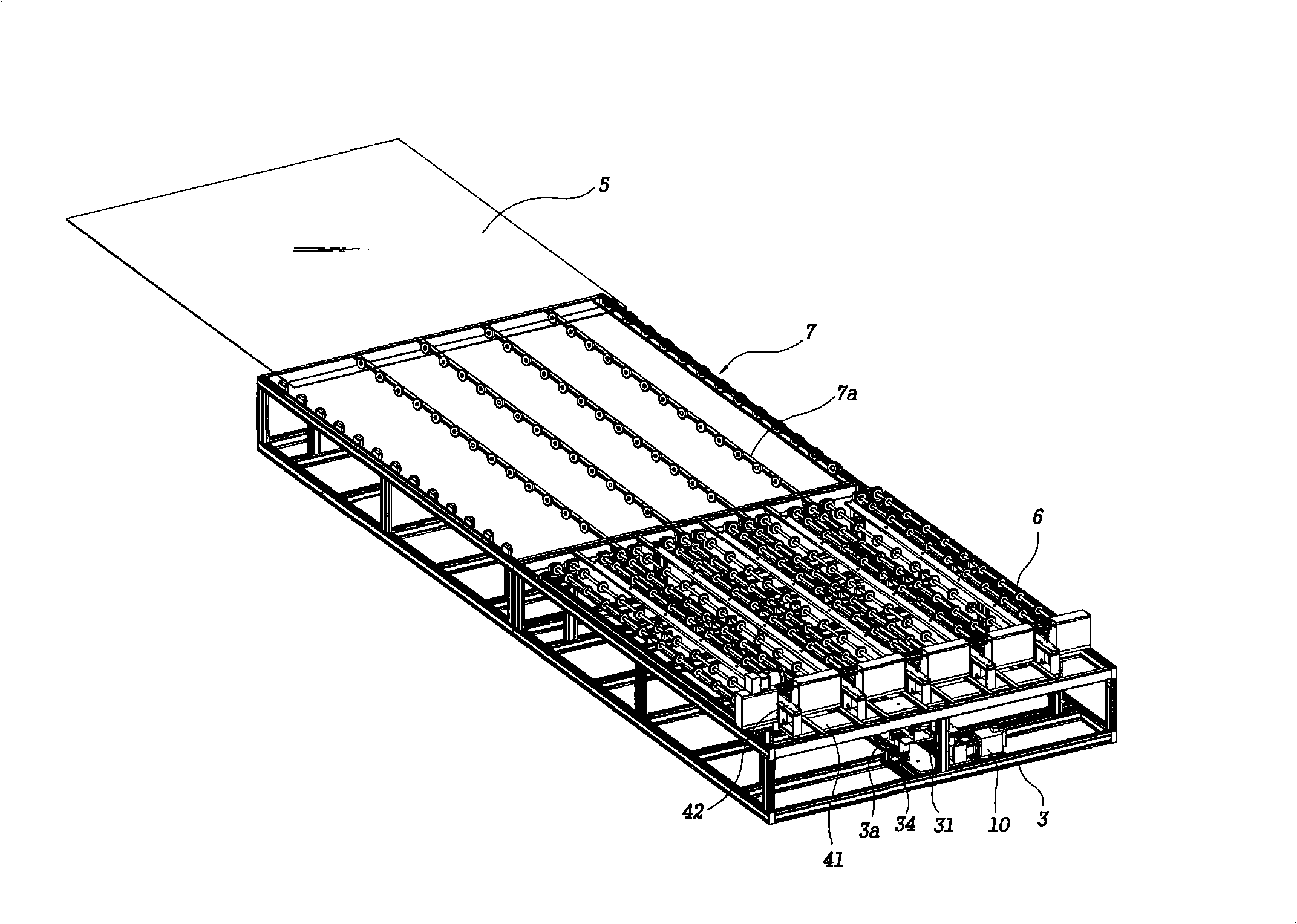

[0025] Such as Figure 1 to Figure 10 As shown, the direction conversion device for plate glass required for the implementation of the present invention includes: the entry guide mechanism that guides the plate glass 5 to the center of the main frame 5 provided on the main frame 3; the plate glass that will enter the main frame 3 The direction of 5 is converted into a direction at right angles to the direction of entry and the direction of the discharge mechanism is reversed;

[0026] The standby roller part 7 that is connected to the adjacent part of the main frame 3 in the direction of entry of the plate glass 5 to temporarily suspend the plate glass 5;

[0027] Here, the direction conversion discharge mechanism is to discharge the plate glass 5 conveyed into the main frame 3 by the entering guide mechanism; a plurality of rollers 6 are arranged on the shaft, and these rollers a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com